Energy dissipation three-dimensional isolation bearing with oblique slide damping

A vibration isolation bearing and sliding damping technology, applied in the field of environmental vibration, earthquake resistance, and shock absorption, can solve the problems of restricting mass production, large shape, and high cost, so as to enhance the isolation effect, accelerate the attenuation rate, and effectively transmit vibration. The effect of decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

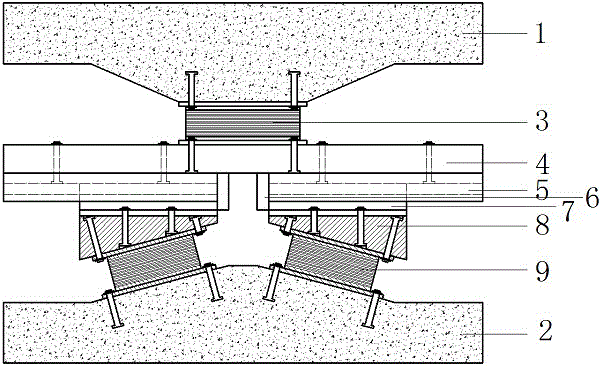

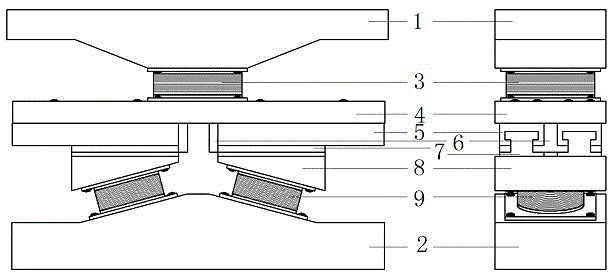

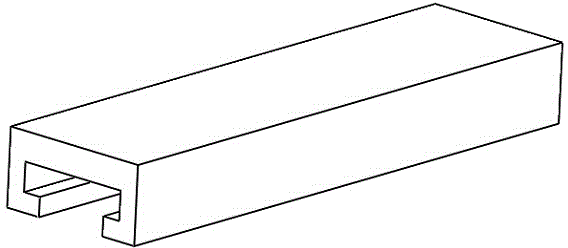

[0034] See figure 1 with figure 2 , The friction tensile three-dimensional seismic isolation support, including the upper structure 1, the lower foundation platform 2, the horizontal isolation support 3, the rigid connecting beam 4, the upper friction slot 5, the horizontal limit stop 6, the lower friction card Slot 7, connecting corner block 8, vertical seismic isolation support 9; characterized in that: the upper structure 1 and the horizontal seismic isolation support 3 are connected by bolts; the horizontal seismic isolation support 3 is fixed on the rigid connecting beam 4; The rigid connecting beam 4 is fixedly connected with the upper friction groove 5; the upper friction groove 5 and the lower friction groove 7 are interlocked with each other, and the contact surface is made of friction material. The friction coefficient of different materials varies within a certain range and can slide freely; The corner block 8 is a triangular prism body, which respectively fixedly co...

Embodiment 2

[0036] This embodiment is basically the same as the first embodiment, and the special features are as follows:

[0037] The vertical vibration isolation support 9 adopts a lead-core rubber support, and the two vertical vibration isolation supports 9 are placed obliquely to the horizontal in an "eight" shape. When subjected to vertical pressure, the upper friction card slot 5 and the lower friction card The groove 7 expands symmetrically and relatively slides, and the vertical seismic isolation support 9 undergoes compression and shear deformation.

[0038] The vertical vibration isolation support 9 adopts a lead-core rubber support, and the vertical vibration isolation support 9 is placed obliquely with a "V" shape and a horizontal line. When subjected to vertical pressure, the upper friction groove 5 and the lower friction groove 7 The symmetrical expansion and relative sliding occurs, and the vertical seismic isolation support 9 undergoes compression and shear deformation.

[0039...

Embodiment 3

[0043] Example three: see figure 1 —7. In this embodiment, the vertical vibration isolation unit adopts two sets of lead rubber bearings.

[0044] An oblique sliding damping energy dissipation three-dimensional seismic isolation support, including a three-dimensional seismic isolation unit arranged between a base cap 10 and an upper structure 1. The upper surface of the device is anchored with the upper structure, and the lower surface is connected with the inclined base cap Anchor, the three-dimensional seismic isolation device is formed by a horizontal seismic isolation unit, a friction energy dissipating unit and a vertical seismic isolation unit in series, specifically: the horizontal seismic isolation unit is a lead rubber bearing 3 mounted axially and vertically, and a lead rubber bearing One end of the seat is fixedly connected to the upper structure 1, and the other end is fixedly connected to the rigid connecting beam 4 to form a horizontal seismic isolation device, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com