Semi-screen complex chain collection type root-tuber crop harvester

A harvester and frame technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of poor harvesting quality, low harvesting efficiency, and few types of harvesting, so as to solve congestion problems, improve harvesting efficiency, Improve the effect of crushing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

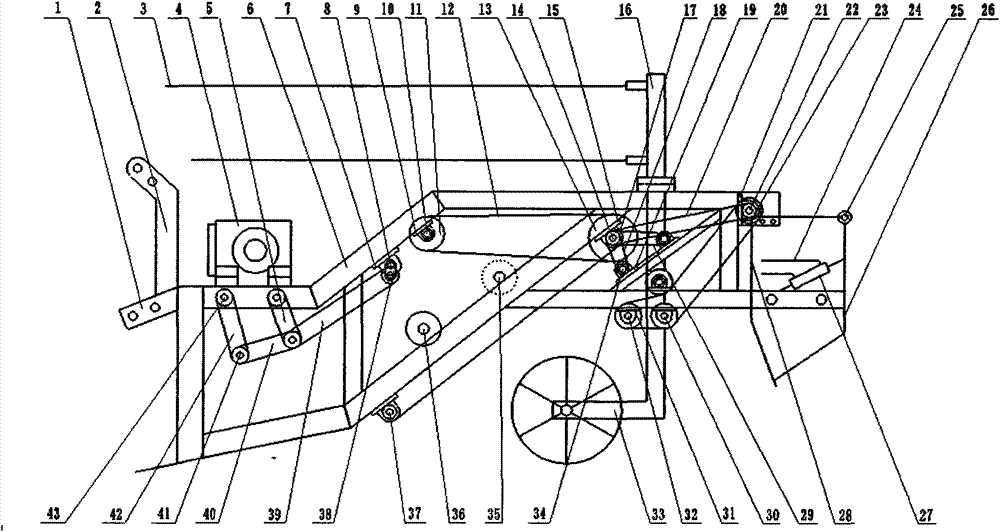

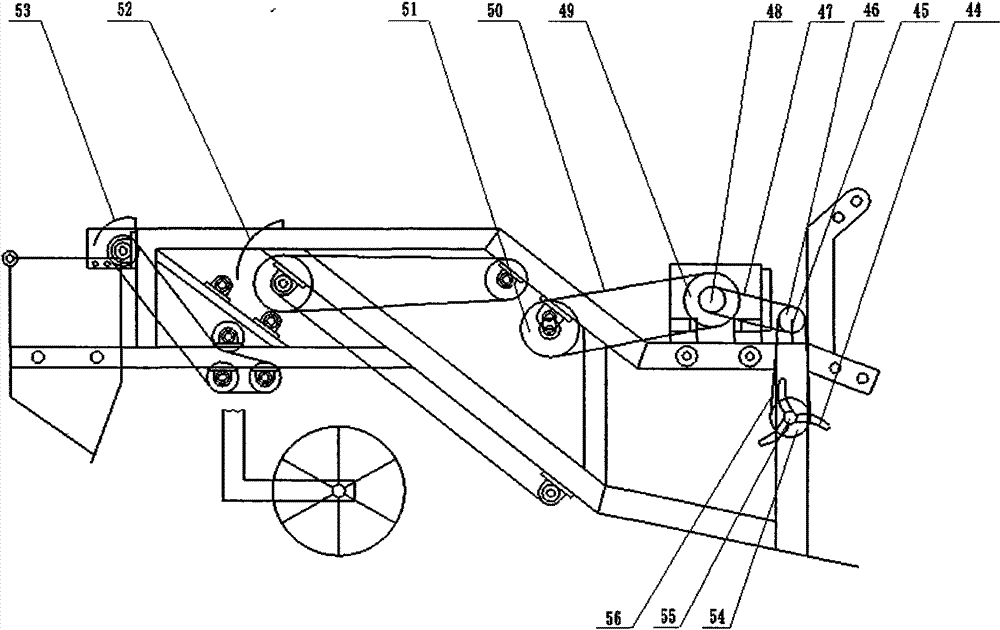

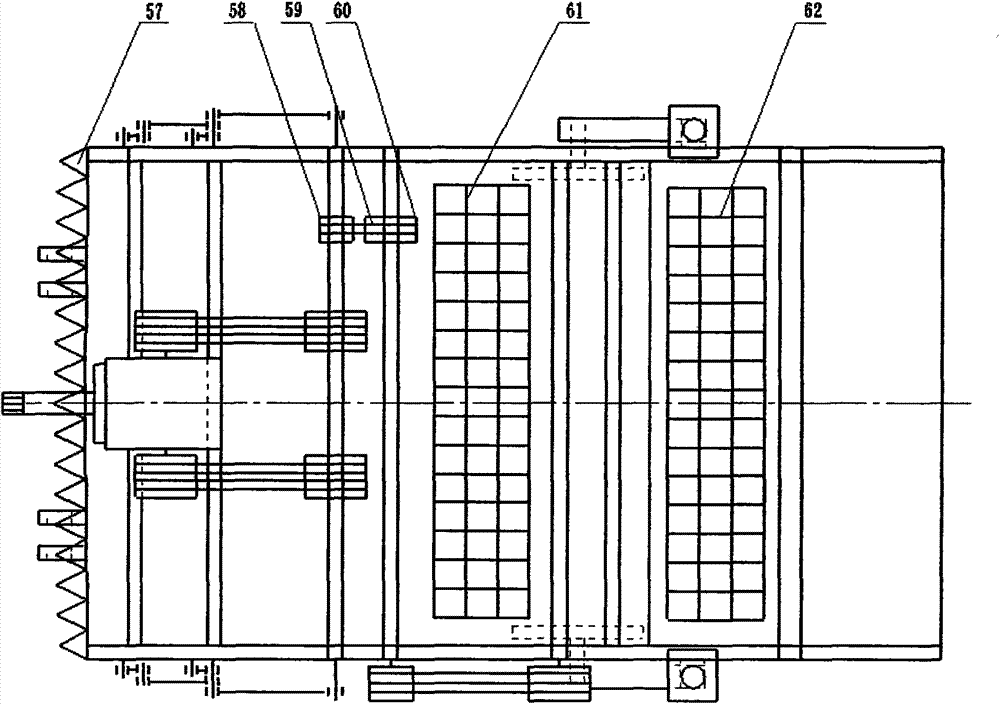

[0015]A semi-sieve compound chain collection type rhizome crop harvester, as shown in the accompanying drawings, it consists of a lower suspension frame 1, an upper suspension frame 2, a ground wheel oil pipe 3, a gearbox 4, a rear rocker arm 5, a frame 6, a main Bearing 7, main shaft 8, intermediate shaft bearing 9, intermediate shaft 10, intermediate shaft pulley 11, transmission chain belt 12, transmission chain pulley 13, transmission chain main shaft 14, transmission chain main bearing 15, ground wheel oil cylinder 16, transmission wheel Group 17, lower broken soil transmission belt 18, broken soil shaft bearing bush 19, multiple transmission chain belt 20, double chain main bearing bush 21, double chain main shaft 22, double chain main shaft pulley 23, collection box oil pipe 24, box cover shaft 25, box Cover 26, collection box oil cylinder 27, box body 28, upper broken soil transmission belt 29, pressure chain shaft combination 30, double chain slave bearing bush 31, dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com