Rail transit noise reduction box type bridge and external bonding noise reduction method of rail transit box type bridge

A technology for rail transit and box beams, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of inability to block low-frequency noise of bridges, high cost, and lack of noise reduction effect, achieving obvious noise reduction effect and preventing bridges. The effect of bending deformation and reducing low frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical content of the present invention will be further described below, but it is not intended to limit the essence of the present invention.

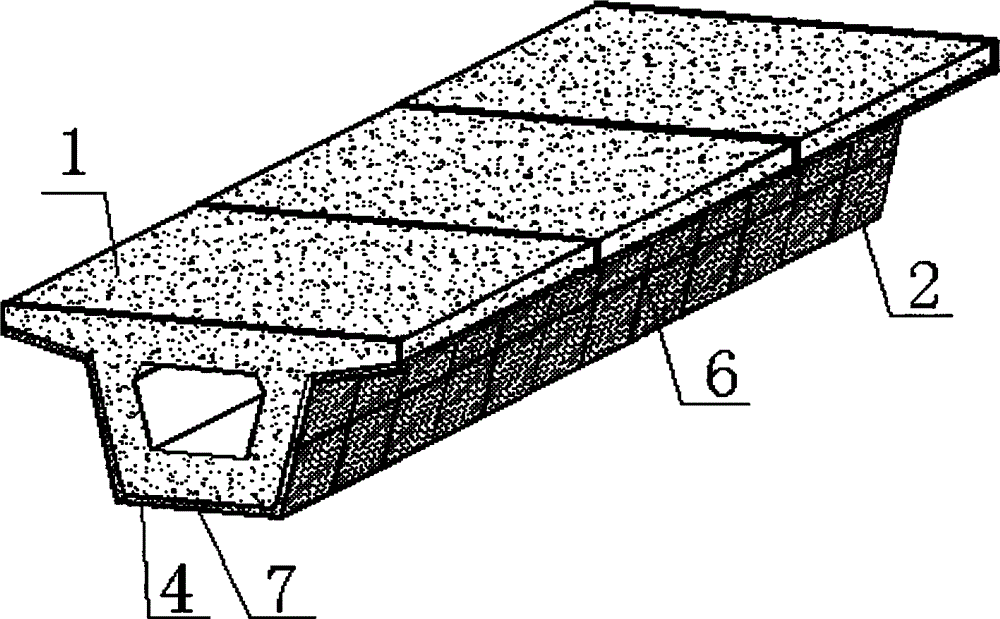

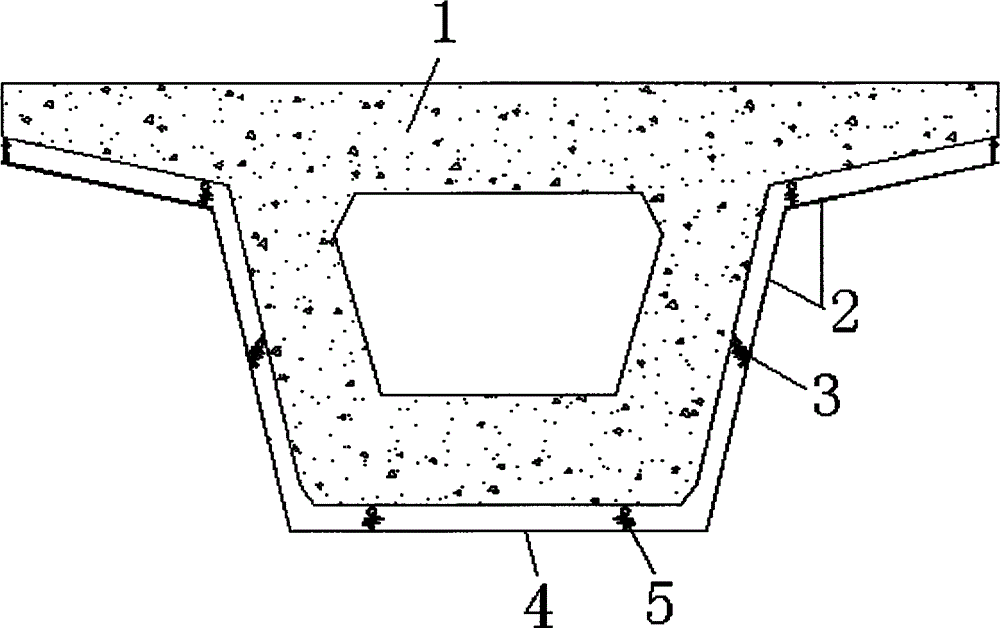

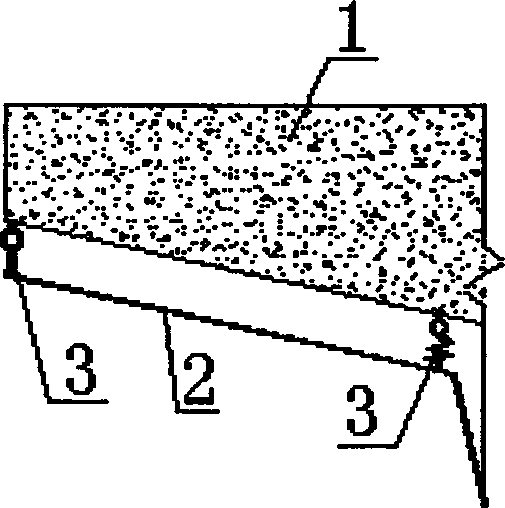

[0036] figure 1 It is a schematic structural view of a rail transit noise-reducing box-type bridge in an embodiment of the present invention; figure 2 It is a schematic diagram of the cross-sectional structure of a box beam according to an embodiment of the present invention; image 3 It is a partial schematic diagram of the cross section of the box beam flange plate of the embodiment of the present invention; Figure 4 It is a partial schematic diagram of the cross-section of the lower part of the box girder according to the embodiment of the present invention; Figure 5 It is a schematic diagram of the assembly structure of the sound-absorbing panel through the keel frame of the embodiment of the present invention; Figure 6 It is a schematic diagram of the connection structure of the side part and the lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com