CO2 flooding output gas separation and reinjection integrated method

A technology for producing gas, C2-C5, which is applied in chemical instruments and methods, mining fluids, earth drilling and production, etc., and can solve the problems of inability to integrate separation and recovery of produced gas, high energy consumption, and high equipment costs. To achieve the effects of less steps, enhanced recovery and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

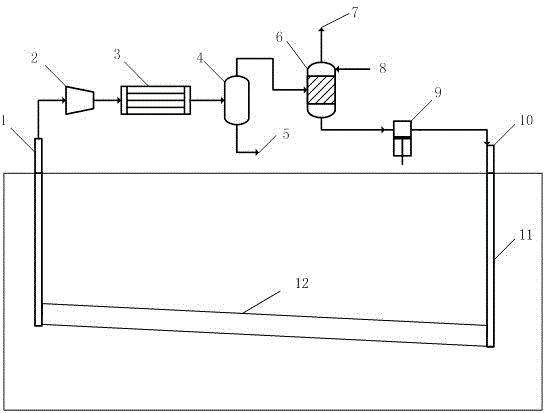

[0030] a CO 2 The integrated method of flooding production gas separation and reinjection, the specific steps are as follows:

[0031] (1) Produced gas pretreatment, separation of water vapor and C 6 The above heavy hydrocarbon components

[0032] Produced in Well 1 containing CH 4 , N 2 、C 2 -C 5 and C 6 The output gas of the above alkanes is the processing object, which is sequentially transported to the compressor 2 for pressurization through the gas transmission pipeline, the pressurized gas is cooled by the cooler 3, and the cooled fluid enters the gas-liquid separator 4, and in the separator 4 Separation of water vapor and C in the mixture 6 Above heavy hydrocarbons, water vapor and C 6 The above heavy hydrocarbons are discharged through the liquefied material outlet 5 at the bottom of the separator 4;

[0033] (2) Preparation of hydrate flooding agent

[0034] The mixed gas separated in the step (1) is discharged from the top of the separator 4 and passed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com