Automatic testing system and method for power management product based on Labview

A technology of automated testing and power management, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as click errors, slow speed, manual judgment errors, etc., and achieve the effect of reducing the risk of outflow of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

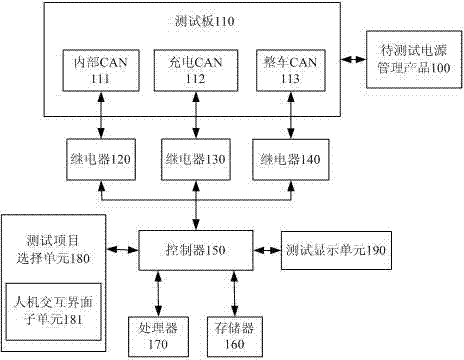

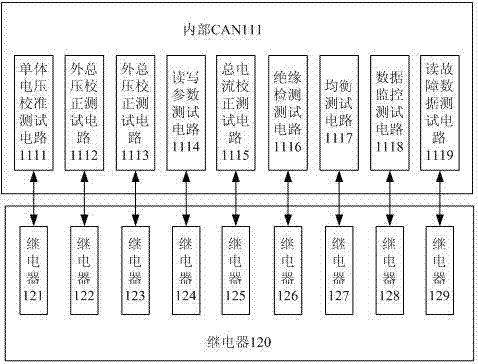

[0026] Such as figure 1 As described, a Labview-based automated test system for power management products provided by the present invention includes: a test board 110, a relay 120, a relay 130, a relay 140, a controller 150, a memory 160, a processor 170, and a test item selection unit 180, The test board 110 includes an internal CAN circuit 111, a charging CAN circuit 112 and a vehicle CAN circuit 113, the internal CAN circuit 111 is a connecting circuit for completing the test function, and the charging CAN circuit 112 is an external power supply for the The charging circuit for charging the power management product 100 to be tested, the vehicle CAN circuit 113 is a control circuit for the entire electric vehicle system to control the power management product 100 to be tested, and the controller 150 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com