Machining device for curvature radius-adjustable aspheric concave lens

A technology of curvature radius and processing device, applied in metal processing equipment, grinding drive device, manufacturing tool, etc., to achieve the effect of strong practicability, high processing efficiency and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

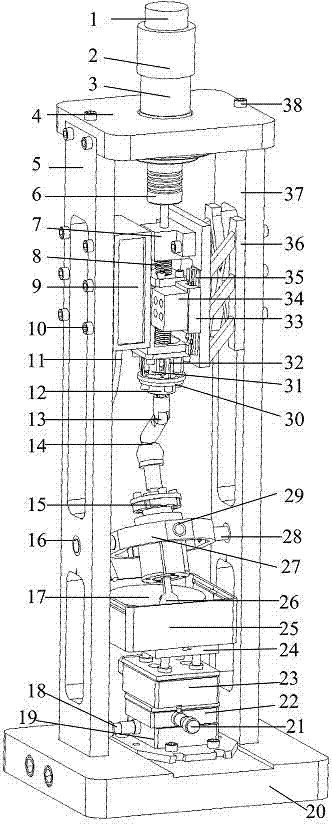

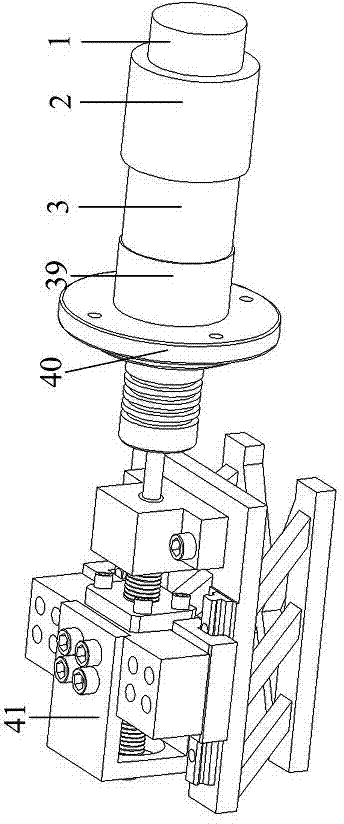

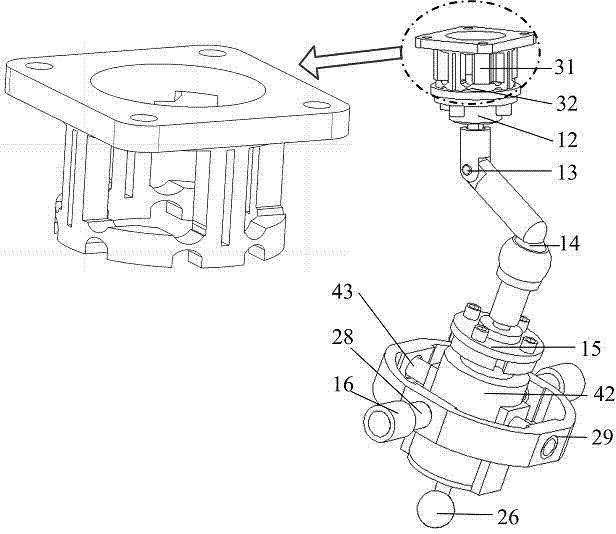

[0039] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0040] see Figure 1 to Figure 9 As shown, the adjustable radius of curvature aspheric concave lens processing device of the present invention includes a macro-micro feed unit, a revolution motion unit, an autorotation motion unit, a lens installation and adjustment unit, a cooling unit, and a supporting base unit, wherein the macro-micro feed The feed motor flange 40 and feed support frame 36 in the unit are rigidly connected with the upper mounting plate 4 and the right side vertical plate 37 in the support base unit respectively, and the directional revolution rotary joint 13 and directional swing in the revolution motion unit The joint 14 is rigidly connected with the flexible teaching hinge 32 in the macro and micro feed unit and the autorotation motor 42 in the autorotation motion unit through the revolution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com