Large/complex underground pump room configuration method and application

A configuration method and pump room technology, applied in water supply devices, waterway systems, industrial buildings, etc., can solve the problems of increased difficulty in installation and maintenance of pump room equipment, increased depth and complexity of underground pump rooms, installation and observation of flowmeters Difficulty and other problems, to achieve the effect of facilitating the layout of pipelines, convenient operation, and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

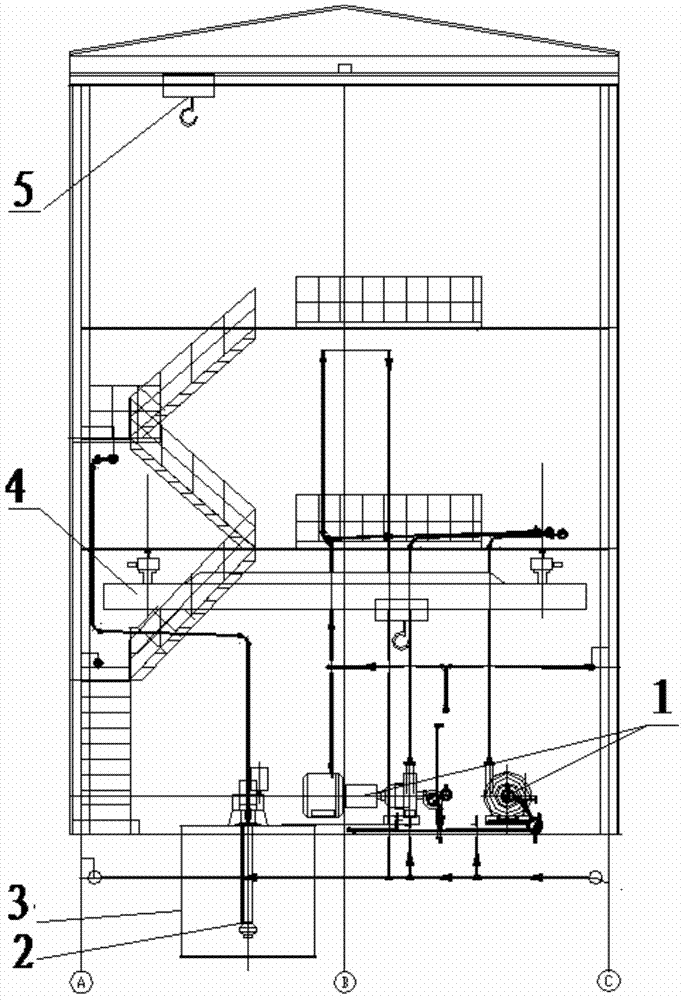

[0010] The present invention will be further described below in conjunction with accompanying drawing. The flotation concentrate and tailings slurry from the underflow of the thickener is transported to the concentrate and tailings filtering section through the slurry pump in the underground pump room for filtration. The underground pump room includes sewage tanks (pit), sewage pumps, etc.

[0011] Such as figure 1 The configuration method of the large (complex) underground pump room of the present invention is shown, the slurry pump 1 is set on the ground of the pump room, the sewage tank 3 is set below the ground of the pump room, the sewage pump 2 is set in the sewage tank 3, and the middle part of the pump room A crane 4 is set in the height space, and an electric hoist 5 is set on the top of the pump room; the crane 4 and the electric hoist 5 can directly lift the slurry pump 1, the sewage tank 3 and the sewage pump 2.

[0012] The crane 4 is a suspension crane, and ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com