Vortex vertical oil-water separation equipment

An oil-water separation and vortex technology, which is applied in liquid separation, separation methods, water pollutants, etc., can solve the problems of poor market economy and large land occupation, and achieve the effect of reducing traction force, improving difficulty, and good oil-water separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

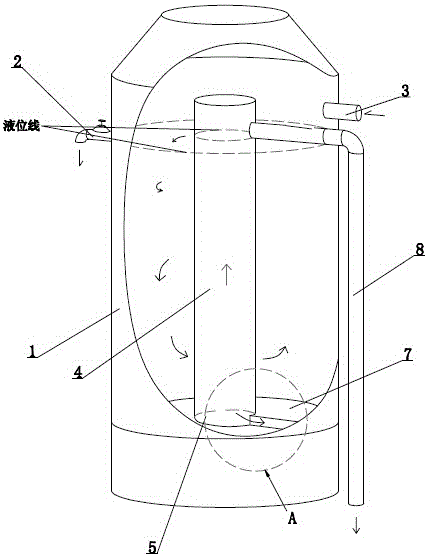

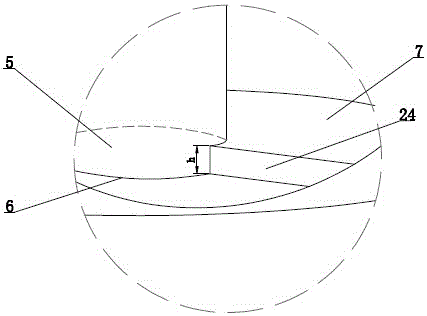

[0036] Such as figure 1 with figure 2 As shown, a vortex type vertical oil-water separation device provided in this embodiment includes a cylinder body 1, and an oil discharge nozzle 2 and a water inlet nozzle 3 are arranged on the cylinder wall of the cylinder body 1, wherein the discharge pipe The height of the oil pipe port 2 on the cylinder wall is consistent with the liquid level line in the cylinder body 1, the water inlet pipe port 3 is higher than the oil discharge pipe port 2, the cylinder body 1 is a vertical structure, and the water inlet pipe port The pipe axis of 3 is in the tangential direction of the cylinder 1, and a standpipe 4 is added in the cylinder 1. The lower nozzle 5 of the vertical pipe 4 is located at the bottom of the cylinder 1, and its nozzle is spiral along 6. structure, there is a height difference h between the starting point and the end point of the helix in the vertical direction, and a water blocking plate 7 is distributed along the above-m...

Embodiment 2

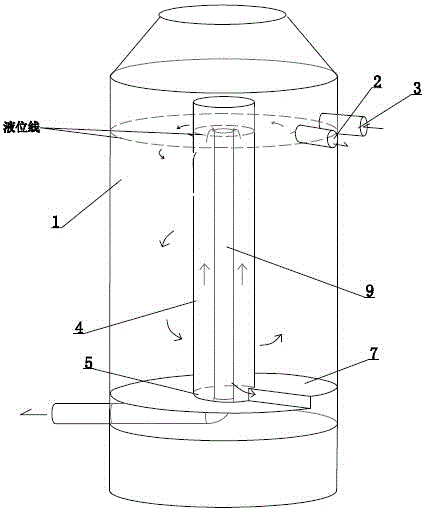

[0039] A kind of vortex type vertical oil-water separation equipment provided in this embodiment, its general structure is consistent with embodiment 1, as image 3 As shown, but the water outlet and drainage mechanism in this embodiment is the second water outlet and drainage pipe 9, the end of one side of the second water outlet and drainage pipe 9 is sealed and runs through the cylinder wall of the cylinder body 1, and from the above-mentioned vertical pipe 4 The lower nozzle 5 extends into the standpipe 4 .

Embodiment 3

[0041] The general structure of the vortex type vertical oil-water separation equipment provided in this embodiment is consistent with that of Embodiment 2, but in order to be able to remove the grease particles, even the oil-water emulsion free in the water body, by mechanical means lifted to the surface of a body of water, such as Figure 4 As shown, the outer pipe wall of the standpipe 4 in this embodiment is distributed with a plurality of splitter blades 10 according to the spiral structure, and the direction of the helix is the same as entering the cylinder 1 through the water inlet 3 above, and then along the cylinder. The water flow direction of the vortex formed on the inner surface of the cylinder wall of the body 1 is opposite, and the specification and height design of the above-mentioned splitter blades 10 are related to the critical point of the buoyancy of the grease particles and the water flow traction force; wherein, each of the above-mentioned splitter blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com