A method and device for efficiently utilizing coal gas output from a smelting reduction furnace

A reduction furnace and coal gas technology, which is applied in the field of efficient utilization of coal gas output from smelting reduction furnaces, can solve problems such as low-value utilization, and achieve the effects of energy saving, emission reduction, reduction metallization rate, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

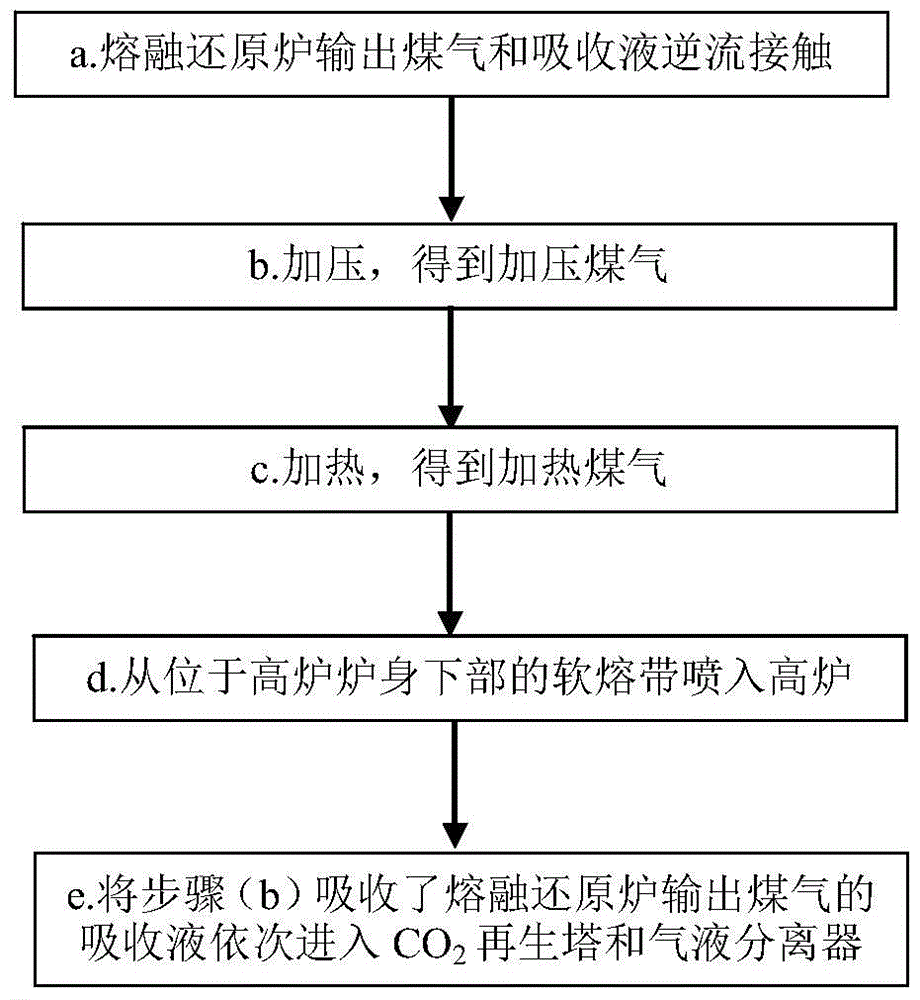

Method used

Image

Examples

Embodiment 1

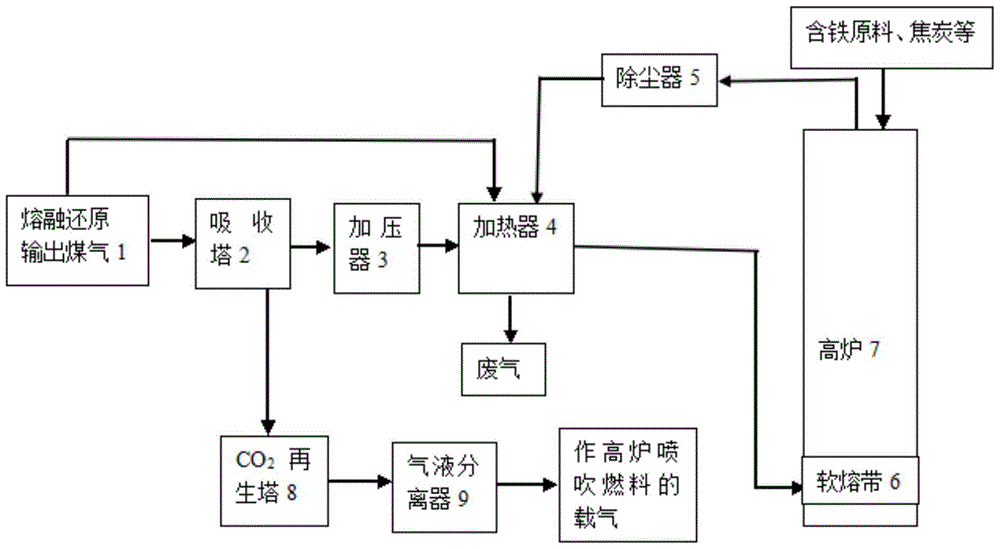

[0050] A smelting reduction furnace outputs coal gas A, whose composition is shown in Table 1. NaOH lye is absorbed through the bubble tower. The diameter of the bubble tower is 3 meters and the height is 15 meters. There are 12 distribution plates in the tower. The diameter is 2.8 meters, and the gas and lye flow countercurrently to achieve full absorption. The composition is shown in Table 2. It is pressurized to 0.4MPa by 3 sets of D800 gas pressurizers, and then heated by a JDK type gas heater to 970°C, spray 2500m 3 Blast furnace, the amount of injected gas is 250,000m 3 / h, the lye that absorbs the output gas A of the smelting reduction furnace is passed into CO 2 Regeneration tower, the regeneration tower is a foam tower, which uses saturated steam for regeneration. The diameter of the regeneration tower is 3 meters, and the height is 17 meters. There are 13 distribution plates in the tower, and the diameter of the distribution plate is 2.8 meters. Then it is passed i...

Embodiment 2

[0053] A smelting reduction furnace outputs coal gas B, whose composition is shown in Table 1. KOH lye is absorbed through the bubble tower. The diameter of the bubble tower is 3 meters and the height is 15 meters. There are 12 distribution plates in the tower. The diameter is 2.8 meters, and the gas and lye flow countercurrently to achieve full absorption. The composition is shown in Table 2. It is pressurized to 0.45MPa by 3 sets of D800 gas pressurizers, and then heated by a JDK type gas heater To 1000℃, spray 2000m 3 Blast furnace, the amount of injected gas is 200,000m 3 / h, the lye that absorbs the output gas B of the smelting reduction furnace is passed into CO 2 Regeneration tower, the regeneration tower is a foam tower, which uses saturated steam for regeneration. The diameter of the regeneration tower is 3 meters, and the height is 17 meters. There are 13 distribution plates in the tower, and the diameter of the distribution plate is 2.8 meters. Then it is passed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com