One-off absorbing product

An absorbent article, a disposable technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of generating a large amount of dust, large rewet volume of products, and high price, so as to improve absorption efficiency, large diffusion area, and rapid penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

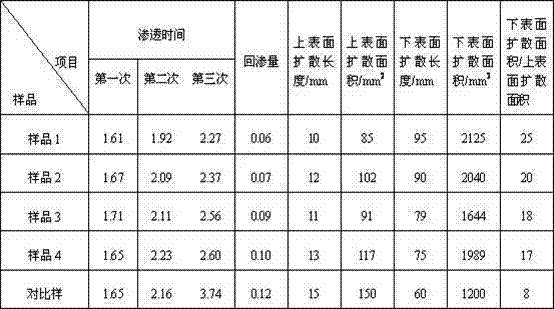

Examples

Embodiment Construction

[0011] A disposable absorbent article includes a hydrophilic surface layer material, a core layer material, a bottom layer impermeable material, and a multi-layer composite flow-guiding material located between the hydrophilic surface layer material and the core layer material. The flow guiding material is composed of two layers of fiber webs, the upper fiber web is bonded and reinforced by hot air, and the lower fiber web is reinforced by water jet entanglement.

[0012] The surface fiber net is made of skin-core bicomponent fibers, in which the skin layer is polyethylene, the core layer is polyester, the fiber length is 30~70mm, and the fineness is 3~40D. / HA-YJ-1308 (commercially available) treatment. The surface fibers are combed by the cylinder and then transferred to the doffer. By reducing the speed ratio between the doffer and the agglomeration roller, most of the fibers after carding are arranged regularly in the length direction. After the fiber web is formed, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com