an intake muffler

A technology of air intake muffler and air intake port, which is applied in the field of air intake muffler to improve the high-frequency noise of intake air, and can solve the problems that the air filter cannot completely eliminate peaks, more peaks, and greater impact on NVH, so as to improve NVH performance, elimination of high-frequency components, and ease of installation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

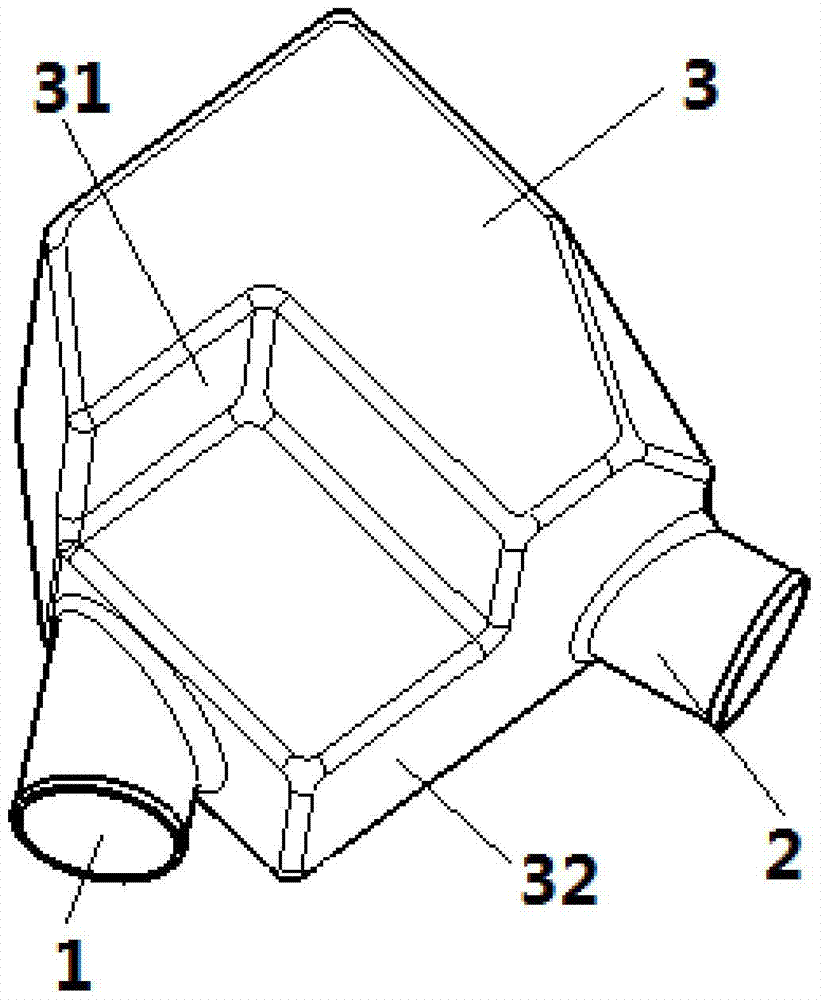

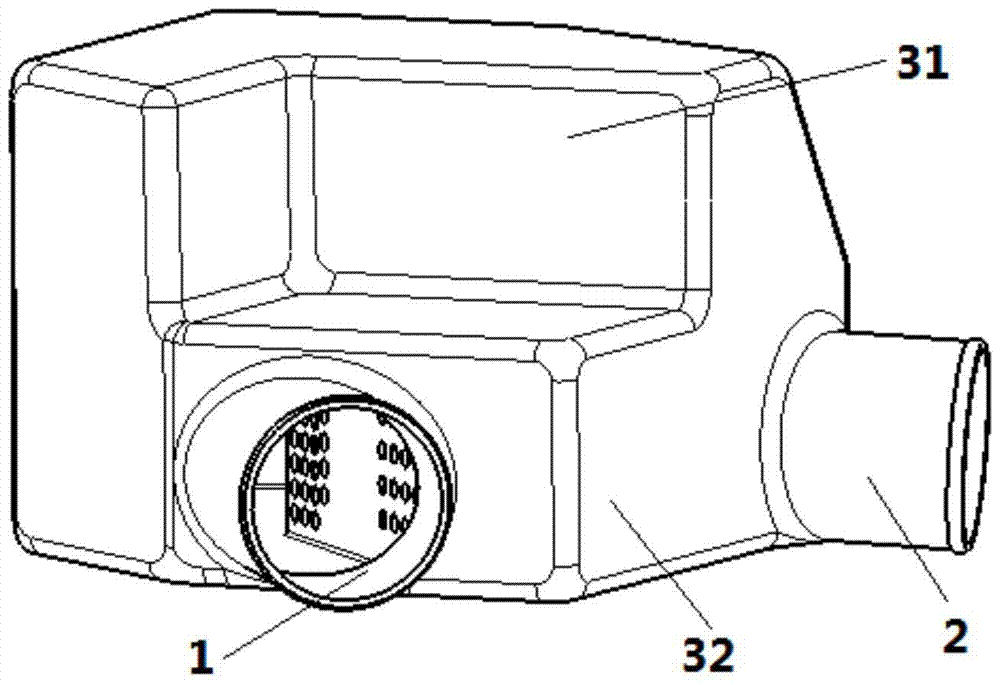

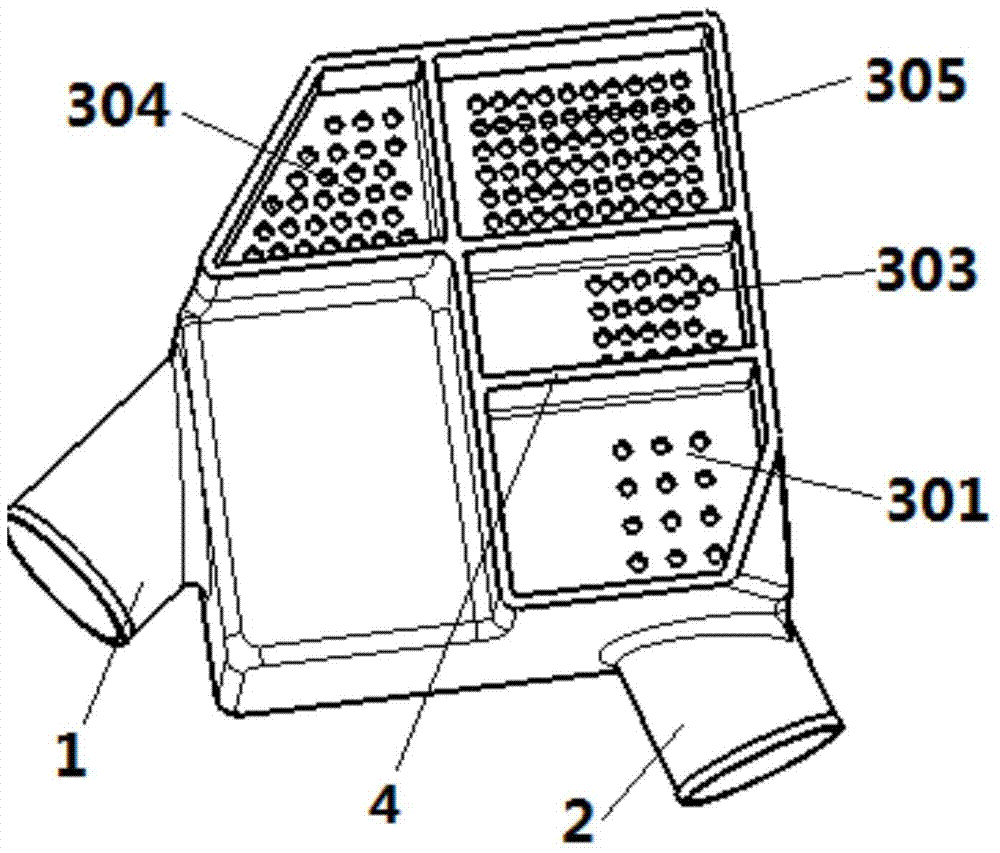

[0020] The intake muffler of the present invention is a kind of intake muffler for improving high-frequency noise, and is installed in front of the engine intake manifold (for supercharged engines, it should be arranged at the position after the intake manifold advances the intake air to be supercharged). Such as figure 1 , 2 As shown, the intake muffler includes a cavity 3 and an air inlet 1 and an air outlet 2 arranged on the cavity 3 and connected to the air intake pipe. The cavity 3 is divided into an upper cavity 31 and a lower cavity 32 by a partition plate. The upper cavity 31 and the lower cavity 32 are provided with a plurality of chambers with micro-perforations. The air inlet 1 and the air outlet 2 are arranged on the wall surface of the lower cavity 32 and communicate with the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com