Compound additive for inhibiting alkali metals from being transferred to gaseous phase in biomass combustion process and preparation method and application

A composite additive and combustion process technology, applied in the fuel, solid fuel, petroleum industry and other directions, can solve the problems of coking and slagging, low thermal efficiency, etc., and achieve the effect of increasing the ash melting point, reducing investment costs, and improving thermal efficiency and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

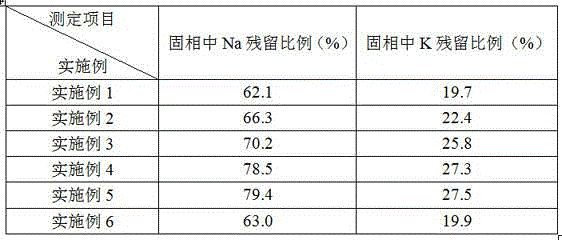

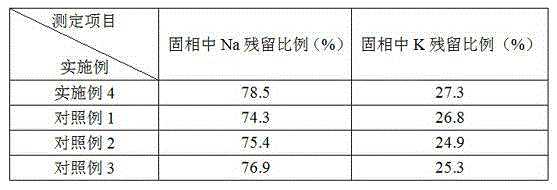

Examples

Embodiment 1

[0026] The composite additive provided in this embodiment for inhibiting the migration of alkali metals to the gas phase during biomass combustion is made of active ingredients and auxiliary materials, and the active ingredient is Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 , The auxiliary materials are binder and water, among which binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 The ratio of mass parts is 10:10:55:25, and the amount of water is binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 15% of the total mass.

[0027] The preparation method of the composite additive for inhibiting the migration of alkali metals to the gas phase during the combustion of biomass is as follows:

[0028] (1) According to the binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 The ratio of the mass parts is 10:10:55:25, weigh the binder and Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 , Wherein the binder is composed of starch and dextrin, and the mass ratio of starch and dextrin is 60:40. Mix them evenly in a drying container...

Embodiment 2

[0034] The composite additive provided in this embodiment for inhibiting the migration of alkali metals to the gas phase during biomass combustion is made of active ingredients and auxiliary materials, and the active ingredient is Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 , The auxiliary materials are binder and water, among which binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 The ratio of mass parts is 5:15:50:30, and the amount of water is binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 30% of the total mass.

[0035] The preparation method of the composite additive for inhibiting the migration of alkali metals to the gas phase during the combustion of biomass is as follows:

[0036] (1) According to the binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 The ratio of mass parts is 5:15:50:30, wherein the binder is composed of starch and dextrin, the mass ratio of starch and dextrin is 70:30, and the mixture is uniformly mixed in the drying container to obtain the mixture a;

[0037] (2) The partic...

Embodiment 3

[0042] The composite additive provided in this embodiment for inhibiting the migration of alkali metals to the gas phase during biomass combustion is made of active ingredients and auxiliary materials, and the active ingredient is Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 , The auxiliary materials are binder and water, among which binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 The ratio of mass parts is 20:20:40:20, and the amount of water is binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 20% of the total mass.

[0043] The preparation method of the composite additive for inhibiting the migration of alkali metals to the gas phase during the combustion of biomass is as follows:

[0044] (1) According to the binder, Al 2 O 3 , Kaolin and (NH 4 ) 2 SO 4 The ratio of mass parts is 20:20:40:20, and the binder is composed of starch and dextrin, and the mass ratio of starch and dextrin is 80:20. Mix them evenly in a drying container to obtain a mixture a;

[0045] (2) The particle size of the mixtur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap