Double-layer active-passive electromechanical integrated type vibration isolation device

An integrated and motivated technology, applied in mechanical equipment, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of height increase, low control accuracy, air tightness and gas force lag, etc. The effect of low energy consumption, increased smoothness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

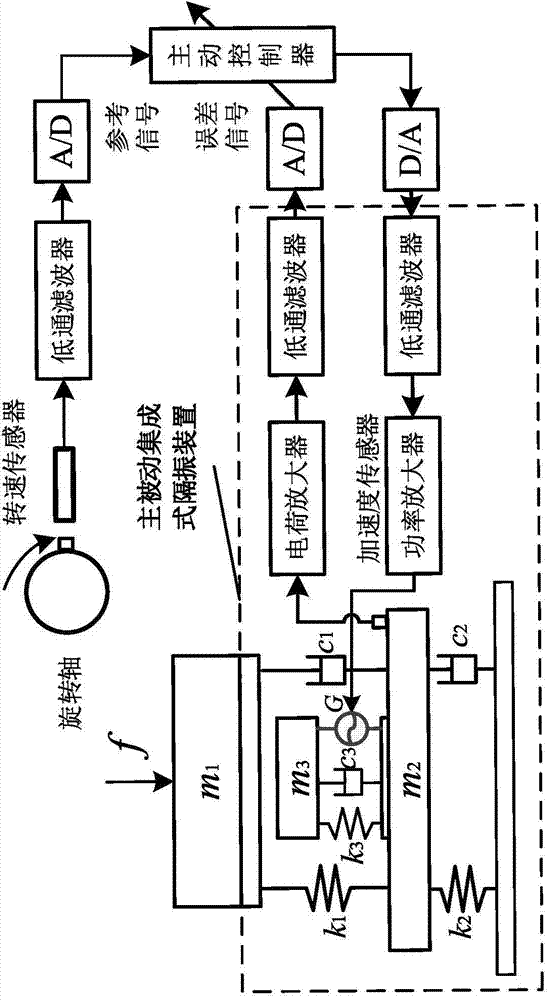

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

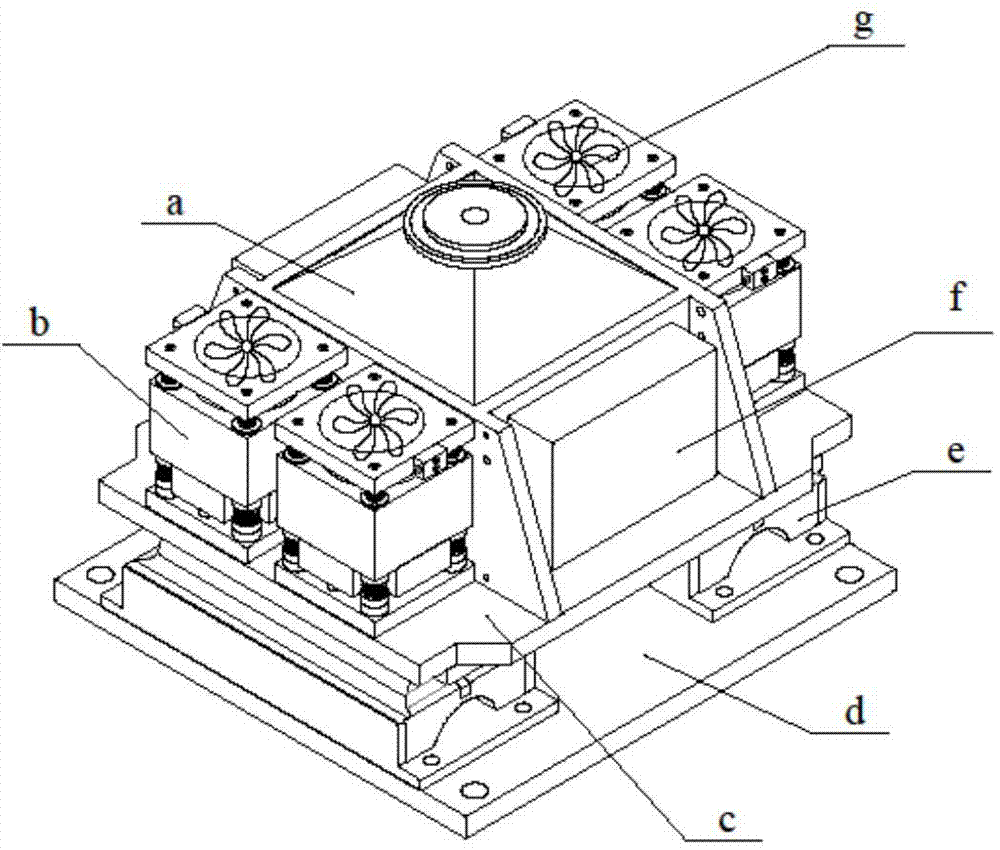

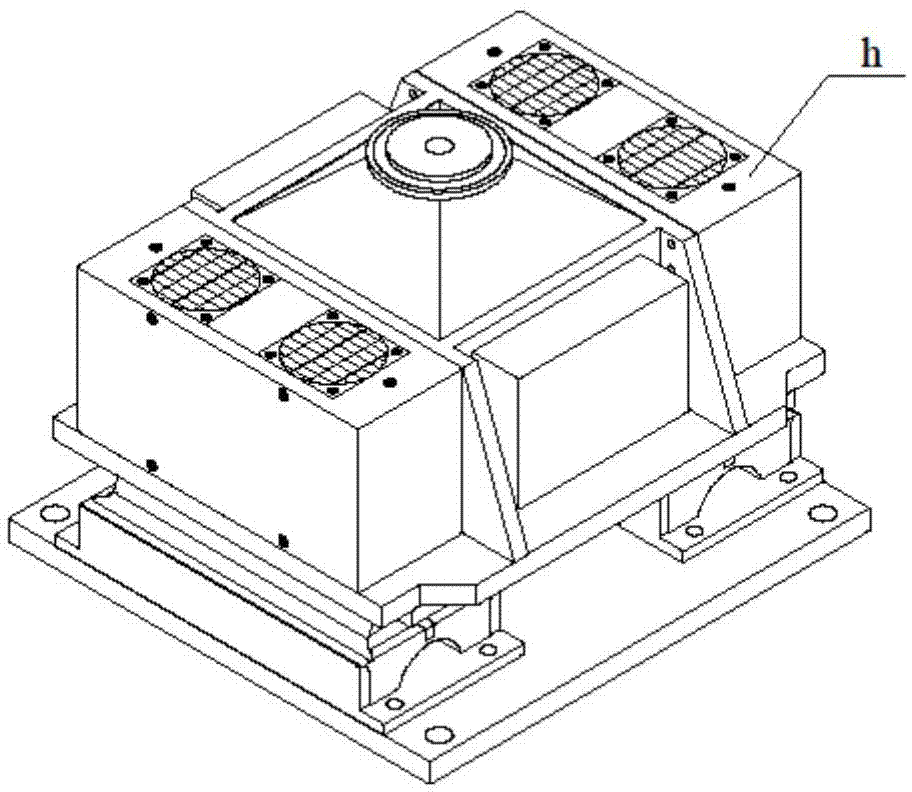

[0028] combine Figure 2-Figure 3 , the double-layer main-passive electromechanical integrated vibration isolation device based on the four-axis inertial electromagnetic exciter includes the passive upper rubber vibration isolator a, four four-axis inertial electromagnetic exciters b, the middle frame structure c, the integrated The control signal conditioning device and the acceleration signal conditioning device f. Among them, four four-axis inertial electromagnetic exciters b are symmetrically arranged on the left and right sides of the middle frame structure c as active actuators, and the integrated control signal conditioning equipment and acceleration signal conditioning equipment f are symmetrically arranged on the front and rear recesses of the middle frame structure c. In the groove, an acceleration sensor is integrated on the middle fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com