Sugar boiling pot for producing candy

A technology for boiling sugar pot and candy, which is applied in the field of sugar cooking pot, can solve the problems of shortening the service life of the machine and increasing the load of the mixer, and achieves the effect of overcoming the vortex and reducing the loss of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

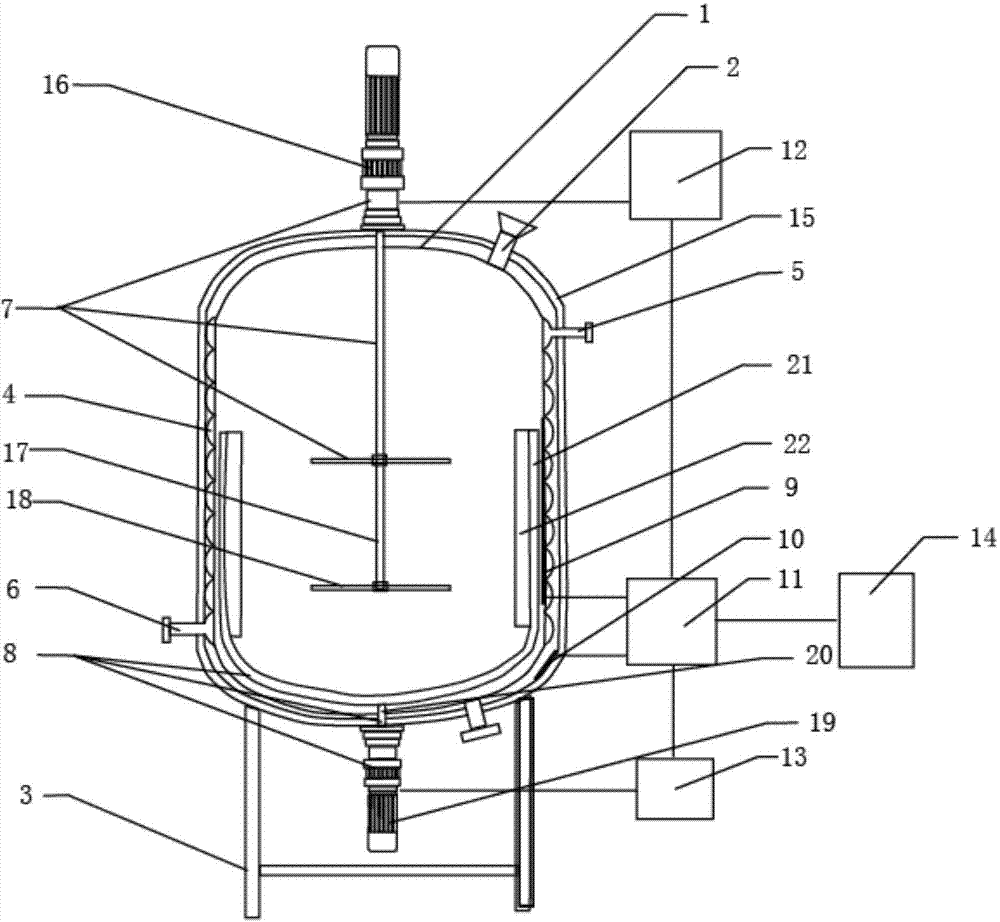

[0010] The present invention will be further explained below in conjunction with accompanying drawing.

[0011] Such as figure 1 As shown, it includes a kettle body 1, a feed inlet 2, a support frame 3, a heating sleeve 4, a steam inlet 5, a steam outlet 6, a first stirring mechanism 7, a second stirring mechanism 8, a viscosity sensor 9, a temperature sensor 10, The control device 11, the first drive device 12, the second drive device 13, the display device 14, the insulation layer 15, the feed inlet 2 is arranged on the upper part of the kettle body 1, the heating sleeve 4 is arranged on the outside of the kettle body 1, and the heating jacket The upper end of the pipe 4 is connected to the steam inlet 5, and the lower end is connected to the steam outlet 6. The first stirring mechanism 7 includes a first frequency conversion motor 16, a first stirring shaft 17, and paddle stirring blades 18. The second stirring mechanism 8 includes a second frequency conversion motor. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com