Alternate one-way valve and pressurization system

A technology of alternating one-way valve and booster system, which is used in fluid pressure actuation system testing, multi-way valve, control valve and other directions, can solve the problems of prolonged filling time, low test efficiency, overpressure, etc., and achieve stable The effect of supercharging and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

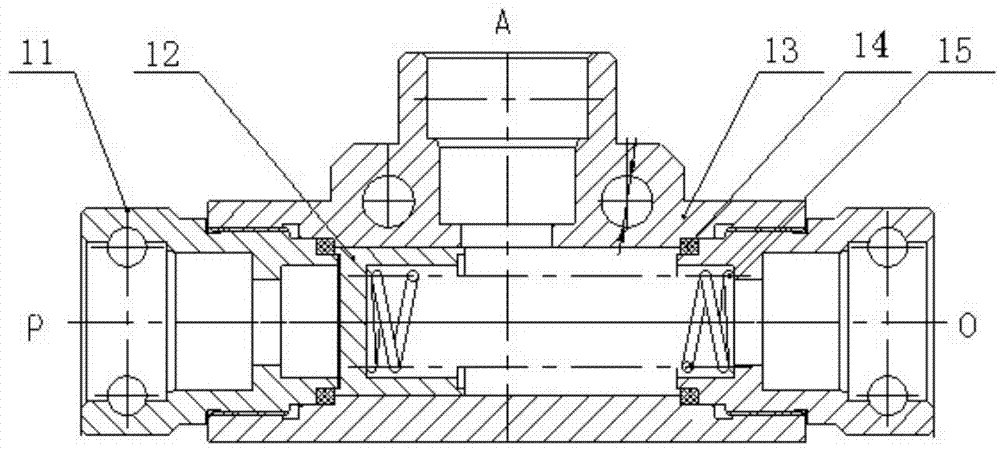

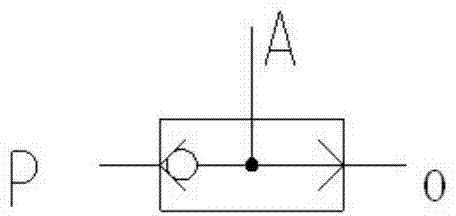

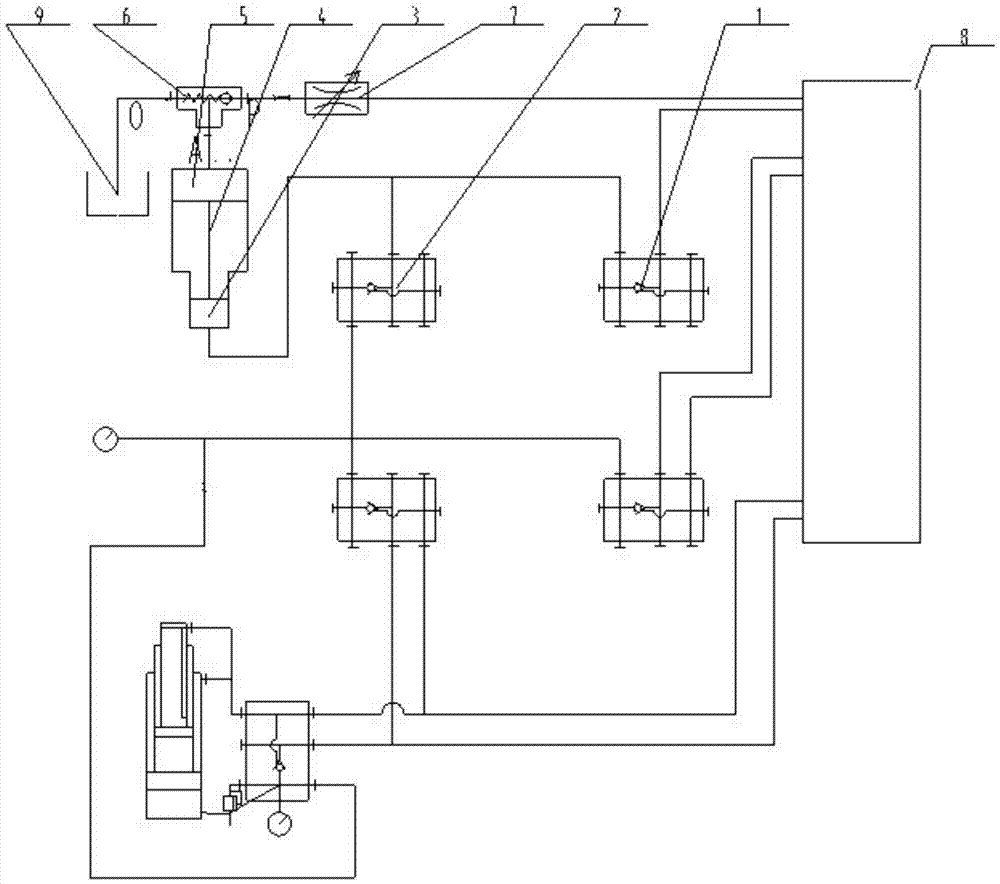

[0025] Such as image 3 As shown, just look at the group of electromagnetic reversing valves for liquid filling / boosting.

[0026] The working principle is as follows: ① When the liquid is filled, the emulsion from the electromagnetic reversing valve enters the small chamber of the supercharger through two one-way valves, and then pushes the piston rod to compress the large chamber, so that the emulsified liquid in the large chamber of the supercharger The liquid flows into the liquid return tank through the working port and liquid return port of the alternate one-way valve, and the liquid inlet port is blocked. Since the emulsion flowing out of the large chamber of the supercharger does not pass through the throttling plug and the electromagnetic reversing valve group, but directly returns to the liquid return system, the filling time is shortened and the test efficiency is improved. ② During the pressurization action, the emulsion from the electromagnetic reversing valve (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com