Paddy rice sprout cultivation controlled release fertilizer and rice seed contact fertilizing apparatus

A technology of controlled-release fertilizer and rice seedling raising, which is applied in the field of contact fertilization devices between rice seedling raising controlled-release fertilizer and rice seed, which can solve problems such as inability to mix uniformly, nitrogen fertilizer loss, and easy stratification, so as to save labor and time costs, and continuously Sowing, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the drawings and embodiments.

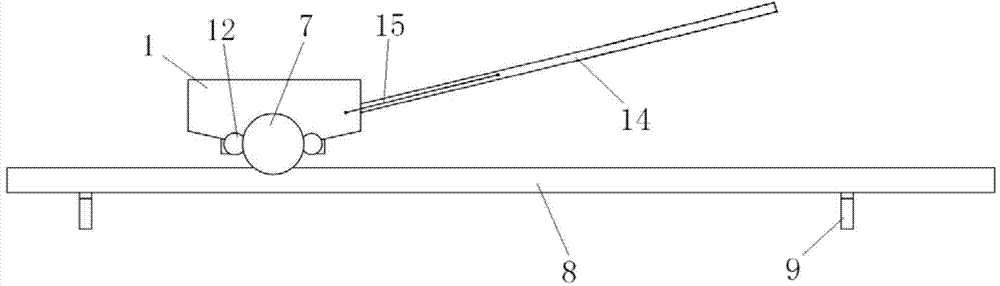

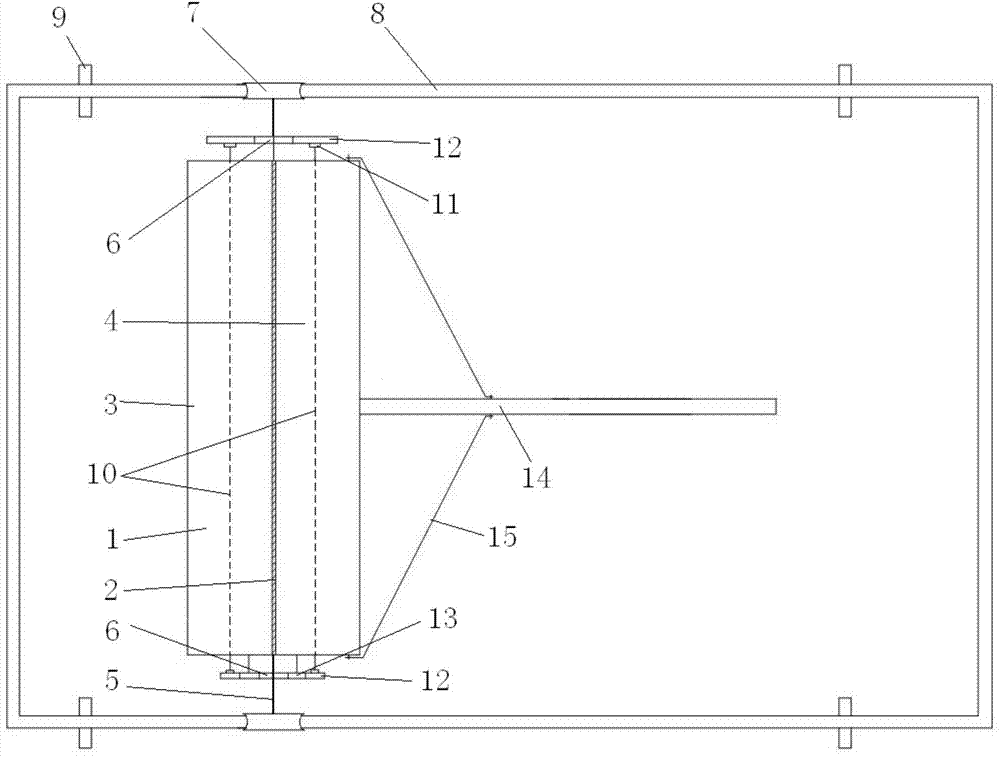

[0018] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a box body 1 in which a baffle plate 2 is vertically arranged to divide the box body 1 into a seed chamber 3 and a fertilizer chamber 4. A long rotating shaft 5 is rotatably arranged on the bottom surface of the box body 1, and both ends of the rotating shaft 5 are fixedly connected with a driving gear 6 and a running wheel 7 at intervals. Two running wheels 7 are located on two longitudinal guide rails of a rectangular track frame 8. Four rollers 9 are provided at the bottom of the rectangular track frame 8. The rollers 9 can make the rectangular track frame 8 move longitudinally or laterally.

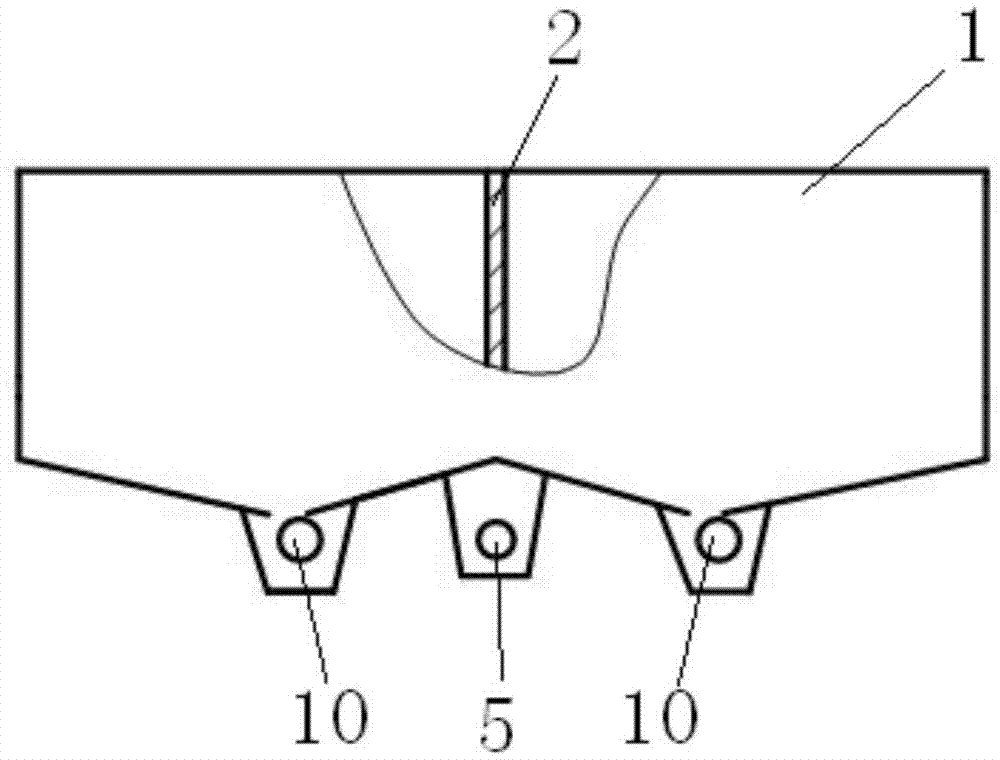

[0019] Such as figure 2 , image 3 As shown, the box body 1 located on the bottom surface of the seed chamber 3 and the fertilizer chamber 4 is respectively connected to a long shaft 10 in r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com