A kind of yogurt added with chia seeds and preparation method thereof

A technology of chia seeds and yogurt, which is applied in the field of yogurt with chia seeds and its preparation, can solve the problem that compound stabilizers cannot meet consumers' healthy dietary needs, and achieve good stability, taste and flavor, and smooth gelatin sense, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Raw material formula (measured in 1000g):

[0066] Fresh milk: 904.92g; white sugar: 90g; chia seeds: 5g; starter: 0.08g (Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus).

[0067] 2. Production method:

[0068] (1) Preparation method of main ingredients of yogurt:

[0069] 1) Mix the above-mentioned yogurt ingredients except the starter at 65°C for 30 minutes, and mix well;

[0070] 2) The mixed material obtained in step 1) is degassed and homogenized at 65°C and 18MP pressure;

[0071] 3) The homogenized mixed material is sterilized at 95°C for 300s;

[0072] 4) Cool to 42°C, add starter;

[0073] 5) Ferment at 42°C until the acidity reaches 74°T, stop the fermentation and make yogurt;

[0074] 6) Cool down to 20°C, pour into the yogurt buffer tank and prepare for filling.

[0075] (2) Chia seeds can be processed in accordance with the following operations:

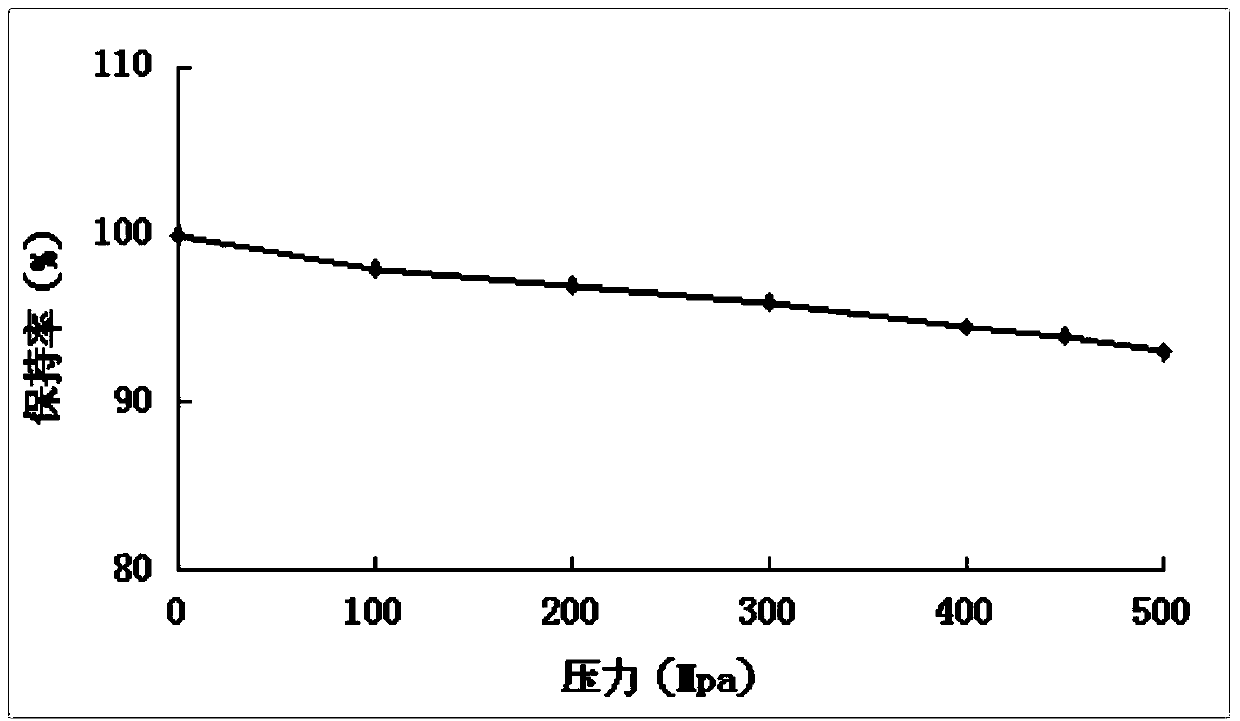

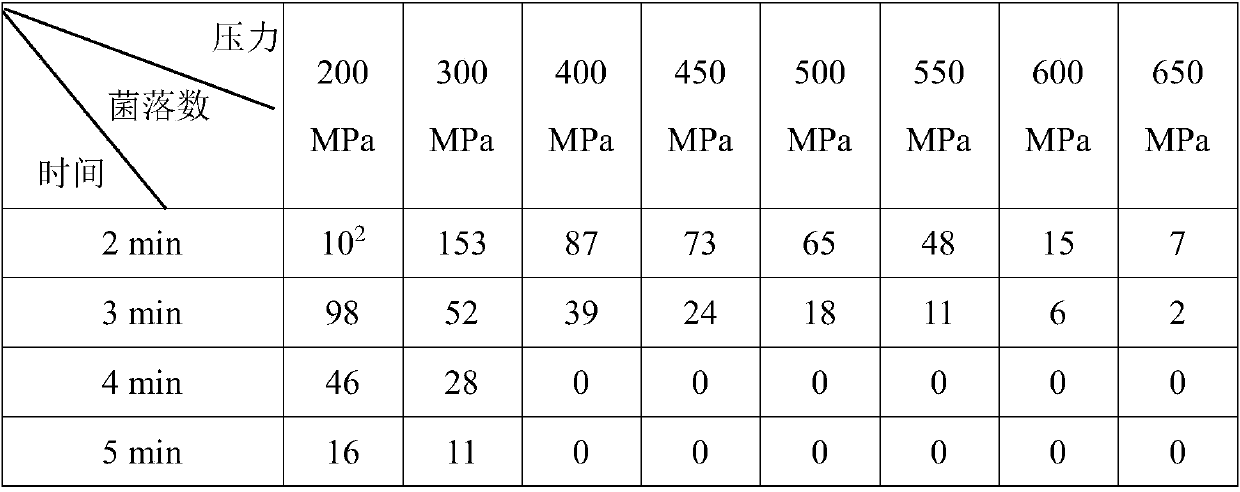

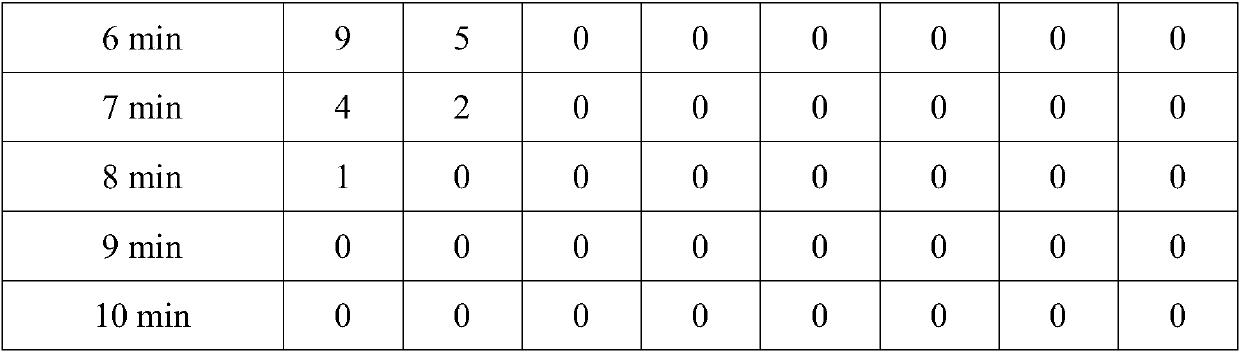

[0076] Put the removed chia seeds in a polyethylene composite bag fo...

Embodiment 2

[0079] 1. Raw material formula (measured in 1000g):

[0080] Fresh milk: 919.9g; white sugar: 70g; chia seeds: 10g; starter: 0.1g (Streptococcus thermophilus, Lactobacillus bulgaricus, Bifidobacterium breve, Bifidobacterium longum).

[0081] 2. Production method:

[0082] (1) Preparation method of main ingredients of yogurt:

[0083] 1) Mix the above-mentioned yogurt ingredients except the starter at 60°C for 32 minutes, and mix well;

[0084] 2) The mixed material obtained in step 1) is degassed and homogenized at 60°C and 20MP pressure;

[0085] 3) The homogenized mixture is sterilized at 110°C for 10 minutes;

[0086] 4) Cool to 43°C, add starter;

[0087] 5) Ferment at 43°C until the acidity reaches 76°T, stop the fermentation and make yogurt;

[0088] 6) Cool down to 22°C, pour into the yogurt buffer tank and prepare for filling.

[0089] (2) Chia seeds can be processed in accordance with the following operations:

[0090] Put the removed chia seeds in a polyethyle...

Embodiment 3

[0093] 1. Raw material formula (measured in 1000g):

[0094] Fresh milk: 934.91g; white sugar: 50g; chia seeds 15g; starter: 0.09g (Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, Bifidobacterium adolescentis).

[0095] 2. Production method:

[0096] (1) Preparation method of main ingredients of yogurt:

[0097] 1) Mix the above-mentioned yogurt ingredients except the starter at 55°C for 35 minutes, and mix well;

[0098] 2) The mixed material obtained in step 1) is degassed and homogenized at 60°C and 20MP pressure;

[0099] 3) The homogenized mixed material is sterilized at 121°C for 4s;

[0100] 4) Cool to 42°C, add starter;

[0101] 5) Ferment at 42°C until the acidity reaches 78°T, stop the fermentation and make yogurt;

[0102] 6) Cool down to 24°C, pour into the yogurt buffer tank and prepare for filling.

[0103] (2) Chia seeds can be processed in accordance with the following operations:

[0104] The removed chia seeds were vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com