Modular feeder terminal

A feeder terminal and modular technology, applied in the field of feeder terminals, can solve problems affecting the safe and stable operation of power distribution terminal equipment, increase engineering costs of CT lines and control cables, and limited space resources of ring main units, so as to eliminate power distribution Risk of network failure, reduction of installation steps, effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

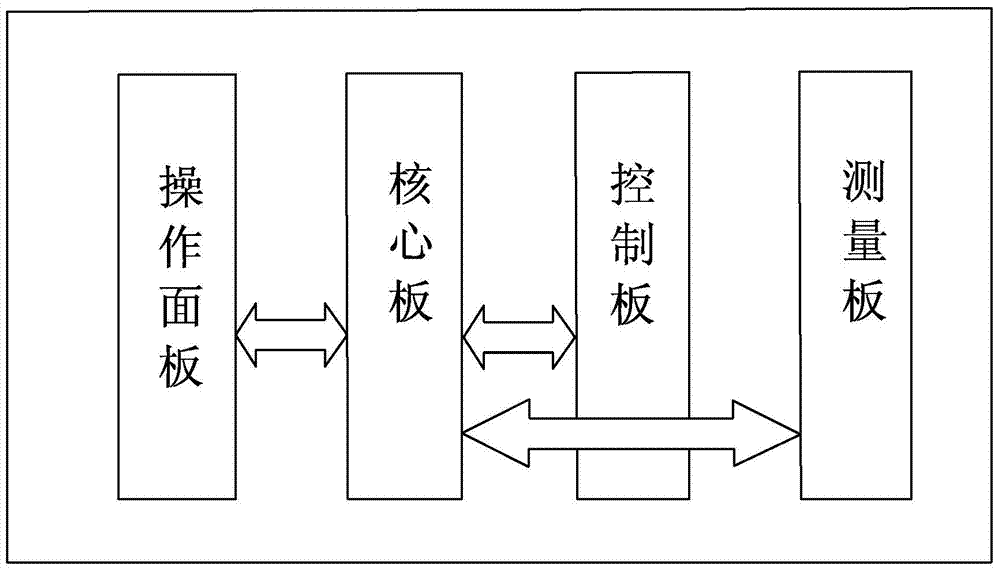

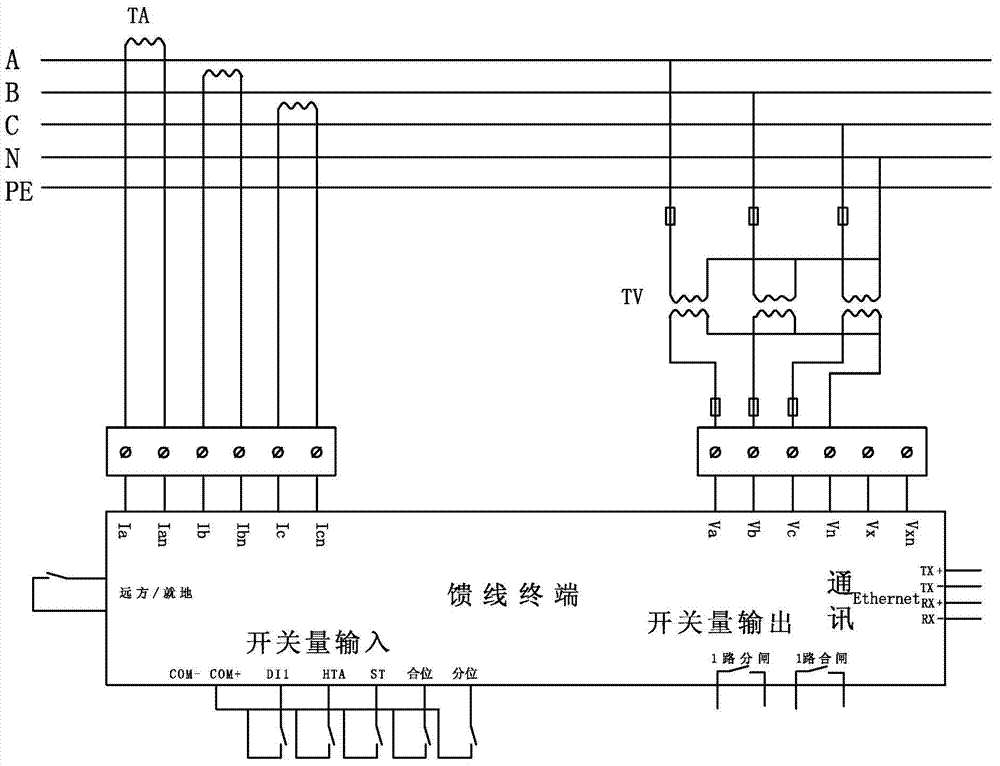

[0021] Please check figure 1 and figure 2 , a modular feeder terminal for mounting in a switchgear cabinet, which includes a housing and a core board 10 , a control board 20 , a measurement board 30 and an operation panel 40 installed in the housing.

[0022] The core board 10 is connected to the control board 20, the measurement board 30 and the operation panel 40, processes and calculates the data sent on the control board 20 and the measurement board 30 (fault current, voltage, grounding, etc.), and sends instruction information to the operator Panel 40 is displayed. The core board 10 supports DC220V or DC48V power input. The core board 10 is provided with a network interface 11 and a remote / local access port 12 of the switch cabinet, and the network interface 11 and the remote / local access port 12 are connected outside the casing. In this embodiment, the network interface 11 is the RJ45 network interface. In this embodiment, the connection between the core board 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com