Intelligent self-detection brake for traction machine

A mechanical brake and self-inspection technology, which is applied in hoisting devices and other directions, can solve the problems of complex installation, accelerated friction plate damage, and fast friction plate damage, and achieves the effects of firm connection, increased mutual friction, and reduced wear speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

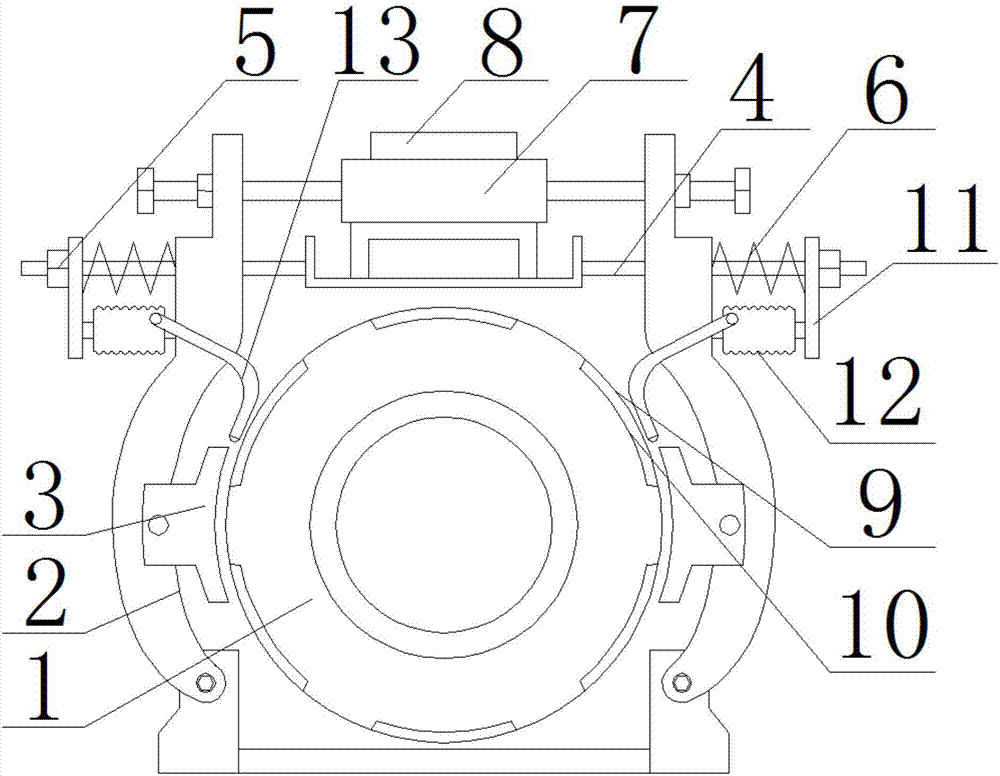

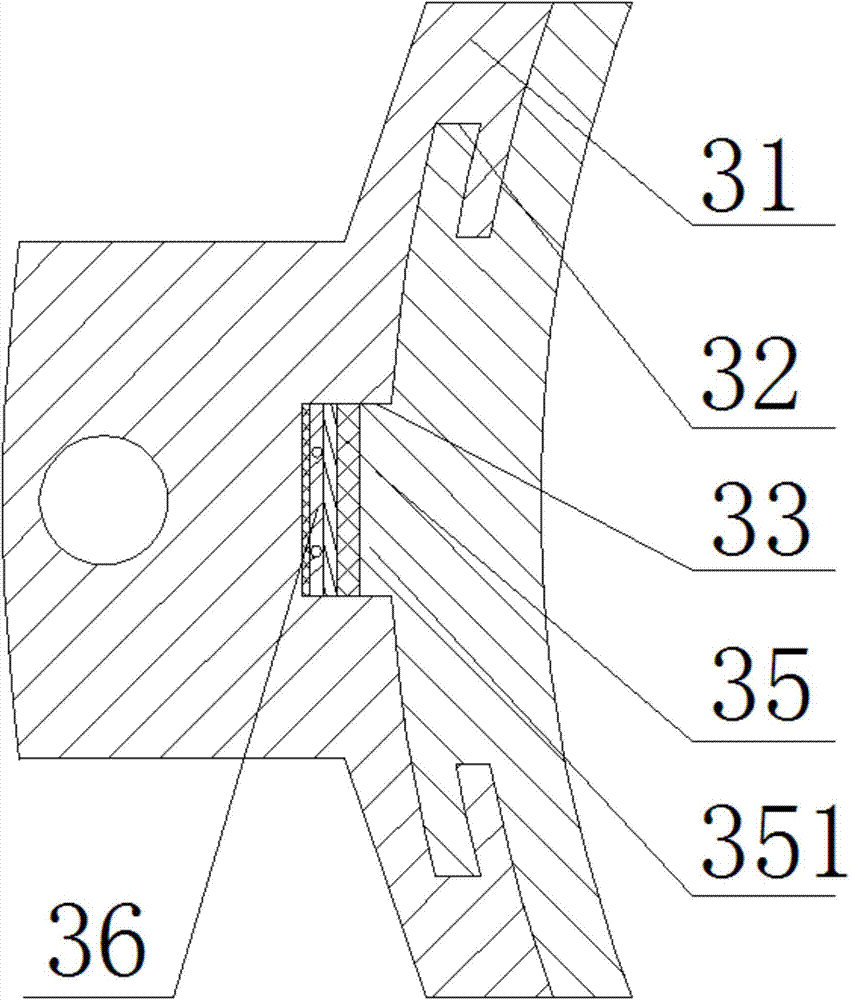

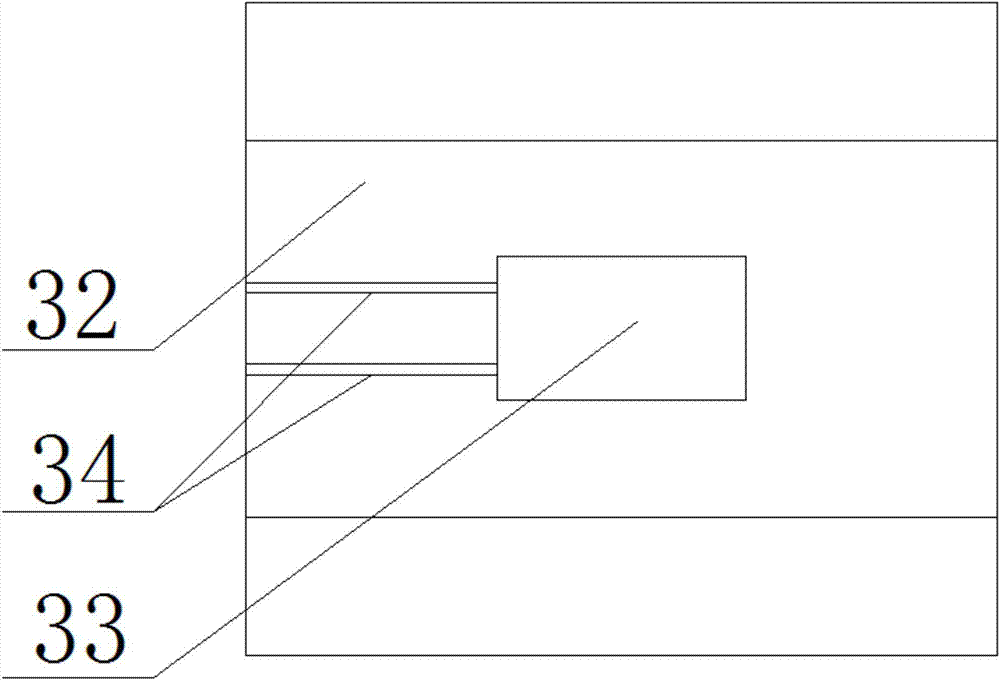

[0014] Embodiment of the present invention: an intelligent self-detection traction machine brake, as attached Figure 1-3 As shown, it includes a brake wheel 1 located at the head end of the traction machine housing, and a brake arm 2 is provided on both sides of the brake wheel 1, and the lower end of the brake arm 2 is installed on the base of the traction machine. Each brake arm 2 is connected with a brake shoe assembly 3, and the upper end of each brake arm 2 is penetrated with a brake lever 4, and the head end of the brake lever 4 is provided with an adjusting nut 5, and the adjusting nut 5 is connected to the A brake spring 6 is arranged on the shaft between the brake arms 2, a magnet 7 is arranged above the brake wheel 1, and the magnet 7 is installed on the base of the magnet, and the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com