Die for high-strength ratchet shaft machining, and machining process thereof

A ratchet shaft and high-strength technology, applied in the field of mechanical processing, can solve problems such as refractory impurities in the injected material and affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

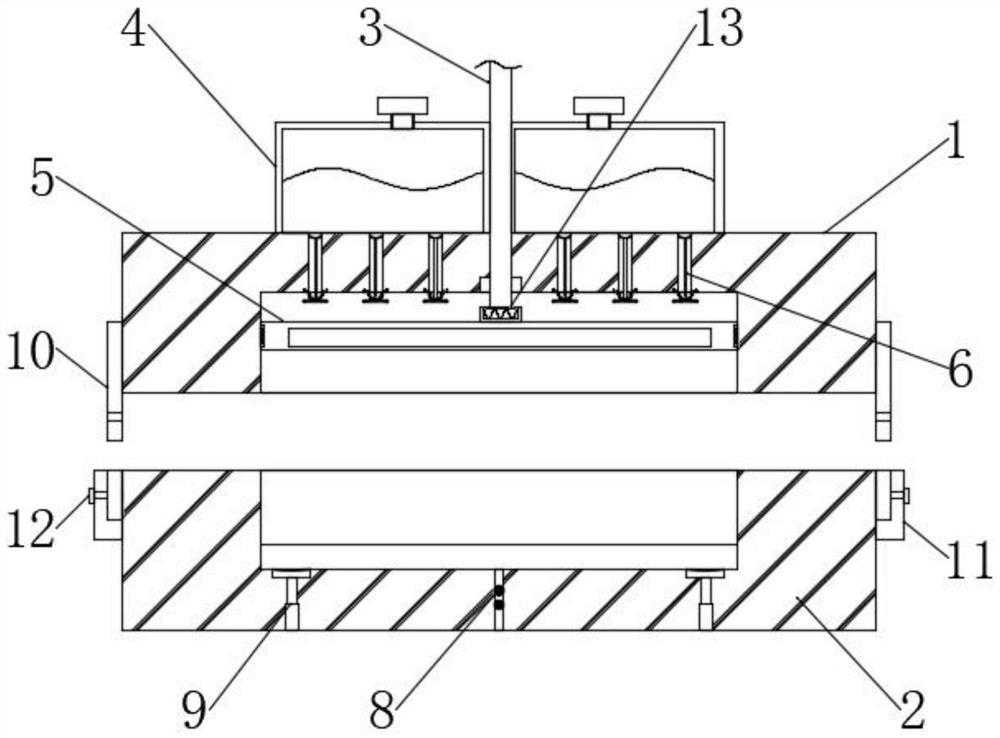

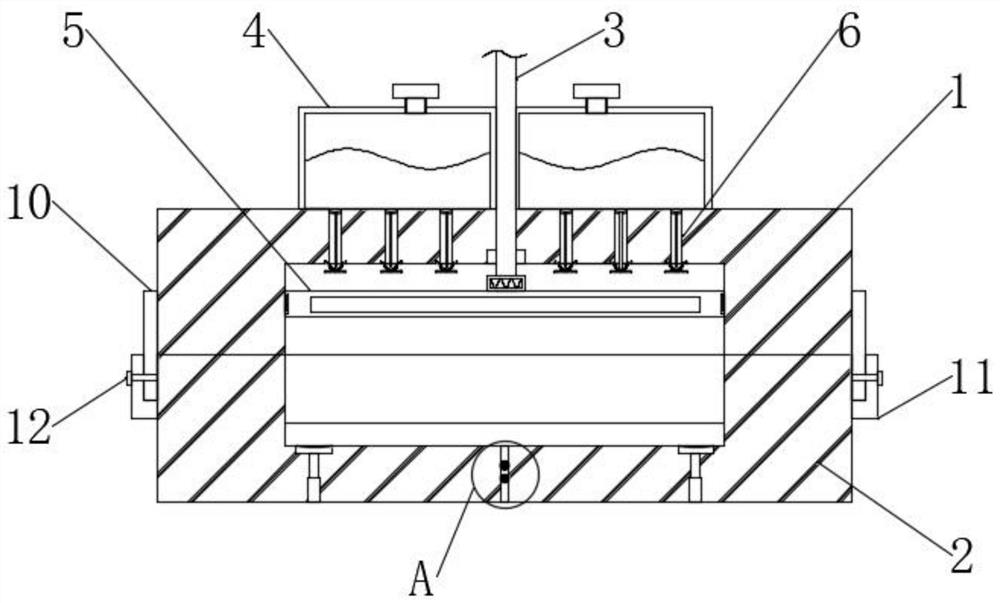

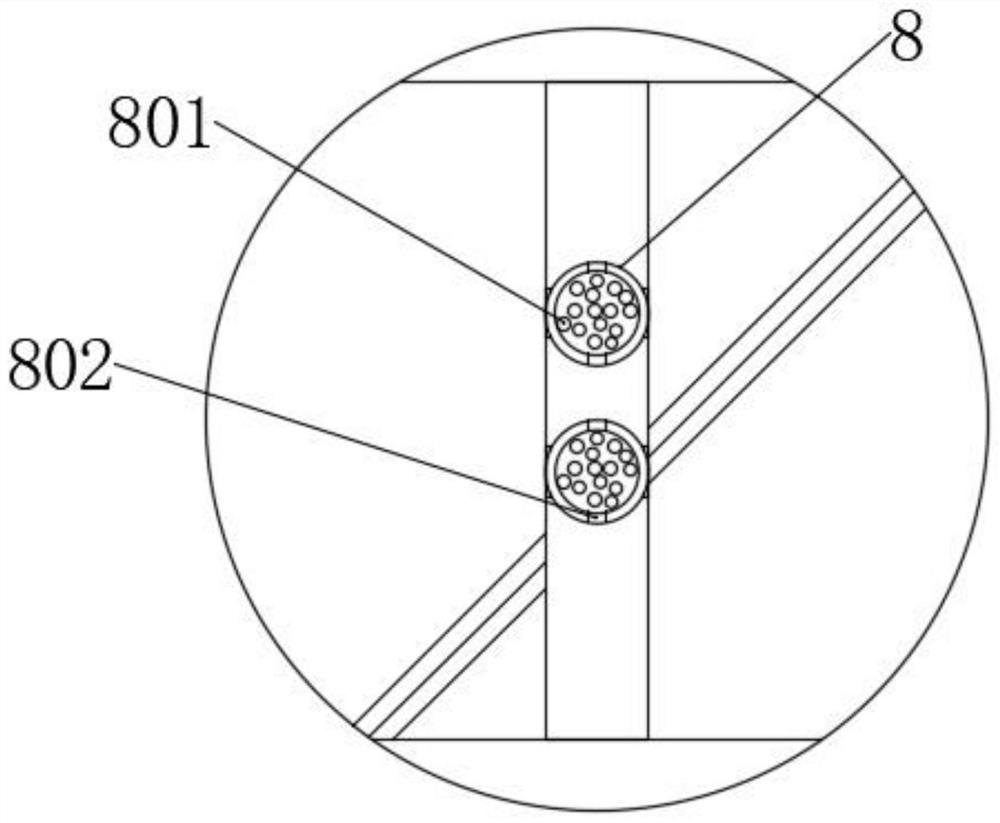

[0043] see Figure 1-2 , a mold for high-strength ratchet shaft processing, including an upper mold base 1, the lower side of the upper mold base 1 is provided with a lower mold base 2 matching the upper mold base 1, and the upper side of the upper mold base 1 is provided with an electric telescopic Rod 3, the electric telescopic rod 3 runs through the upper mold base 1 and extends into the upper mold base 1, the upper end of the upper mold base 1 is fixedly connected with the storage bin 4, the storage bin 4 is filled with casting materials, and the lower end of the electric telescopic rod 3 is fixed An electromagnet 13 is connected, and the lower end of the electromagnet 13 is adsorbed with a pressure exhaust plate 5. The upper end of the upper mold base 1 is provided with a plurality of discharge holes matching the storage bin 4, and the storage bin 4 is fixedly connected with a uniform Outlet filtering device, the lower mold base 2 is provided with a docking groove matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com