Automatic temperature control dual-horizontal shaft asphalt mixture mixing machine for laboratory

A technology of asphalt mixture and automatic temperature control, which is applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems affecting the accuracy of road performance experiments of mixtures, the decline of fatigue resistance of asphalt mixtures, Penetration and elongation are reduced to achieve the effects of shortening mixing time, strong practicability and reliability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

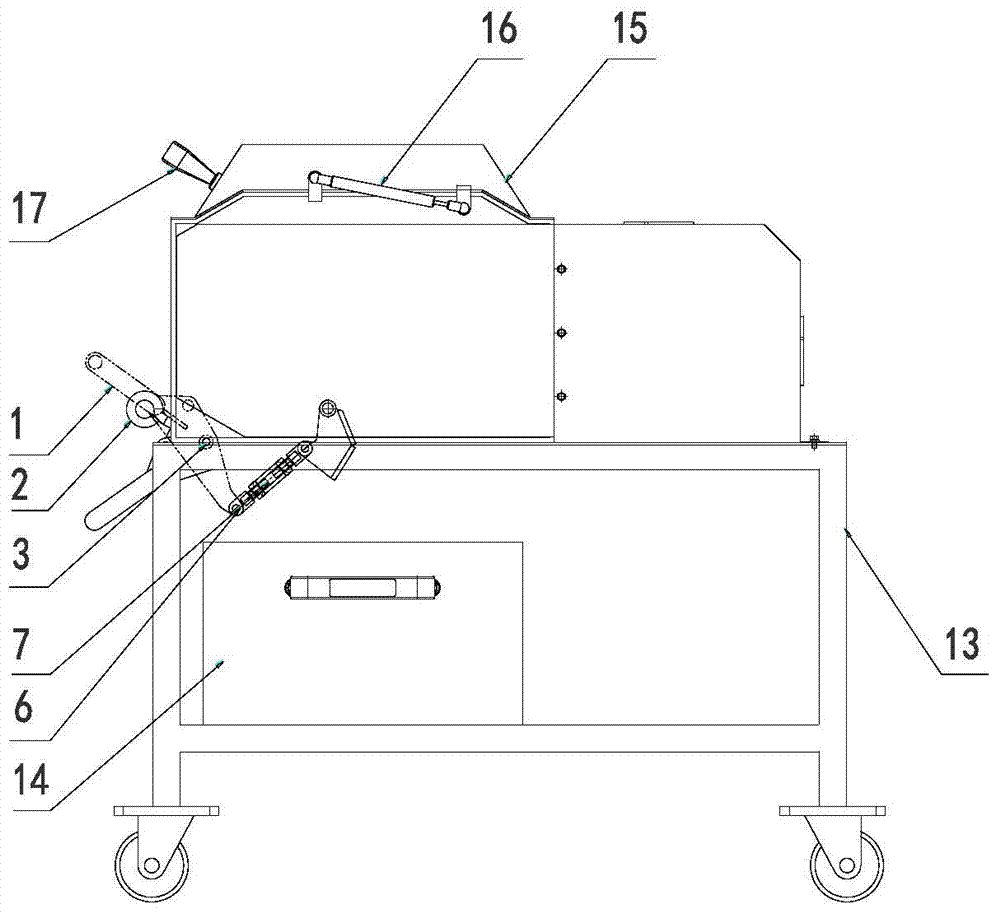

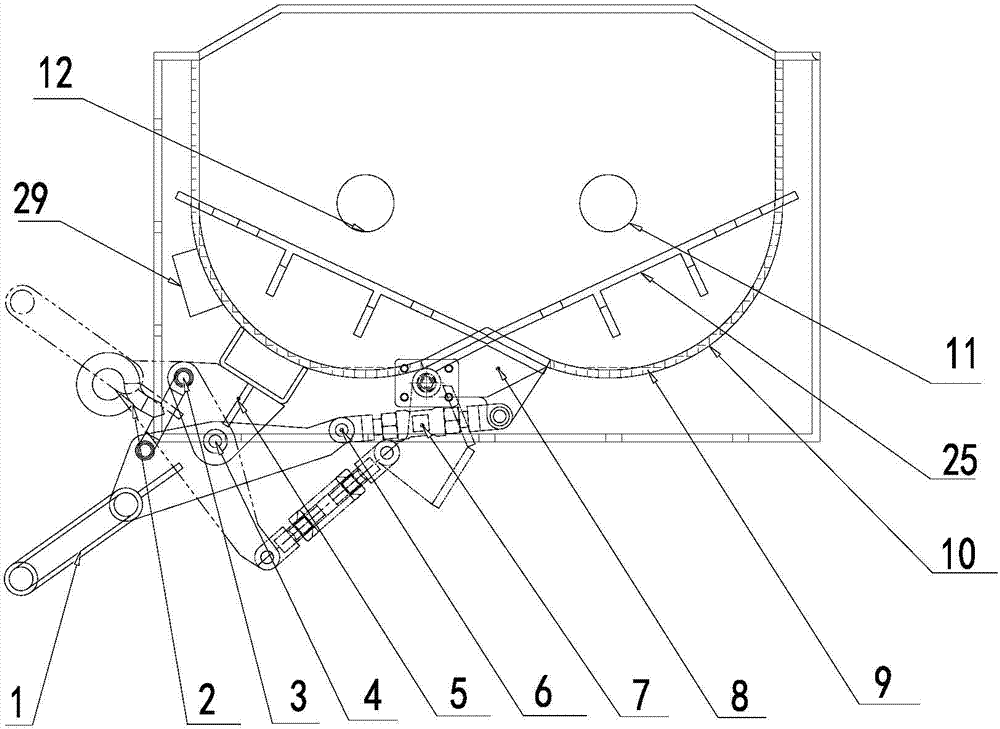

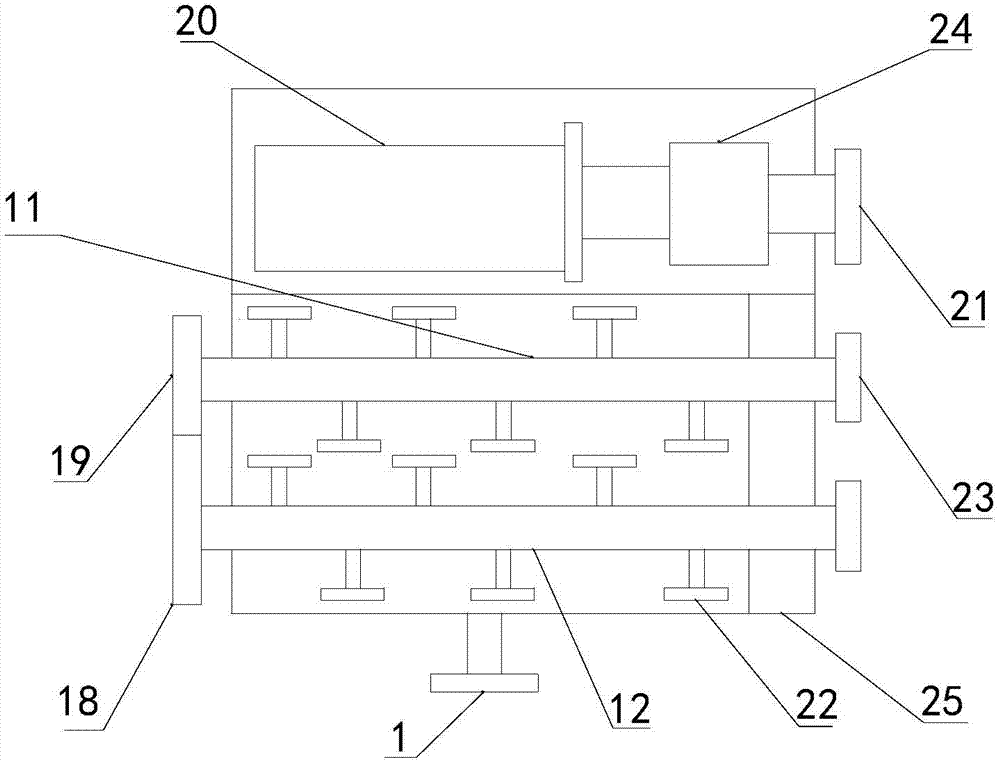

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] see Figure 1-6 , the present invention includes a heat preservation heating device, a discharge device and a mixing tank 10 with a motor 20 fixed on the outside; a speed reducer 24 is fixed on the output shaft of the motor 20, and a driving gear 21 is fixed on the speed reducer 24, and the driving gear 21 passes through a belt Connect with the first driven gear 23, and the first driven gear 23 is fixed on one end of the first stirring shaft 11 in the mixing cylinder 10, and the other end of the first stirring shaft 11 is fixed with the second synchronous gear 19; 10 is also provided with the second stirring shaft 12 parallel to the first stirring shaft 11; and one end of the second stirring shaft 12 is provided with a synchronous gear 18 meshed with the second synchronous gear 19; A plurality of blades are arranged on the shaft 12; the thermal insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com