Water-based flame retardant liquid for historic building and preparation method of water-based flame retardant

A flame retardant liquid, water-based technology, applied in the field of water-based flame retardant liquid for ancient buildings and its preparation, can solve the problems of difficulty in maintaining the original appearance, a large number of toxic and harmful substances, and unsatisfactory flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

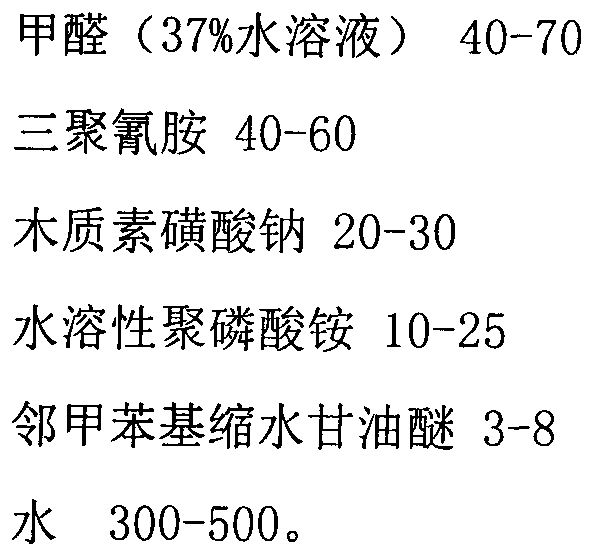

[0024] Example 1 Table 1 Flame Retardant Liquid Formula (Kg)

[0025] components

[0026] According to the weight in Table 1, add formaldehyde into the reaction kettle, adjust the pH value to 7.5 with triethanolamine, add melamine while stirring, raise the temperature to 60°C, and react for 2 hours. When the solution becomes clear and transparent, cool to room temperature and add Water, sodium lignosulfonate, water-soluble ammonium polyphosphate, and o-cresyl glycidyl ether are stirred evenly, and finally the pH value of the solution system is adjusted to 6.5 with triethanolamine, and a colorless, odorless, impurity-free, uniform transparent liquid is obtained.

Embodiment 2

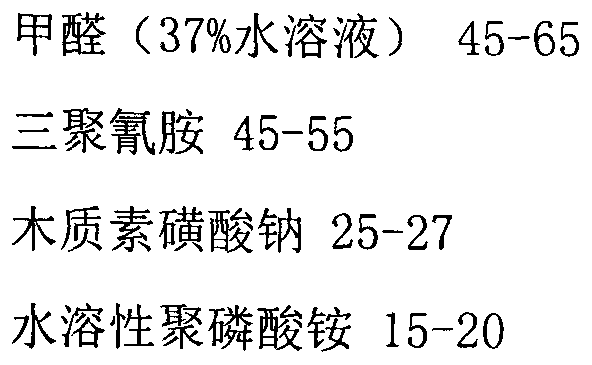

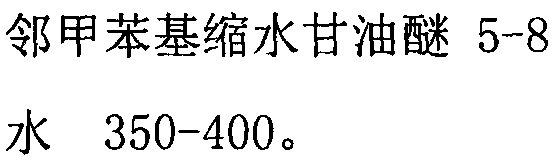

[0027] Example 2 Table 2 Flame Retardant Liquid Formula (Kg)

[0028] components

[0029] water

[0030] According to the weight in Table 2, add formaldehyde into the reaction kettle, adjust the pH value to 7.5 with triethanolamine, add melamine while stirring, heat up to 65°C, react for 2 hours, when the solution becomes clear and transparent, cool to room temperature, add water , sodium lignosulfonate, water-soluble ammonium polyphosphate, o-cresyl glycidyl ether, and stir evenly, and finally adjust the pH value of the solution system to 7.2 with triethanolamine, and obtain a colorless, odorless, impurity-free, uniform transparent liquid.

Embodiment 3

[0031] Example 3 Table 3 Flame Retardant Liquid Formula (Kg)

[0032] components

[0033] According to the weight in Table 3, add formaldehyde into the reaction kettle, adjust the pH value to 7.8 with triethanolamine, add melamine while stirring, raise the temperature to 70°C, and react for 2 hours. When the solution becomes clear and transparent, cool to room temperature and add Water, sodium lignosulfonate, water-soluble ammonium polyphosphate, and o-cresyl glycidyl ether are stirred evenly, and finally the pH value of the solution system is adjusted to 7.0 with triethanolamine to obtain a colorless, odorless, impurity-free, uniform and transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com