OWTS power cable oscillation wave test equipment and test method

An oscillatory wave test, power cable technology, applied in the direction of test circuit, test dielectric strength, fault location, etc., can solve the problems of difficult field test, long charging time, large power capacity, etc. Experimental, the effect of a large capacitance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

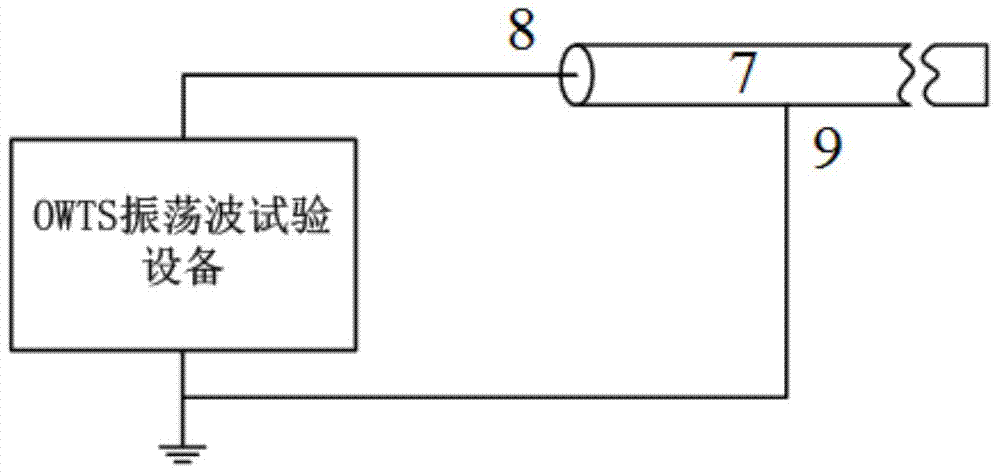

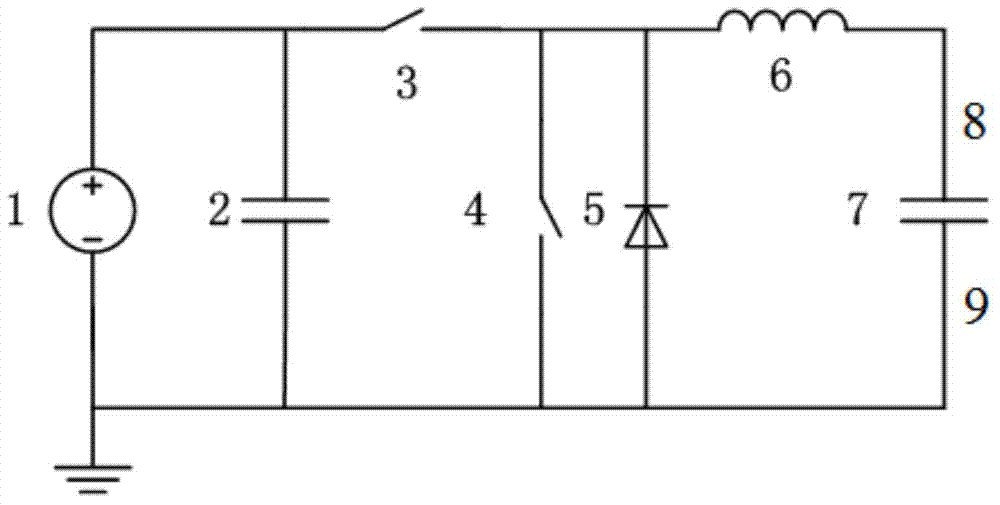

Embodiment 1

[0037] When the DC high voltage power supply 1 charges the capacitor 2 by 10kV, the capacity of the capacitor 2 is selected as 10μF, the reactor inductance is selected as 0.7H, and the capacitance of the cable to be tested is 0.05μF, the voltage on the cable can be 0.69 after the first high voltage electronic switch 3 is closed. The ms reaches 17.11kV. After the second high-voltage electronic switch 4 is closed, an attenuated oscillation wave of 851.5 Hz is formed on the cable.

Embodiment 2

[0039] When the DC high voltage power supply 1 charges the capacitor 2 by 10kV, the capacity of the capacitor 2 is selected as 20μF, the reactor inductance is selected as 0.8H, and the capacitance of the cable to be tested is 2μF, the voltage on the cable can be 0.68ms after the first high voltage electronic switch 3 is closed. Up to 16.88kV, after the second high-voltage electronic switch 4 is closed, an attenuated oscillation wave of 134.5 Hz is formed on the cable.

Embodiment 3

[0041] When the DC high voltage power supply 1 charges the capacitor 2 by 20kV, the capacitor 2 capacity is selected as 20μF, the reactor inductance is selected as 1H, and the cable capacity to be tested is 4μF, the voltage on the cable can reach 5.9ms after the first high voltage electronic switch 3 is closed. 32.7kV, after the second high-voltage electronic switch 4 is closed, an attenuated oscillation wave of 79.5 Hz is formed on the cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com