Bidirectional electromagnetic valve for automobile brake systems

A technology of an automobile braking system and a two-way solenoid valve, which is applied in the field of solenoid valves, can solve problems such as the inability to achieve two-way sealing and the easy failure of the one-way solenoid valve seal, and achieve a novel and simple structure with no reduction in braking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

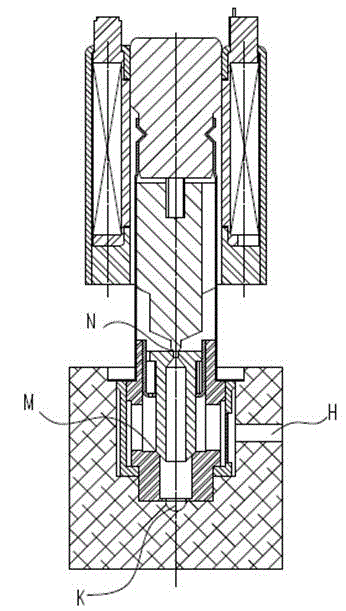

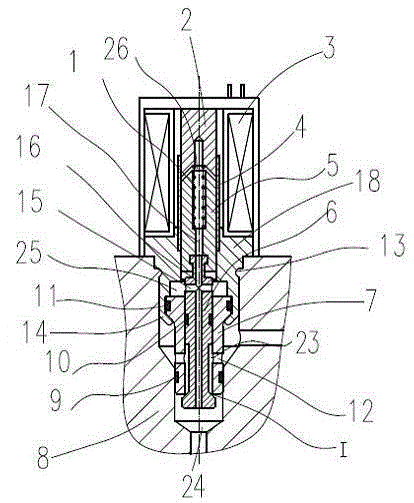

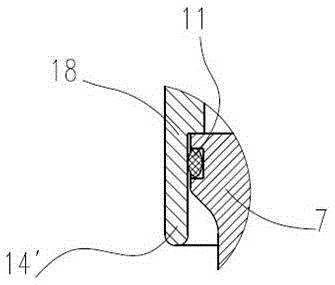

[0014] The fixed iron 2 is electromagnetic pure iron, the magnetic isolation tube 4 is stainless steel, the fixed iron 2 and the magnetic isolation tube 4 are laser welded, the magnetic isolation tube 4 is embedded in the valve body 18 and is laser welded with the valve body 18, the valve body 18 and the valve seat 7 Pressure riveting and fixed connection, the lower end surface of the valve body 18 is connected with the upper end surface of the valve seat 7, the inner circle of the valve body 18 and the outer circle of the valve seat 7 are radially sealed by the O-ring 211, and the flange 14 of the valve body is connected with the valve seat 7 The lower end of the moving iron 5 is assembled in the valve body 18, the upper end of the moving iron 5 is a 45-degree conical convex surface, the fixed iron 2 is located above the moving iron 5, the lower end of the fixed iron 2 is a 45-degree conical concave surface, and the middle of the moving iron 5 There is an axial step through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com