Injection fragmentation device and injection fragmentation method

A crushing method and crusher technology, applied in the fields of jet crushing and jet crushing, can solve problems such as increased viscosity of mash, reduction of water absorption speed of crushed raw material particles, rapid crushing, dissolution and liquefaction of hard-to-large starch particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

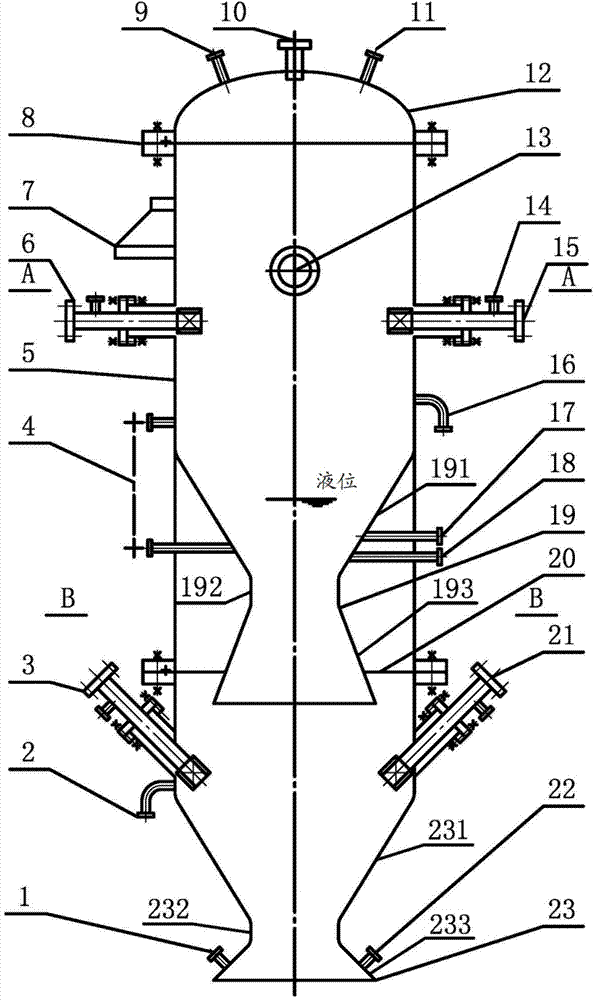

[0039] The jet breaker of the present invention will now be described with reference to the accompanying drawings.

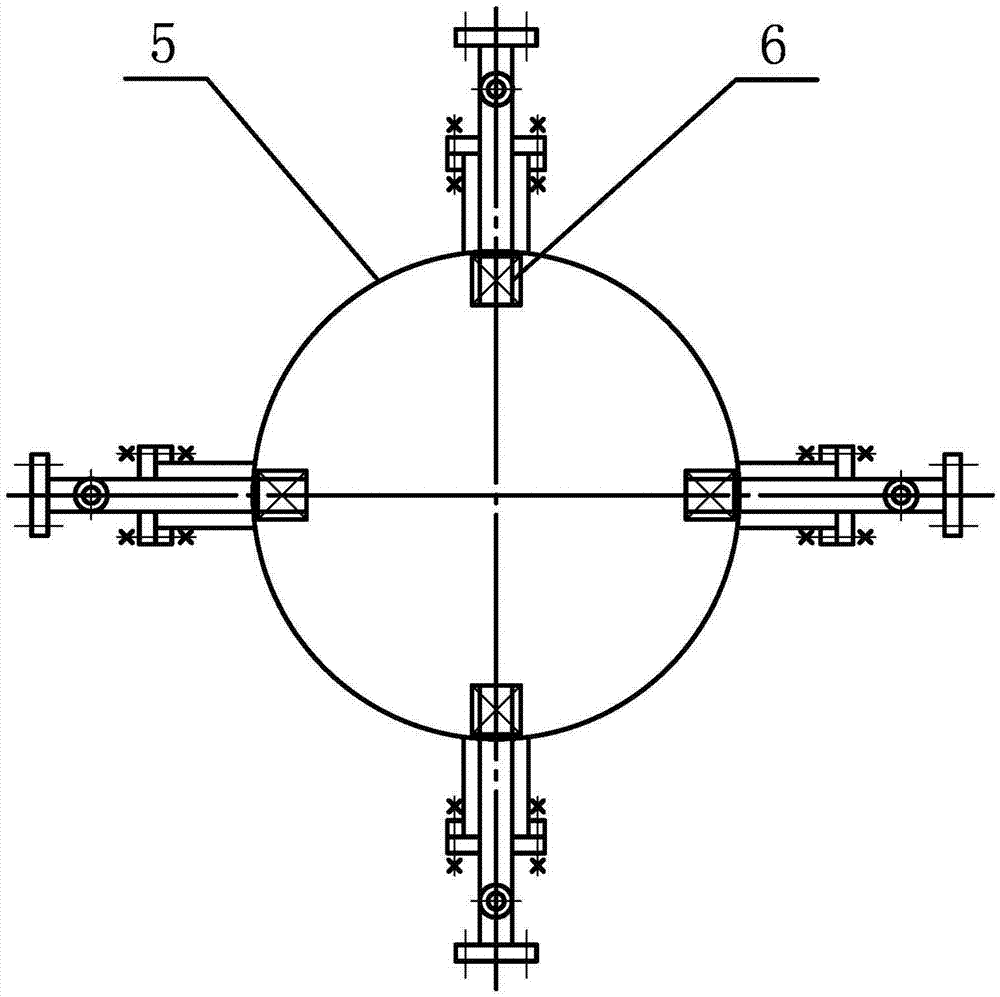

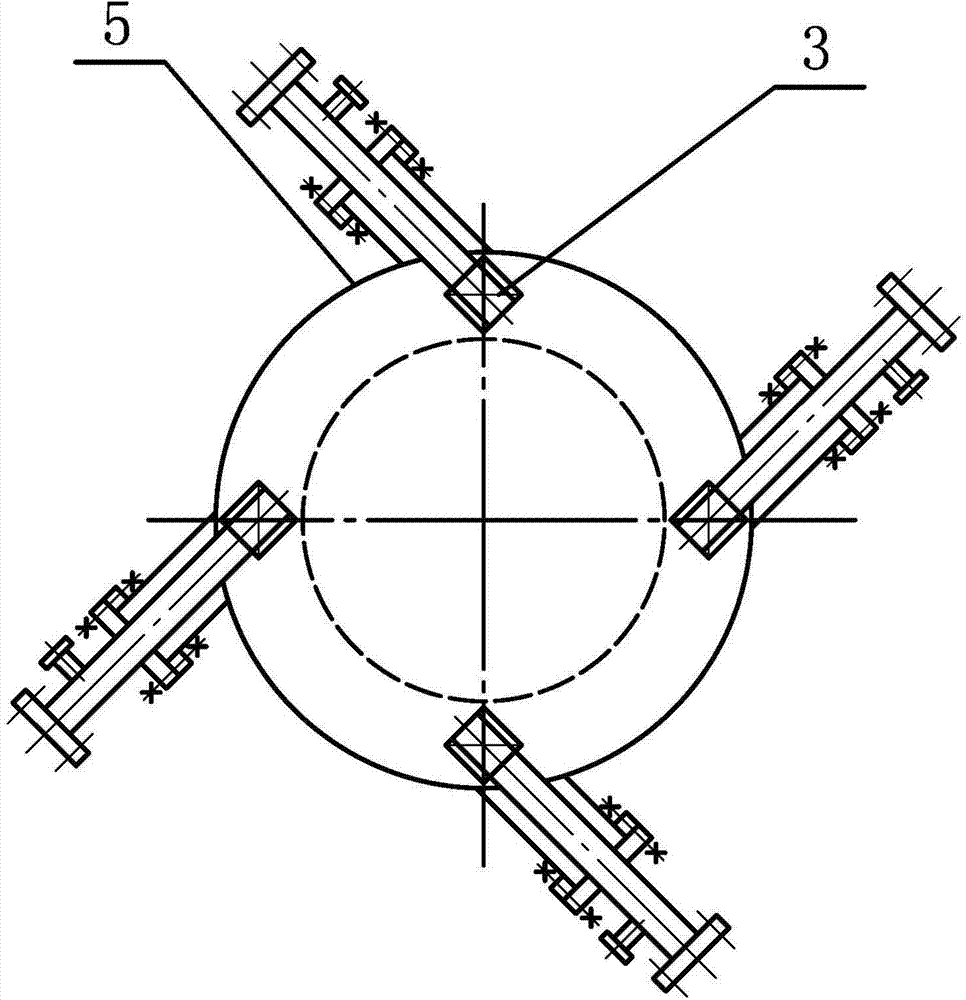

[0040] Such as figure 1 Shown is a schematic structural view of the jet breaker of the present invention, which includes a housing 5 , a primary nozzle 6 , a secondary nozzle 3 , a primary shrinking and expanding channel 19 and a secondary shrinking and expanding channel 23 . Wherein, the first-stage nozzle 6 and the second-stage nozzle 3 are respectively arranged around the outer peripheral wall of the housing 5, and both spray towards the inside of the housing 5, and the first-stage shrinking and expanding channel 19 is arranged on the inner peripheral wall of the housing 5, and its installation position It is located between the first-stage nozzle 6 and the second-stage nozzle 3 , while the second-stage narrowing and expanding passage 23 is disposed at the bottom of the casing 5 , that is, the second-stage shrinking and expanding passage 23 is formed as the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com