A kind of composite iron ore sorting method

A compound iron ore and ore grinding technology, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of low screening efficiency, difficult improvement, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

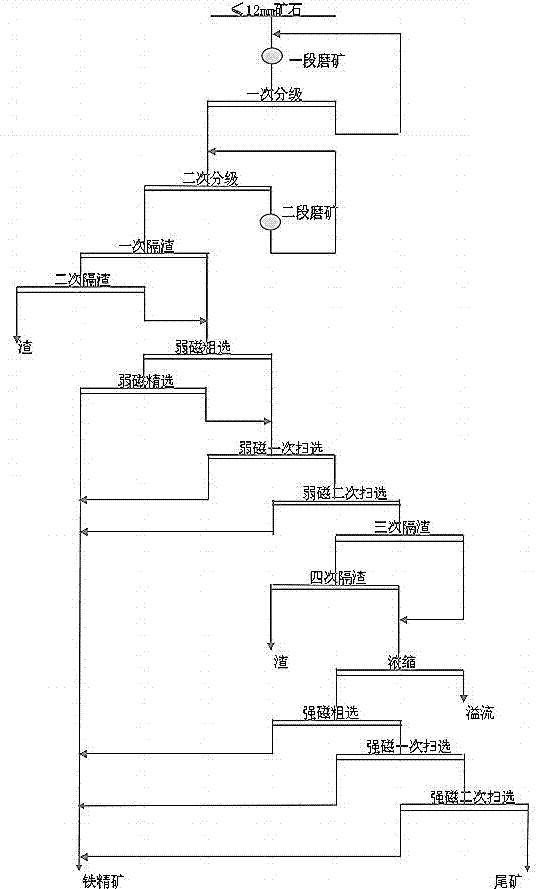

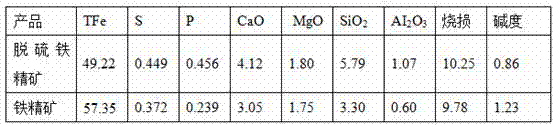

[0033] Please see figure 1 , figure 1 It is a process flow diagram of a compound iron ore separation method, which adopts two-stage closed-circuit grinding and classification, two slag separations, weak magnetic roughing, weak magnetic separation, weak magnetic two sweeps, two slag separations, and concentration , strong magnetic roughing, and strong magnetic twice-sweeping, when the ore particle size is less than 12mm, the ore iron grade is 49%, of which the magnetic iron grade is 29%, the hematite iron grade is 8%, the siderite iron grade is 11%, Sulfur grade 0.47%, phosphorus grade 0.5%, SiO 2 When the grade is 6%, the grinding concentration of the first stage is 75%, the steel ball filling rate is 38%, the sand return ratio of the primary spiral classifier is 80%, the overflow concentration of the primary spiral classifier is 55%, and the overflow particle size of the primary spiral classifier is less than 200 mesh. 45%; second stage grinding concentration 70%, steel ball ...

Embodiment 2

[0036] Please see figure 1 , figure 1 It is a process flow diagram of a compound iron ore separation method, which adopts two-stage closed-circuit grinding and classification, two slag separations, weak magnetic roughing, weak magnetic separation, weak magnetic two sweeps, two slag separations, and concentration , strong magnetic roughing, and strong magnetic twice-sweeping, when the ore particle size is less than 12mm, the ore iron grade is 51%, of which the magnetic iron grade is 30%, the hematite iron grade is 7%, and the siderite iron grade is 10%. Sulfur grade 0.45%, phosphorus grade 0.4%, SiO 2 When the grade is 5%, the grinding concentration of the first stage is 80%, the steel ball filling rate is 38%, the sand return ratio of the primary spiral classifier is 100%, the overflow concentration of the primary spiral classifier is 60%, and the overflow particle size of the primary spiral classifier is less than 200 mesh. 40%; second stage grinding concentration 75%, stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com