Tuoyan for pipe smoking and preparation method thereof

A technology for tuoting and smoking pipes, which is applied in the field of tobacco and can solve the problems that cannot be commercialized and freely circulated, and that troubles tobacco leaf products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

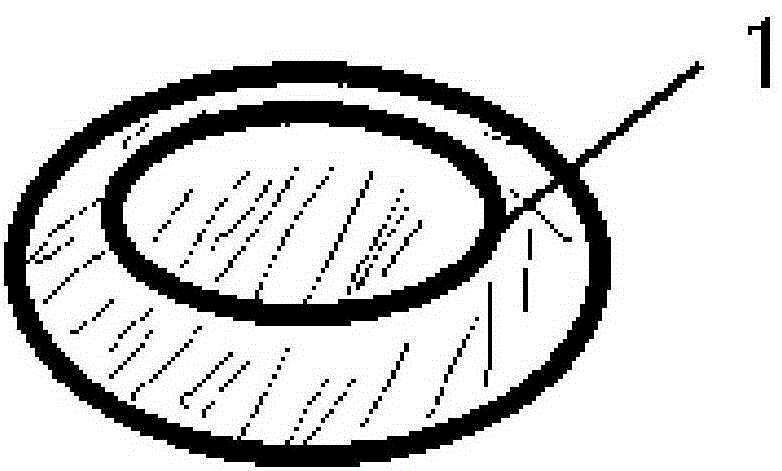

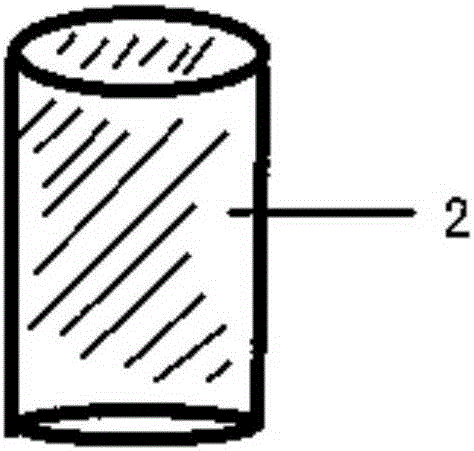

Image

Examples

Embodiment 1

[0022] A Tuo tobacco used for pipe smoking, which is composed of shredded tobacco, binder, moisturizing agent and water, wherein it is made of the following parts by weight: 85 parts of shredded tobacco, 3 parts of sodium carboxymethyl cellulose, 2 parts of propylene glycol, and 10 parts of water Part, the preparation method of the Tuoyan that is used for pipe smoking, comprises the steps:

[0023] (1) Tobacco leaves are used as the basic raw material. After the leaves are cut vertically by a cigarette cutter, the tobacco leaves enter the loosening and dampening machine. The moisture content of the loosened and dampened tobacco sheets is between 17.0 and 20.0, and the temperature is between 55.0 and 75.0°C.

[0024] (2) Shredded: After blending the cut leaves of various varieties and grades evenly, the tobacco leaves are made into shredded tobacco with a length of less than 2mm and a width of less than 0.5mm by using a fully automatic tobacco shredding line;

[0025] (3) Blend...

Embodiment 2

[0031] A Tuo tobacco used for pipe smoking, which is composed of shredded tobacco, binder, moisturizing agent and water, wherein it is made of the following parts by weight: 84 parts of shredded tobacco, 2 parts of sodium carboxymethyl cellulose, 3 parts of propylene glycol, and 11 parts of water share.

[0032] A method for preparing Tuo tobacco with a fixed form for pipe smoking, comprising the following steps:

[0033] (1) Tobacco leaves are used as the basic raw material. After the leaves are cut vertically by a cigarette cutter, the tobacco leaves enter the loosening and dampening machine. The moisture content of the loosened and dampened tobacco sheets is between 17.0 and 20.0, and the temperature is between 55.0 and 75.0°C.

[0034] (2) Shredded: After blending the cut leaves of various varieties and grades evenly, the tobacco leaves are made into shredded tobacco with a length of less than 2mm and a width of less than 0.5mm by using a fully automatic tobacco shredding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com