Spiral unearthed following jacking pipe curtain machine

A pipe curtain and jacking technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of inability to correct deviation in time during the jacking process and the construction speed of the pipe curtain machine is slow, so as to improve the jacking effect and improve the jacking effect. Accuracy and improved ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

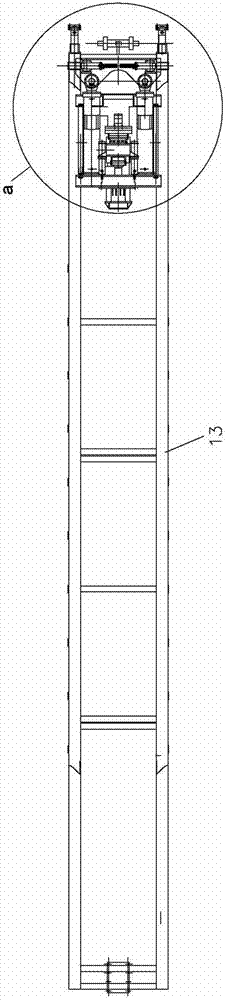

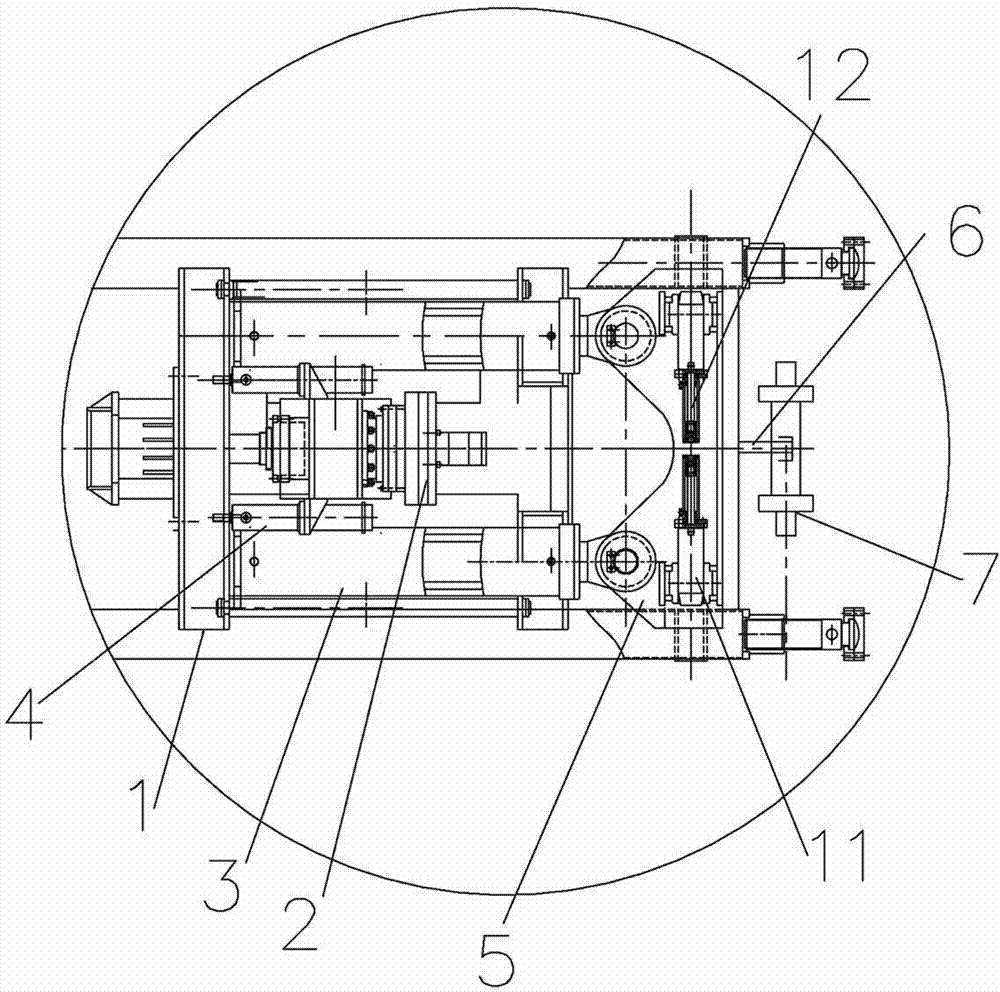

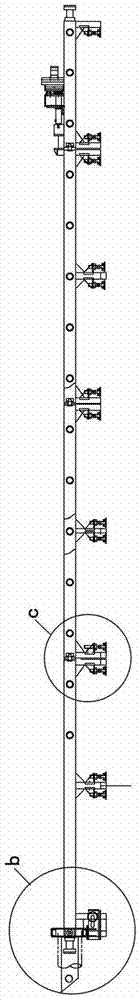

[0038] see Figure 1-9 , a spiral excavation and pipe jacking pipe curtain machine, including a frame, a pipe curtain drilling machine 20 installed on the frame, and a deviation correction system; the frame includes a guide rail 13, and the guide rail is provided with a positioning hole 15 , the pipe curtain drilling machine is connected with the auger rod 16; the pipe curtain drilling machine 20 includes:

[0039] The power head 2 is driven by the background power station, and is used to drive the auger drill pipe to rotate and drill; the power head is connected to the back of the push plate 1 that pushes the pipe screen steel pipe through the power head adjustment cylinder connection 4, and the The rear of the push plate 1 is provided with a push cylinder 3 and a push cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com