Method for measuring content of vanadium in nitrided ferrovanadium by oxidization and reduction

A technology of ferrovanadium nitride and content, which is applied in the direction of chemical analysis by titration method, to achieve the effect of saving drug cost, shortening time and improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

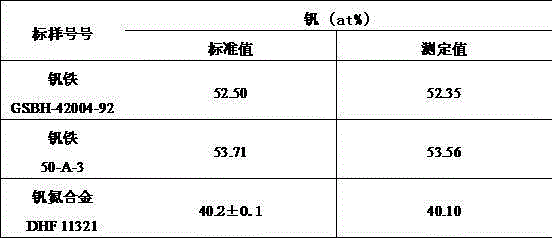

Examples

Embodiment Construction

[0017] 1. Method summary:

[0018] The sample is dissolved in nitric acid, heated to smoke by adding phosphoric acid, rapidly added with ammonium nitrate to oxidize low-valent vanadium, eliminated the interference of manganese with sodium nitrite, and titrated with ferrous ammonium sulfate as the standard solution.

[0019] 2. Reagents:

[0020] 2.1 Nitric acid solution (Nitric acid with a density of 1.42g / mL mixed with an equal volume of water)

[0021] 2.2 Phosphoric acid (density 1.68g / mL)

[0022] 2.3 Ammonium nitrate (solid)

[0023] 2.4 Sulfuric acid (50g / L)

[0024] 2.5 urea (100g / L)

[0025] 2.6 Sodium nitrite (10g / L)

[0026] 2.7 N-phenylanthranilic acid (2g / L): Weigh 0.2g of N-phenylanthranilic acid, dissolve it in sodium carbonate solution (2g / L) and dilute to 100mL.

[0027] 2.8 Standard solution of ferrous ammonium sulfate: 0.05000mol / L

[0028] 3. Sampling and sample preparation

[0029] 4. Sample size

[0030] Weigh the sample 0.1000g.

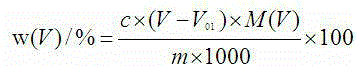

[0031] 5. Anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com