Weighing apparatus measurement testing simulation weight loading device

A technology of measurement testing and loading device, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of cumbersome operation, long working time, indicating value error, etc., and achieve the effect of reducing operating procedures, flexible use and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

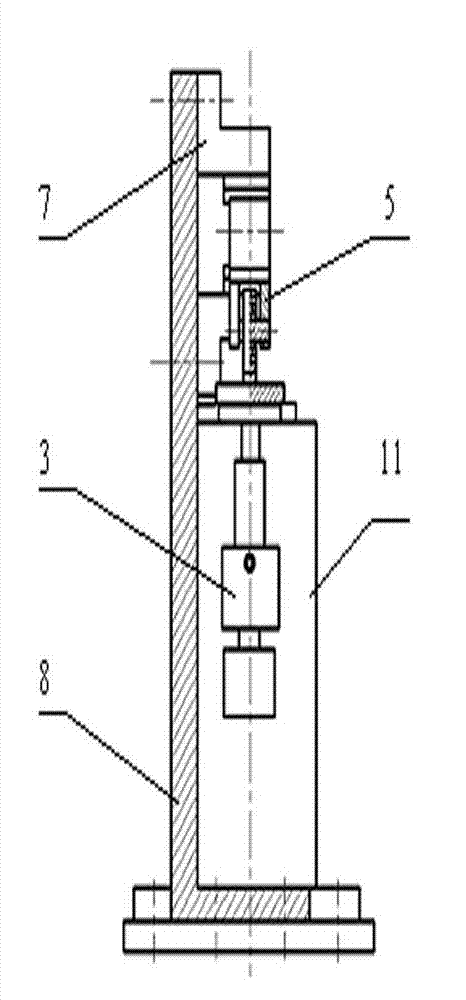

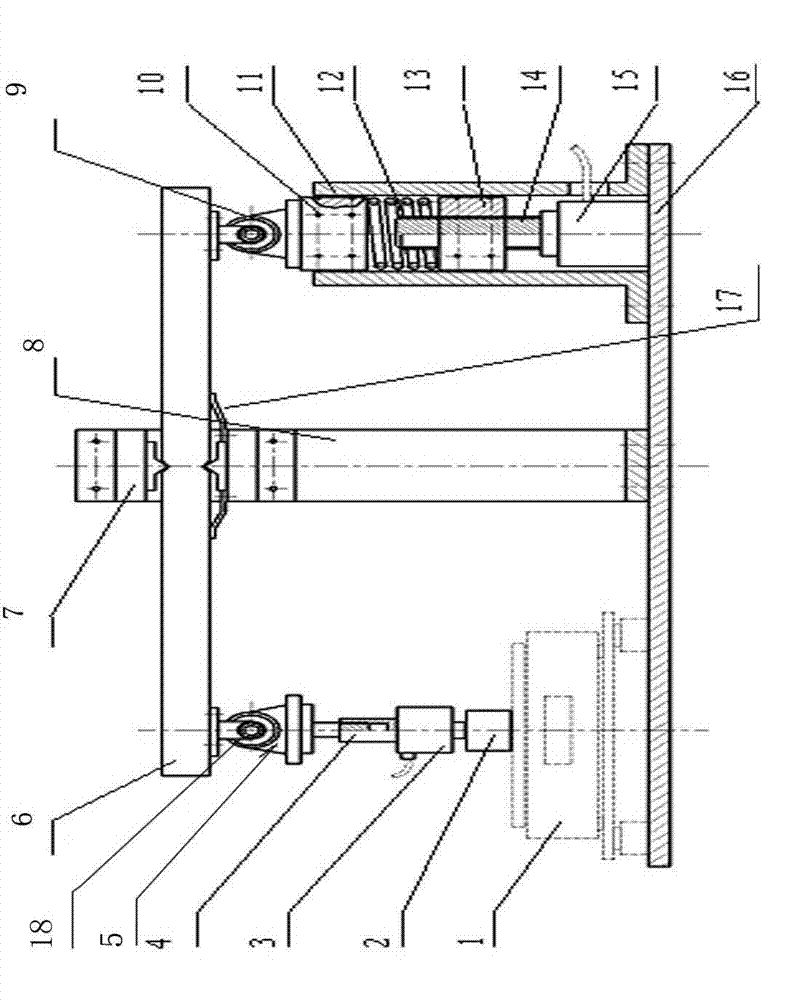

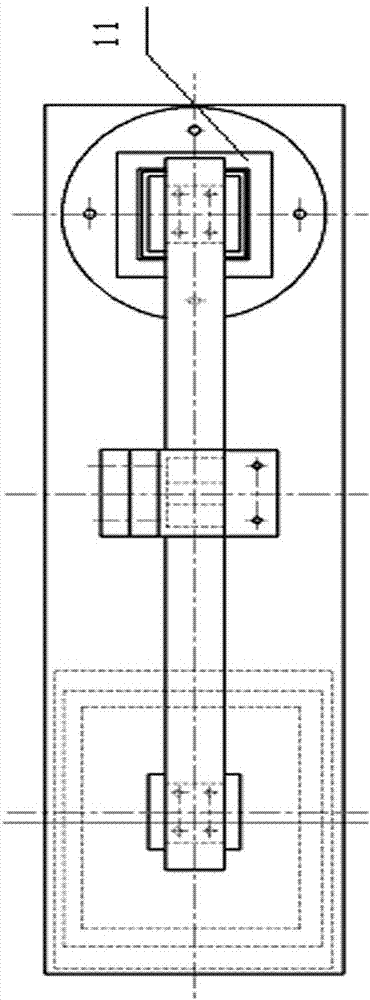

[0023] The weighing apparatus measurement test simulation weight loading device of the present invention is composed of the tested equipment placed on the base, a height-adjustable support base, a simulation weight, a high-precision force sensor, a height adjustment connecting rod, a gravity self-adjusting verticality bearing seat, a force transmission It is composed of lever, upper and lower blades and supporting body, structural support, bearing seat under force, square ball slider, square cylinder, spring, square sliding nut, lead screw, stepping motor, device base, and reset balance spring piece.

[0024] Since the device adopts the principle of mechanical lever, spring principle, sliding pair, gravity horizontal joint, force sensor and stepping motor control principle, an effective structure is designed, which has the ability to convert the fine-tuning step displacement into continuous force, The force is loaded and measured, and fed back to the computer, so as to further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com