Plasma photonic crystal generating device

A photonic crystal and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems of small size of plasma photonic crystal and difficult control of plasma parameter changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A device for generating a plasmonic photonic crystal according to the present invention will be described in detail below with reference to the drawings and embodiments.

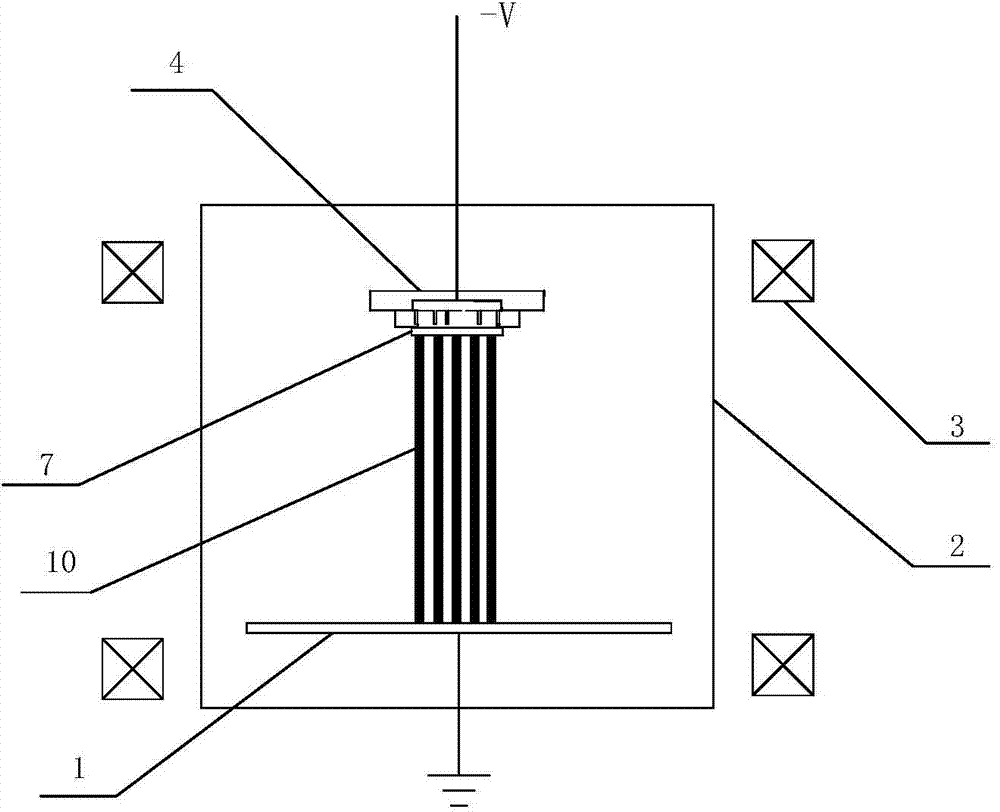

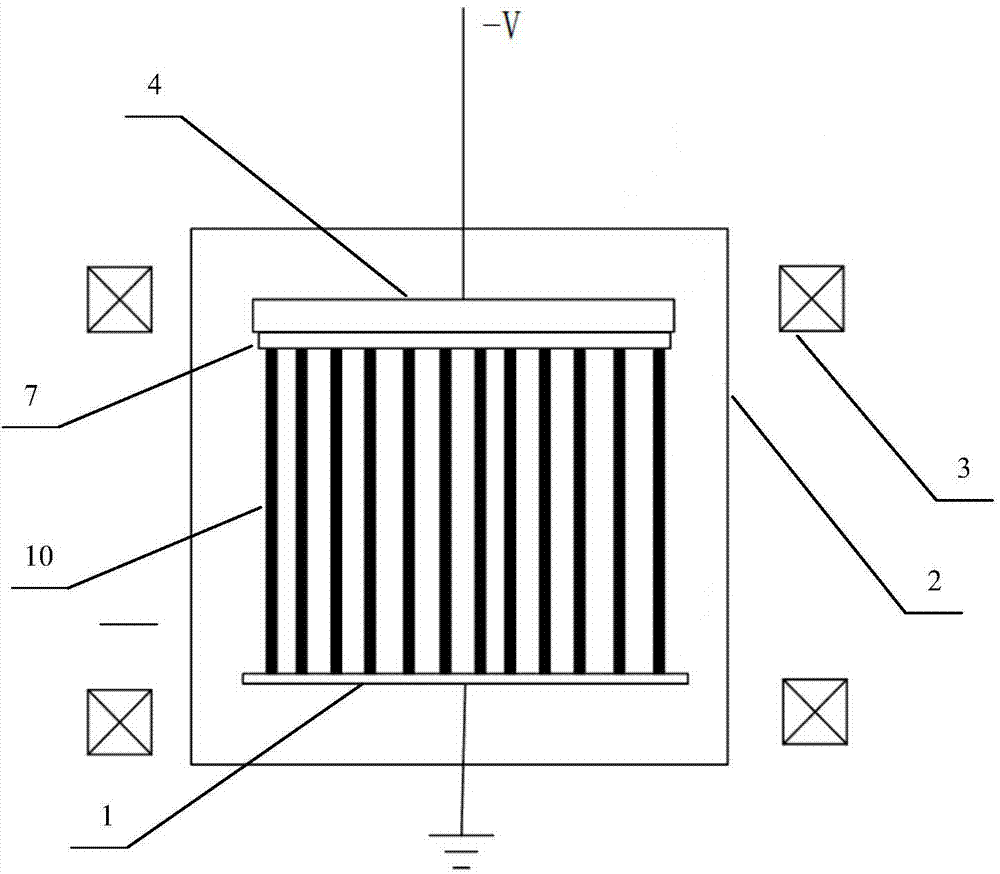

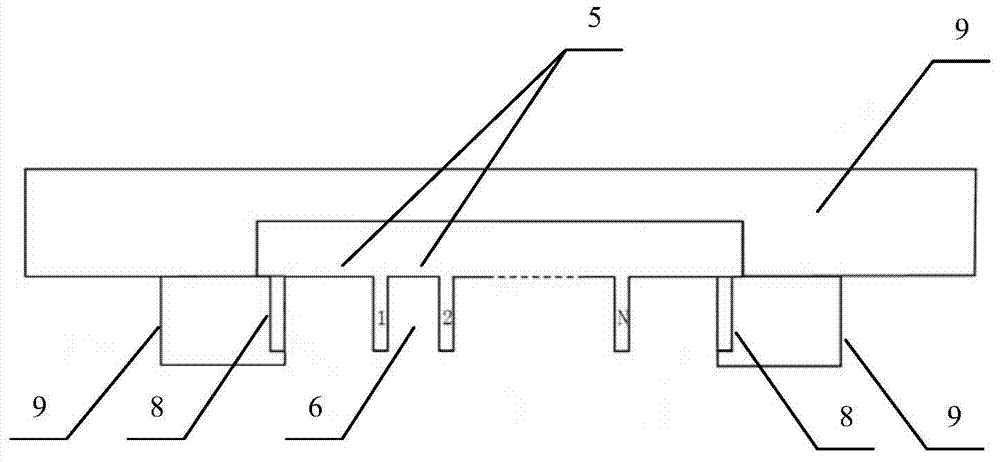

[0030] Such as figure 1 , 2 As shown, a device for generating plasma photonic crystals of the present invention includes: an anode plate 1, a combined hollow cathode 4, a vacuum discharge chamber 2 and a Helmholtz coil set outside the vacuum discharge chamber 2 3. The vacuum discharge chamber 2 is coaxially arranged with the Helmholtz coil 3; the combined hollow cathode 4 is arranged in the vacuum discharge chamber 2 opposite and parallel to the anode plate 1; as image 3 As shown, the combined hollow cathode includes several T-shaped cathode bottom plates 5; the T-shaped cathode bottom plates 5 are arranged in parallel on the same plane, and a concave hole is formed between two adjacent T-shaped cathode bottom plates 5. Slotted cathode 6; as figure 1 , 2 As shown, the bottom of the combined hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com