Assembled balcony

A prefabricated and balcony technology, which is applied in the direction of architecture and building construction, can solve the problems of difficulty between balconies, inconvenient hoisting and assembly, and slow construction speed, so as to shorten the construction period, improve construction efficiency, and improve Anti-bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

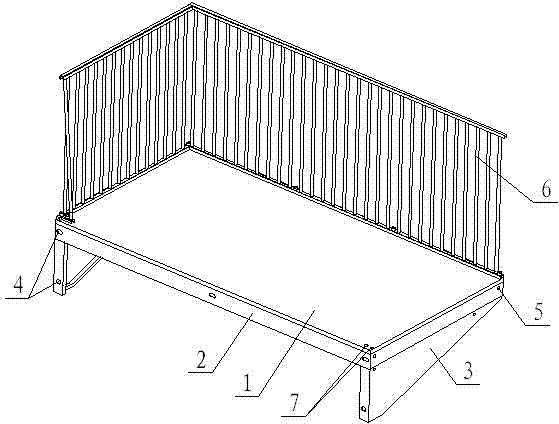

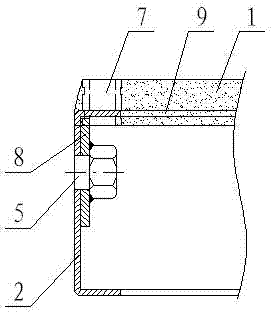

[0019] Such as figure 1 , figure 2 , image 3 As shown, a prefabricated balcony includes a balcony plate and a support plate 3 connected to the bottom of the balcony plate. The balcony slab is composed of two layers of concrete panel 1 and steel frame 2. The concrete panel 1 is embedded with steel mesh 9. The upper part of the steel frame 2 is prefabricated in the concrete panel 1 and connected with the embedded steel mesh 9.

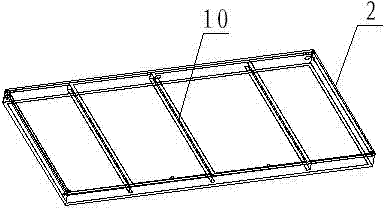

[0020] The steel frame 2 is made of section steel, and is a rectangular steel frame 2 with an intermediate steel beam 10 , which is wholly or partly prefabricated in the concrete panel 1 . The rectangular steel frame 2 surrounds the concrete panel 1 from all sides, forming a wrapping shape. This steel frame 2 wraps the edges, is embedded in the concrete panel 1 and is connected with the steel mesh 9, so that the concrete panel 1 and the steel frame 2 form a structurally strong force-bearing whole, which greatly reduces the amount of concrete and imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com