Infrared continuous fire source monitoring method and infrared continuous fire source monitoring system

A fire source and infrared technology, applied in the direction of electric radiation detectors, etc., can solve the problems of reducing maintenance costs, image interruption, and many mechanical failures of equipment, so as to improve production efficiency, improve stability, and reduce production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

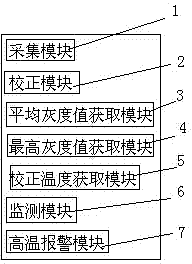

[0025] The specific embodiment of the present invention is: provide a kind of infrared continuous fire source monitoring method, comprise the infrared focal plane sensor array that is made up of infrared focal plane sensor, optical mechanism, described infrared continuous fire source monitoring method comprises the following steps:

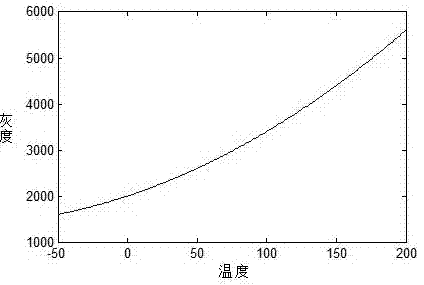

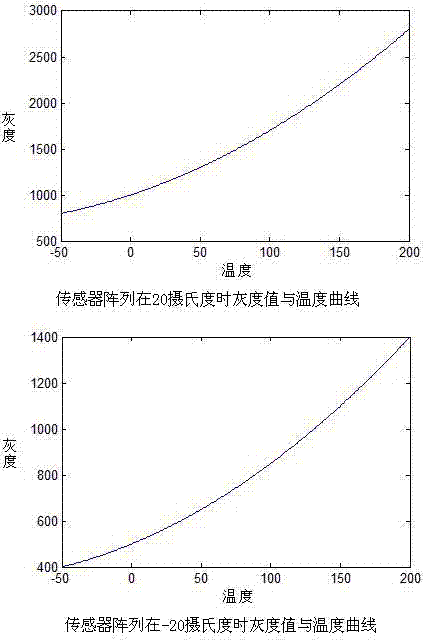

[0026] Pre-stored gray-scale images: Pre-store gray-scale images of multiple objects with uniform temperature under different working temperature conditions of the infrared focal plane sensor array.

[0027] The specific implementation process is: pre-acquisition of multiple gray-scale images of objects with uniform temperature under different working temperature conditions of the infrared focal plane sensor array, and then pre-store them. Each sensor unit of the infrared focal plane sensor array corresponds to a pixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com