Real-time prediction method for catalytic reforming device

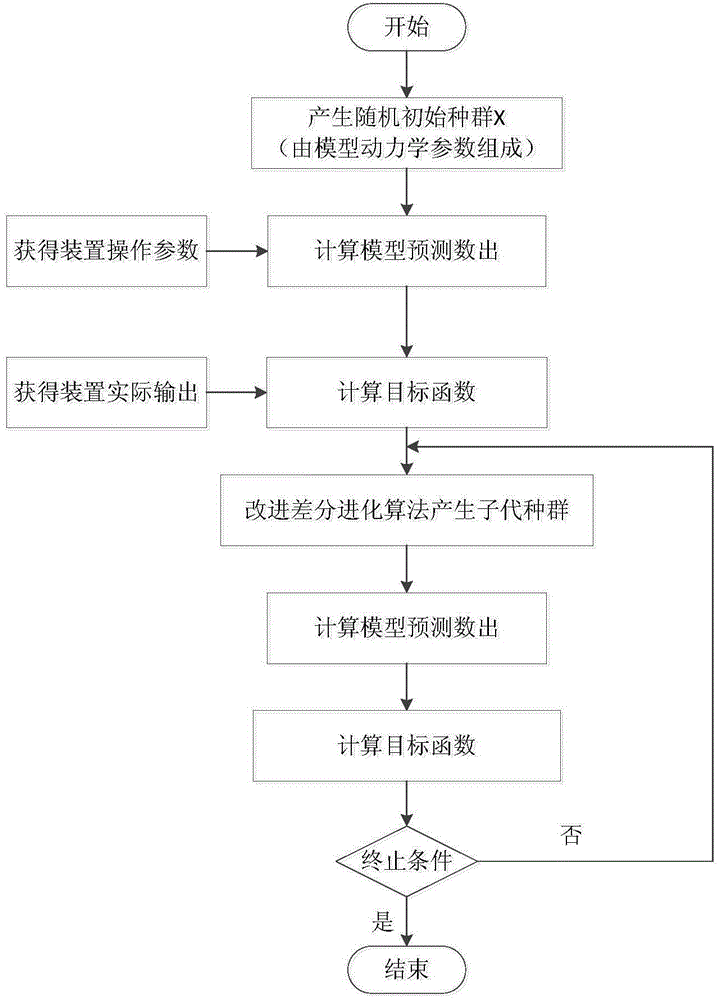

A real-time forecasting and catalytic reforming technology, applied in forecasting, data processing applications, calculations, etc., can solve problems such as difficult to accurately describe the operation process of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Mechanism modeling of catalytic reforming

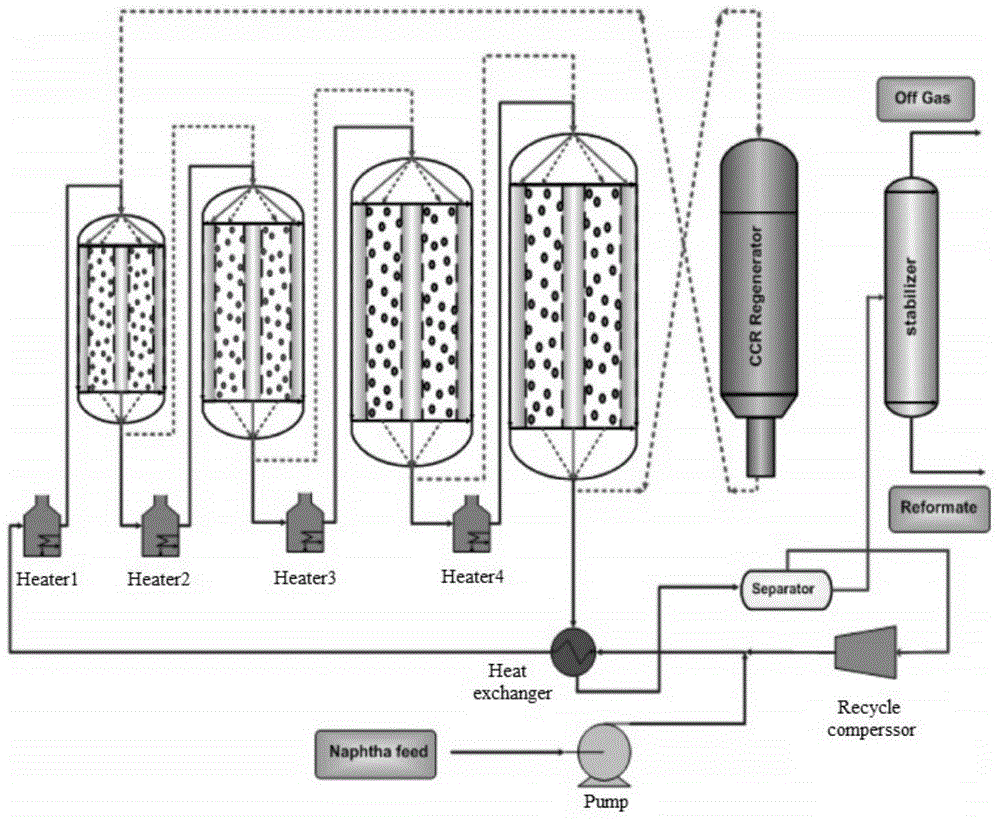

[0029] figure 1 It is a simplified flow chart of the continuous catalytic reforming process. The composition of naphtha feedstock in the catalytic reforming process is complex, and there are many reactions and side reactions. A large number of studies have shown that the reactions that occur in the catalytic reforming process can be divided into several categories, mainly including: (1) dehydrogenation of six-membered cycloalkanes to aromatics; (2) isomerization of five-membered cycloalkanes to six-membered cycloalkanes; (3) Isomerization of alkanes; (4) Dehydrocyclization of alkanes; (5) Hydrocracking of alkanes and cycloalkanes; (6) Demethylation (or hydrogenolysis) of alkanes and aromatics; (7) Aromatic dealkylation reaction; (8) carbon deposition reaction.

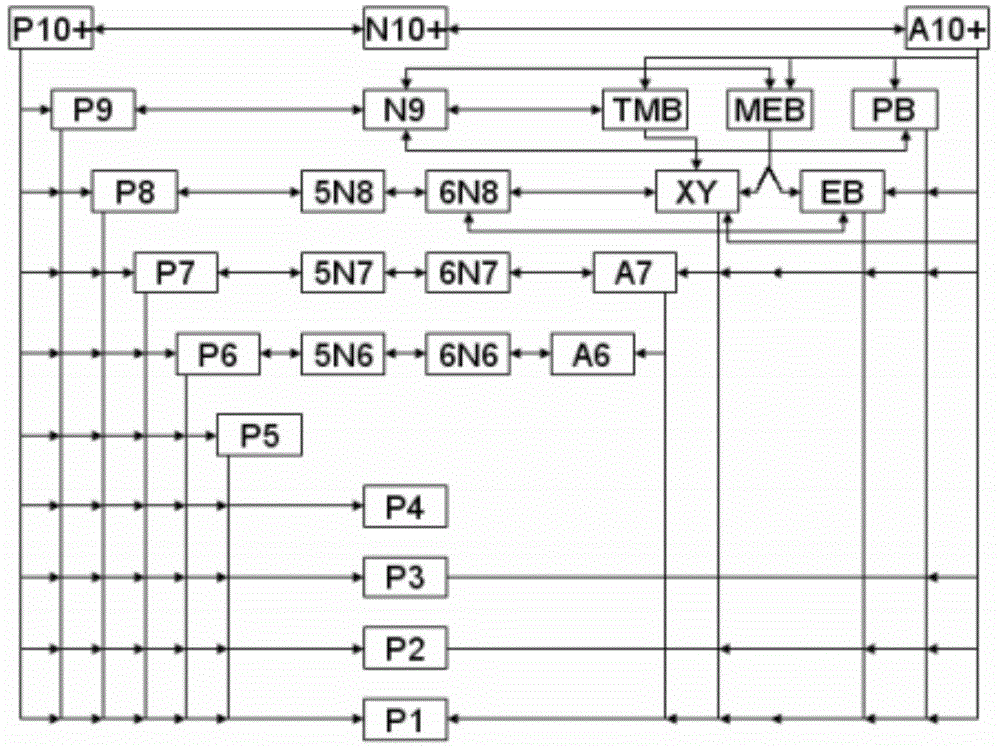

[0030] For the modeling of reaction kinetics of such a complex reaction system, a lumped kinetic model is required. The so-called lumping (Lumping) is to merge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com