High-performance piezoelectric longitudinal vibration energy harvester

An energy harvester, high-performance technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problems of poor adaptability and low reliability, and achieve reliable High performance, effective frequency bandwidth, and the effect of realizing low-frequency vibration energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

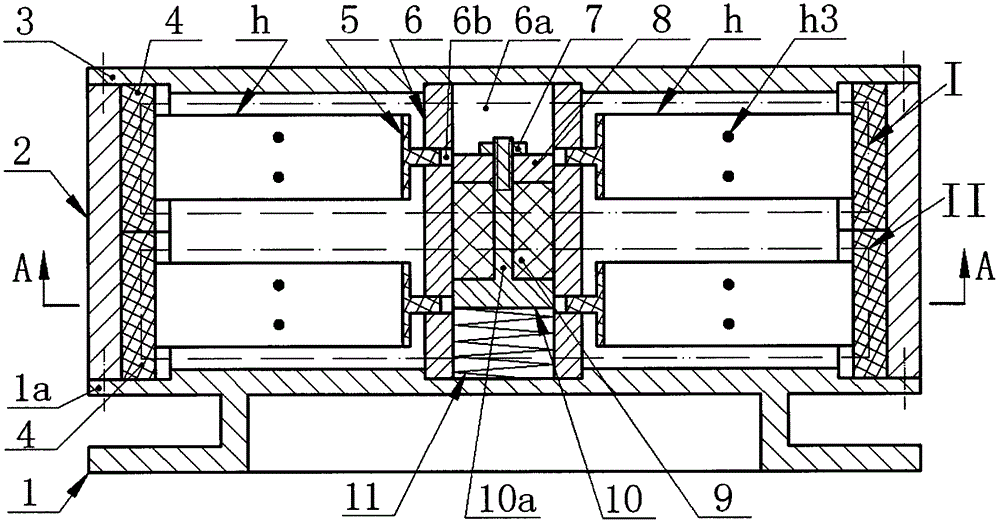

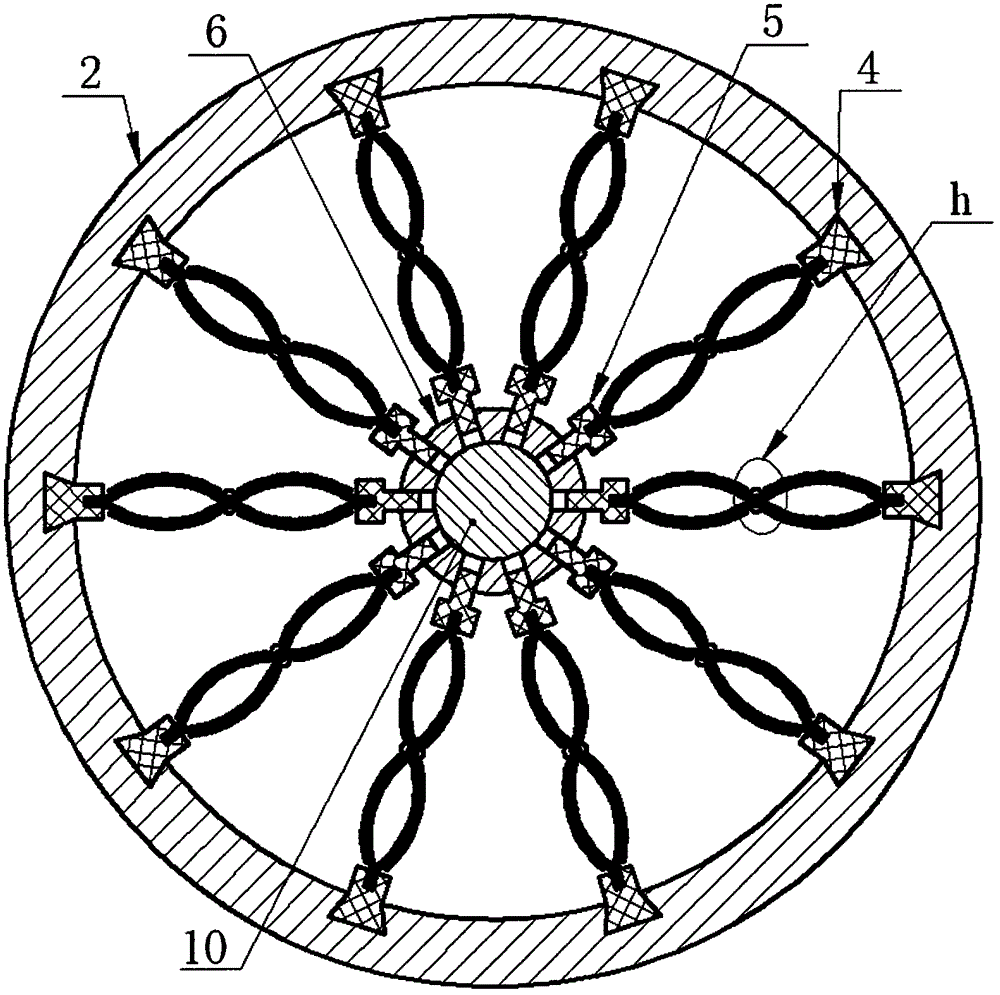

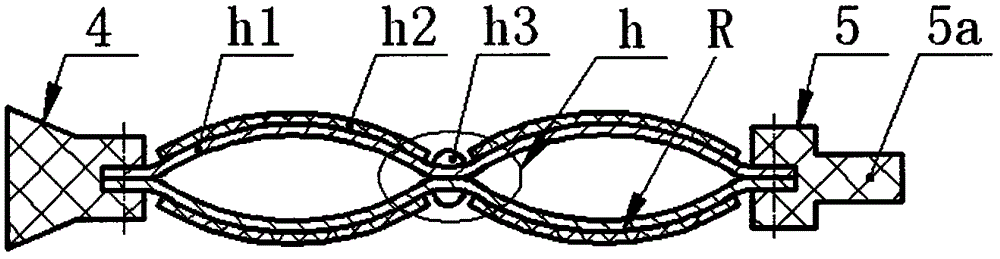

[0014] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the periphery and the center of the upper surface of the platen 1a of the support 1 are respectively provided with a stop ring and a counterbore, and the periphery and the center of the lower surface of the cover plate 3 are respectively provided with a stop ring and a counterbore; The outer cylinder 2 is installed between the seam ring on the periphery of the upper surface of the plate 1a and the seam ring on the periphery of the lower surface of the cover plate 3 through screws, and the counterbore on the upper surface of the platen 1a of the bracket 1 and the counterbore on the lower surface of the cover plate 3 An inner cylinder 6 is crimped between the holes; axial dovetail grooves are evenly distributed on the inner wall of the outer cylinder 2, and two sets of radial through holes 6b are evenly distributed on the side wall of the inner cylinder 6; The ring 9 is sequentially set on the column 10a of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com