Large power ultrasonic sensor

An ultrasonic and sensor technology, applied in the field of high-power ultrasonic sensors, can solve problems such as weak bonding between piezoelectric ceramic sheets and metal shells, attenuation of piezoelectric performance of piezoelectric ceramics, and no piezoelectric performance of piezoelectric ceramics, achieving continuous The effects of longer working hours, higher mechanical quality factors, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

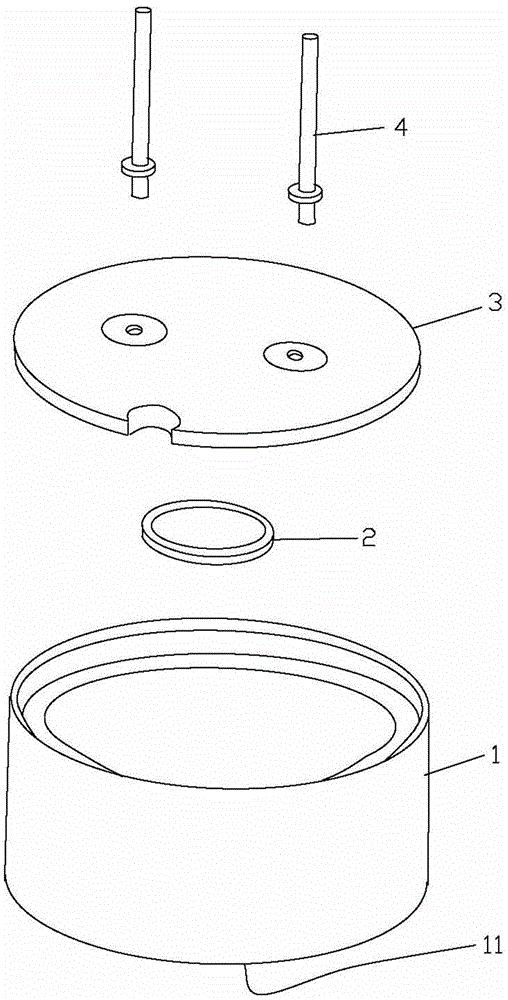

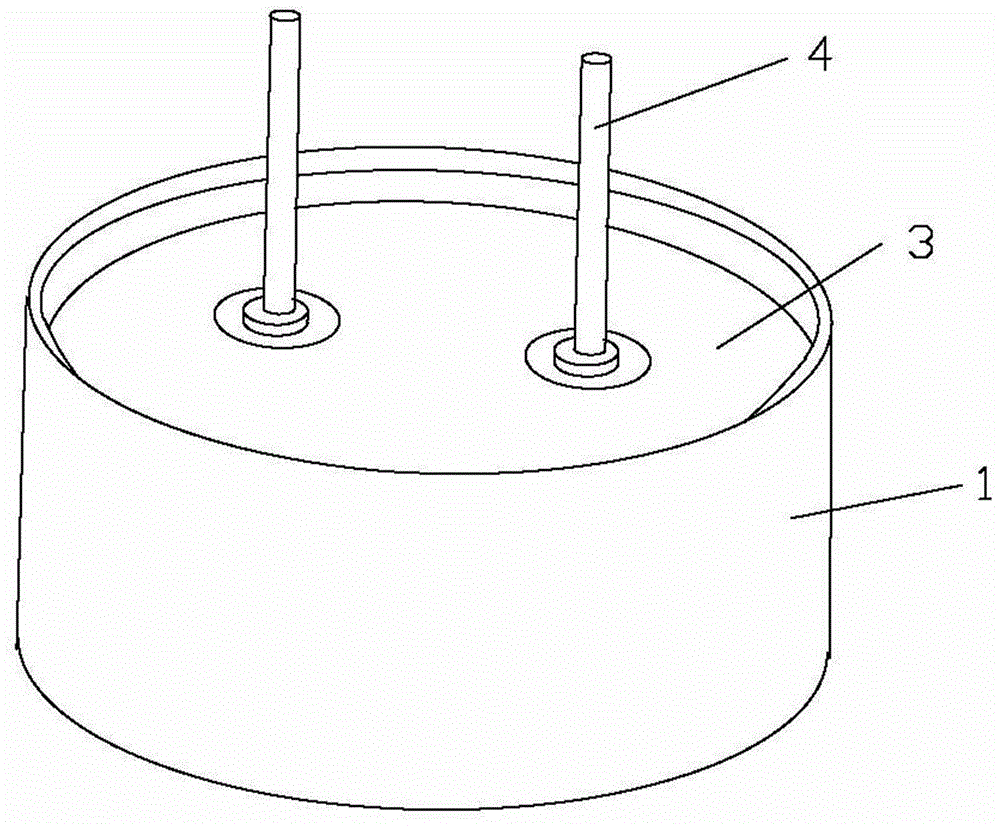

[0035] like Figure 1 to Figure 2 As shown, a high-power ultrasonic sensor includes a metal cylinder 1, a piezoelectric ceramic sheet 2 and a circuit board 3; one end of the metal cylinder 1 is formed with a bottom plate 11, and the bottom plate 11 and the metal cylinder 1 are an integral structure, and the metal cylinder The other end of the body 1 is open; the circuit board 3 is assembled with the other end of the metal cylinder 1; the piezoelectric ceramic sheet 2 is electrically connected to the circuit board 3;

[0036] The raw material composition of the piezoelectric ceramic sheet is as follows:

[0037] Lead oxide with the formula Pb(Mn 1 / 3 Sb 2 / 3 )O 3 ] 0.045 -[PbTiO 3 ] 0.4716 -[PbZrO 3 ] 0.4834 ;

[0038] Nickel oxide, the molecular formula is NiO, its weight is 0.01% of lead oxide;

[0039] Cerium oxide, molecular formula CeO 2 , its weight is 0.02% of the oxide of lead;

[0040] Cobalt oxide, the molecular formula is CO 2 o3 , whose weight is 0.01% of...

Embodiment 2

[0046] like Figure 1 to Figure 2 As shown, a high-power ultrasonic sensor includes a metal cylinder 1, a piezoelectric ceramic sheet 2 and a circuit board 3; one end of the metal cylinder 1 is formed with a bottom plate 11, and the bottom plate 11 and the metal cylinder 1 are an integral structure, and the metal cylinder The other end of the body 1 is open; the circuit board 3 is assembled with the other end of the metal cylinder 1; the piezoelectric ceramic sheet 2 is electrically connected to the circuit board 3;

[0047] The raw material composition of the piezoelectric ceramic sheet is as follows:

[0048] Lead oxide with the formula Pb(Mn 1 / 3 Sb 2 / 3 )O 3 ] 0.045 -[PbTiO 3 ] 0.4716 -[PbZrO 3 ] 0.4834 ;

[0049] Nickel oxide, the molecular formula is NiO, its weight is 0.01% of lead oxide;

[0050] Cerium oxide, molecular formula CeO 2 , its weight is 0.02% of the oxide of lead;

[0051] Cobalt oxide, the molecular formula is CO 2 o 3 , whose weight is 0.01% ...

Embodiment 3

[0057] like Figure 1 to Figure 2 As shown, a high-power ultrasonic sensor includes a metal cylinder 1, a piezoelectric ceramic sheet 2 and a circuit board 3; one end of the metal cylinder 1 is formed with a bottom plate 11, and the bottom plate 11 and the metal cylinder 1 are an integral structure, and the metal cylinder The other end of the body 1 is open; the circuit board 3 is assembled with the other end of the metal cylinder 1; the piezoelectric ceramic sheet 2 is electrically connected to the circuit board 3;

[0058] The raw material composition of the piezoelectric ceramic sheet is as follows:

[0059] Lead oxide with the formula Pb(Mn 1 / 3 Sb 2 / 3 )O 3 ] 0.045 -[PbTiO 3 ] 0.4716 -[PbZrO 3 ] 0.4834 ;

[0060] Nickel oxide, the molecular formula is NiO, its weight is 0.01% of lead oxide;

[0061] Cerium oxide, molecular formula CeO 2 , its weight is 0.02% of the oxide of lead;

[0062] Cobalt oxide, the molecular formula is CO 2 o 3 , whose weight is 0.01% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap