A glazed ceramic tile comprising a protective glaze layer and its manufacturing method

A manufacturing method and technology for protecting glaze, applied in the field of glazed ceramic tiles and their manufacturing, can solve the problems of blurred patterns, easy blockage, defects, etc., and achieve the effects of fast water volatilization, stable effect and favorable firing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

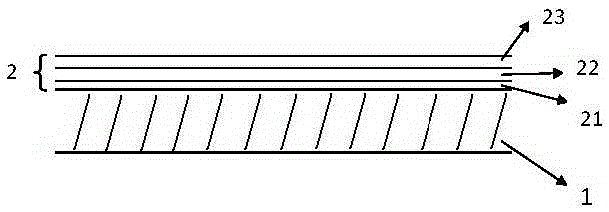

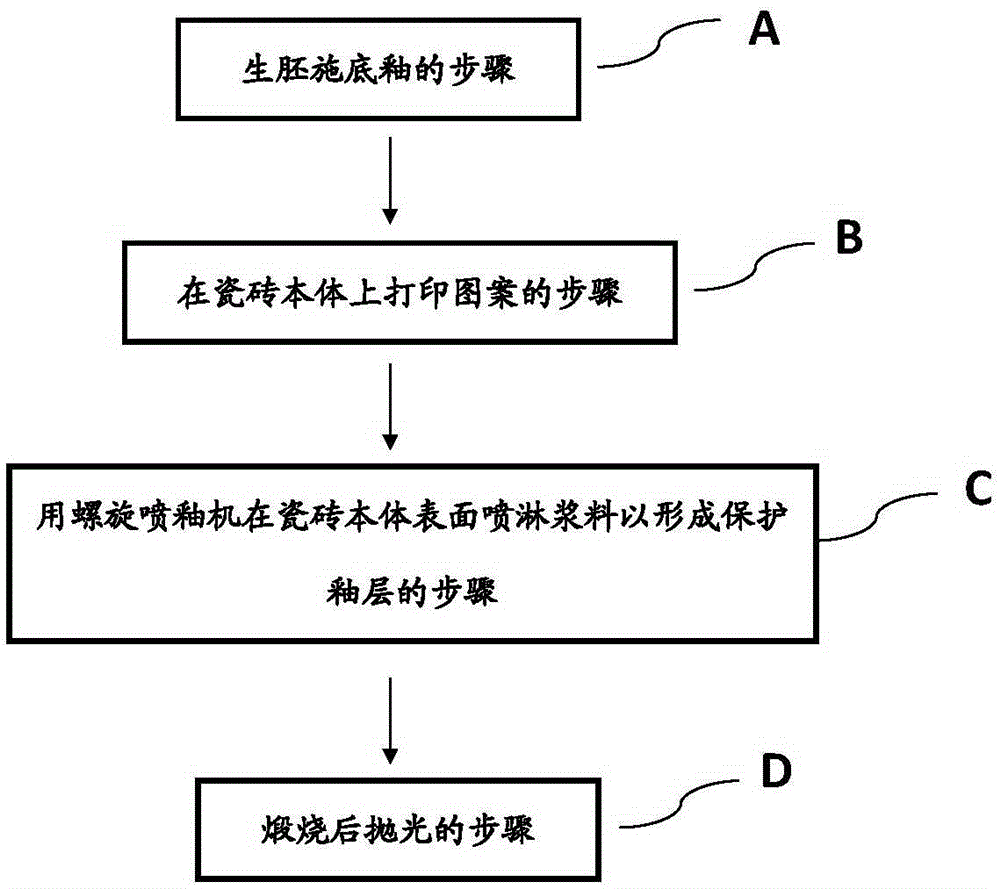

[0022] See figure 1 , that is, a cross-sectional view of a glazed ceramic tile comprising a protective glaze layer in the present invention. The glazed tile comprises a tile body 1 and a protective glaze layer 2 covering the surface of the tile body 1 . Wherein, the protective glaze layer 2 includes a plasticized film layer 21 , a transition layer 22 and a clinker frit transparent glaze layer 23 from bottom to top.

[0023] Further, the plasticized film layer 21 is an aqueous solution of tannin with a concentration of 1% to 10% by mass; the transition layer 22 is a transparent glaze slurry of low specific gravity raw material, that is, the specific gravity of the slurry is less than 1.20g / cm 3 Raw material transparent glaze slurry. Wherein, the plasticized film layer 21 has an isolation function and can form a layer of plasticized film on the pattern to ensure the clarity of the printed pattern. In actual production, the tannic acid aqueous solution with a mass percentage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com