Automatic-locking single-way transmission mechanism

A one-way transmission and automatic locking technology, applied in the direction of transmission, transmission parts, friction transmission, etc., can solve the problems of difficult assembly, high requirements on production materials, unfavorable control costs, etc., and achieves compact structure and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

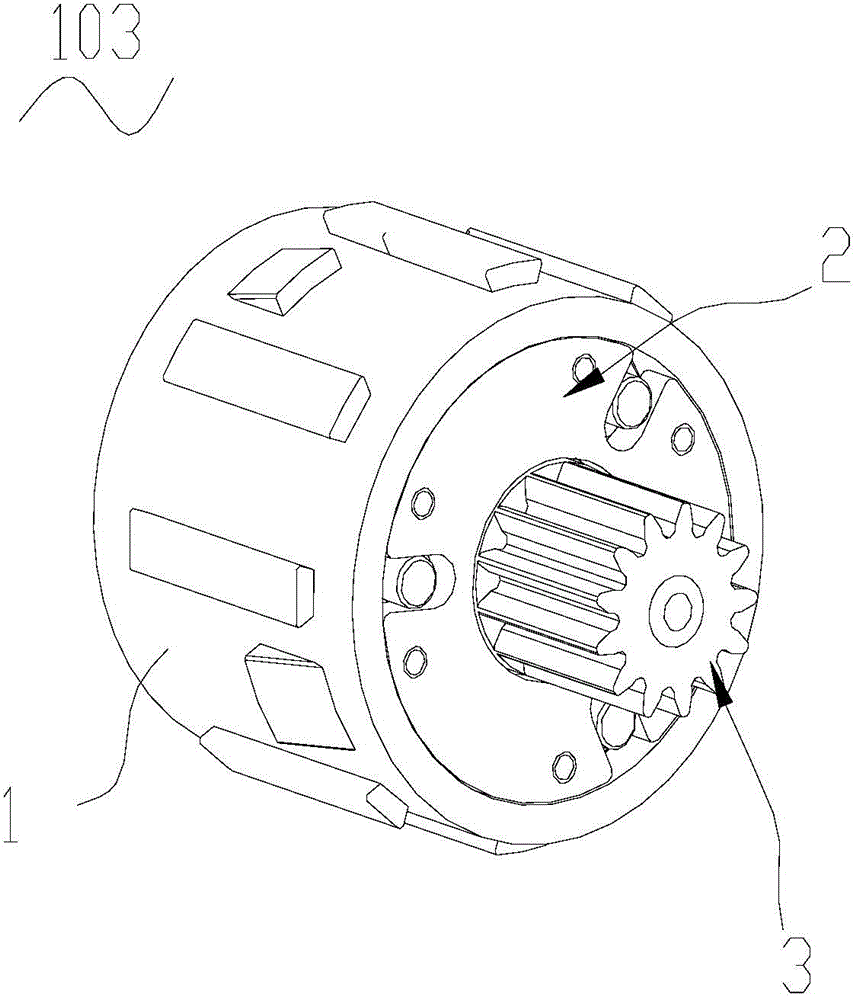

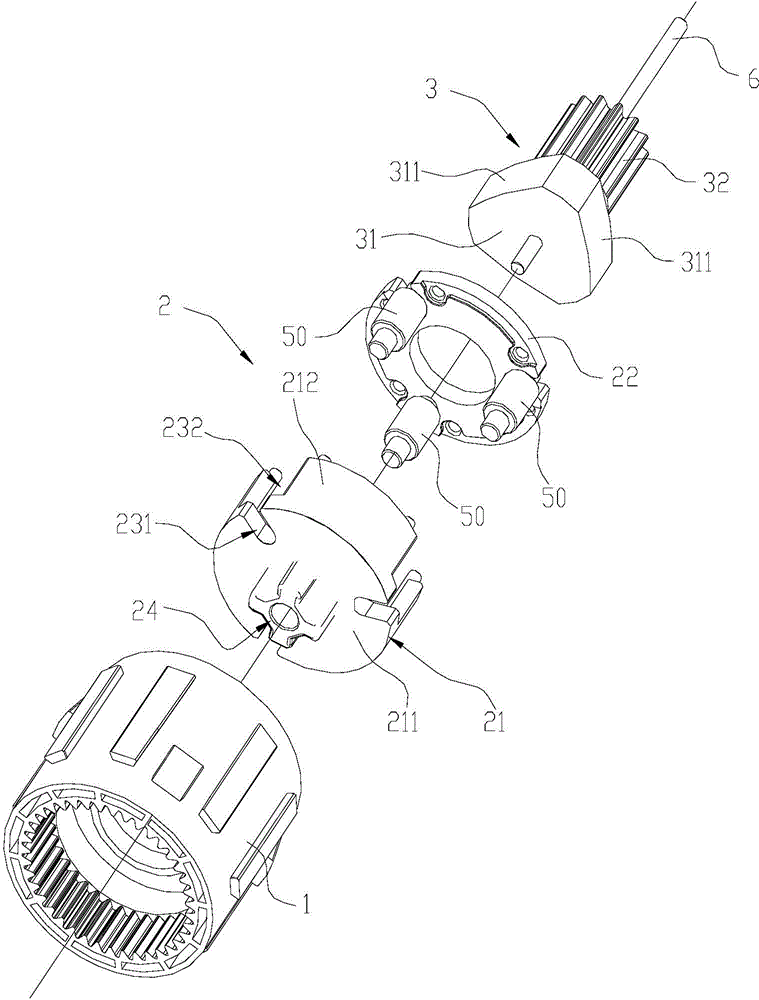

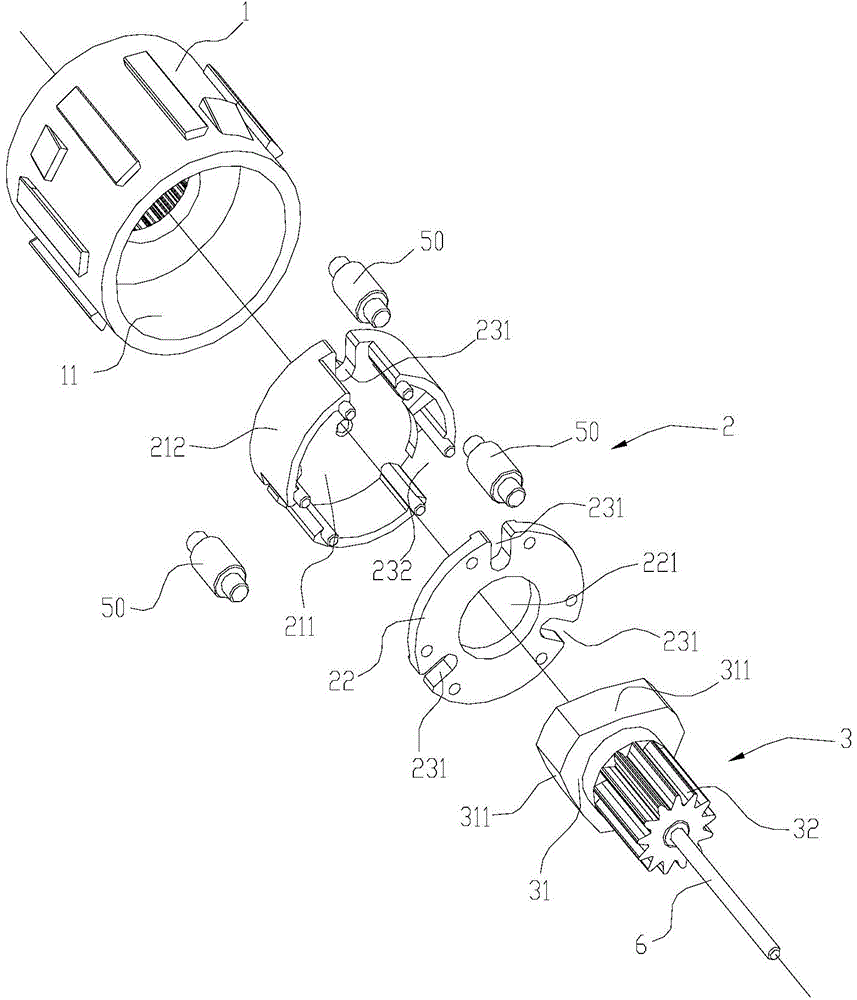

[0034] see Figure 1 to Figure 4 , which is a structural schematic diagram of a specific embodiment of the present invention, the self-locking one-way transmission mechanism 103 includes a main housing 1 , an input part 2 , an output part 3 and a ball assembly composed of three ball units 50 .

[0035] see Figure 1 to Figure 3 , the main housing 1 is roughly a cylindrical housing with two ends open, the inner cavity of the main housing 1 forms an installation cavity, and the inner hole wall of the main housing 1 forms a cylindrical friction surface 11, the main housing 1 The outer surface of 1 is provided with a fixing part (not shown in the figure) for fixing the main housing 1 on the external system; it is worth mentioning that the cross section of the friction surface 11 is not limited to a circle, but can also be an ellipse Or a polygon with roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com