Colloid removing method of quad flat no-lead packaging chip

A leadless packaging, square and flat technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of difficult removal of residual glue 31

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above and other purposes, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

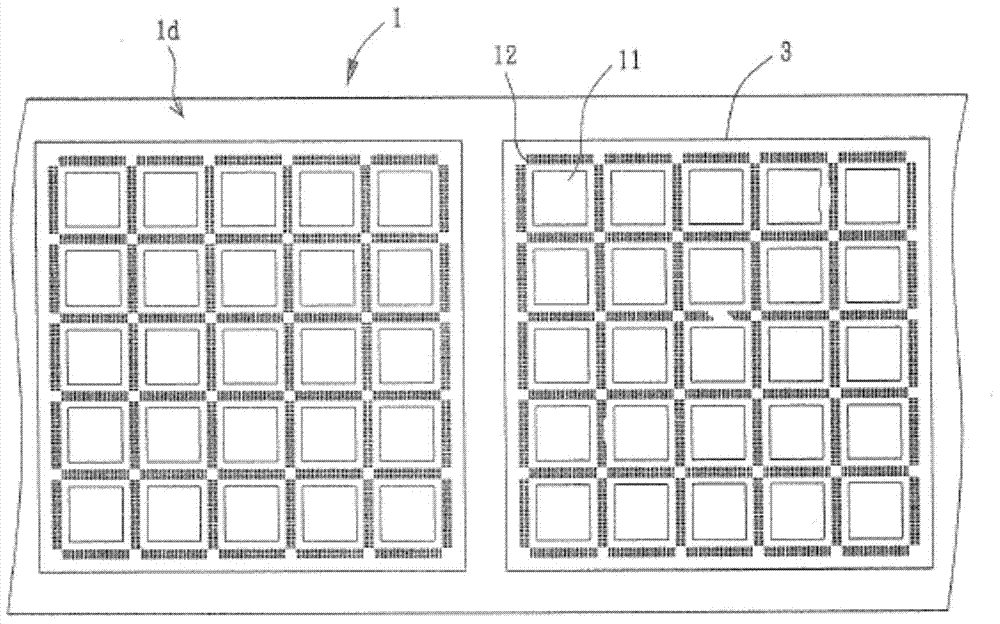

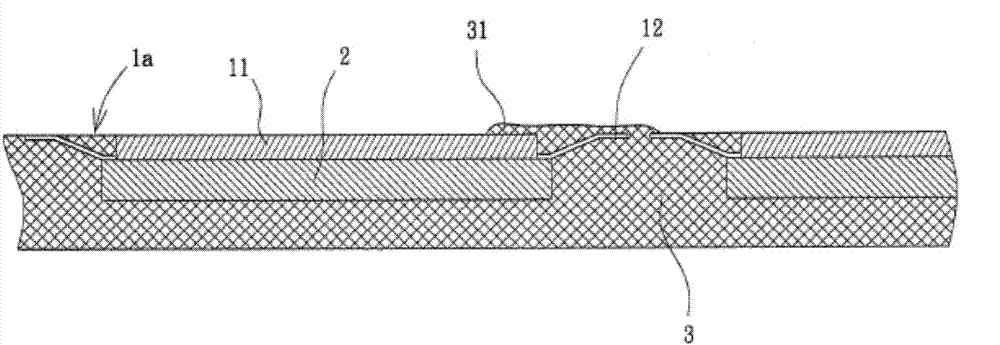

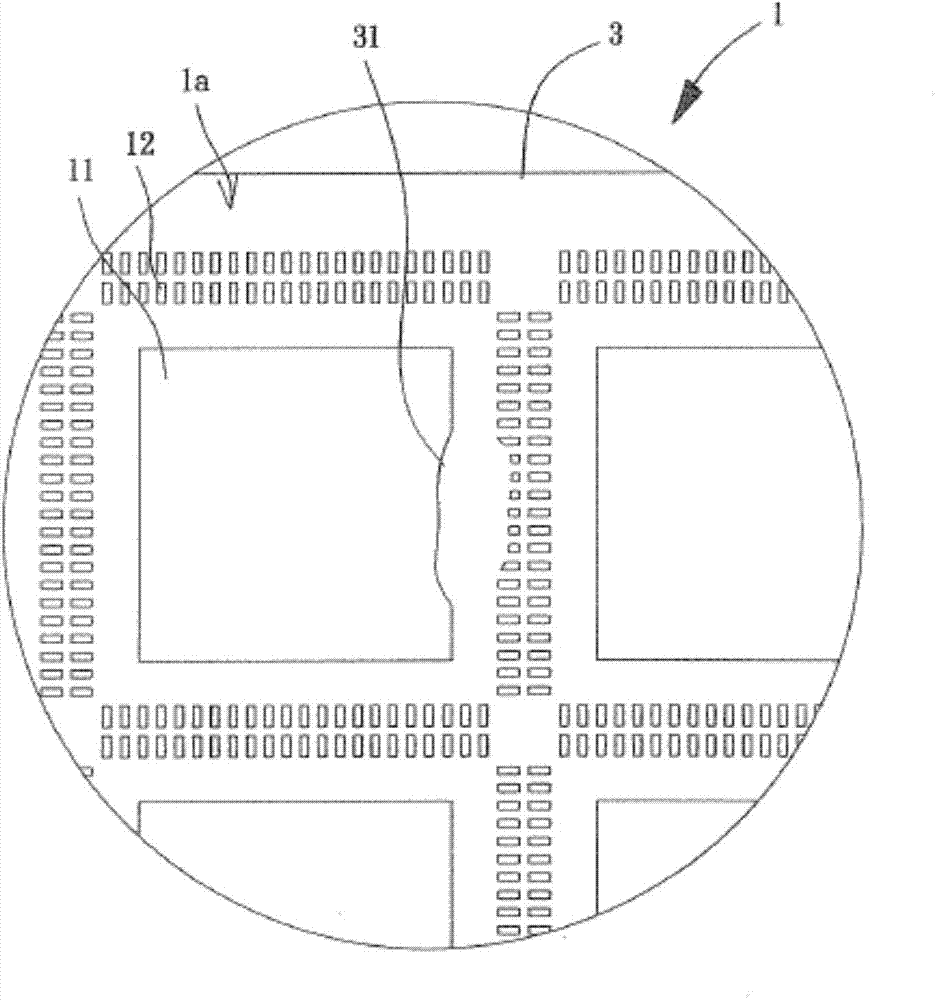

[0036] Please refer to Figure 4 Shown is a flow chart of a method for removing glue from a square flat no-lead package chip according to a preferred embodiment of the present invention. First, if Figure 5 and 6As shown, an image of a region R on the surface 1a of the substrate 1 is captured by a photomicrograph C. The photomicrograph C can be a Charge Coupled Device (CCD) camera or a complementary metal oxide Complementary Metal-Oxide Semiconductor (CMOS) camera, etc., and then use a computing unit to load the image of the region R, and perform image analysis operations to identify each heat sink 11 in the region R, and locate all heat sinks in the substrate 1 Packaged Die 2 Position. Please also refer to Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com