Preparation method of layered lithium-rich sosoloid cathode material

A positive electrode material and solid solution technology, which is applied in the field of preparation of layered lithium-rich solid solution positive electrode materials, can solve the problems of undisclosed literature and patents on the stability control of total alkali content on the surface, and achieve high-temperature cycle and storage performance. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

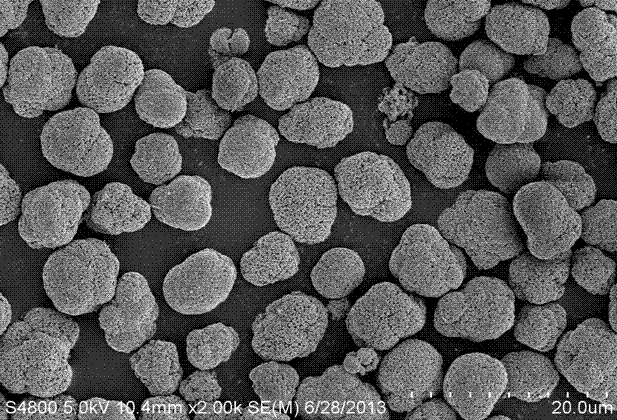

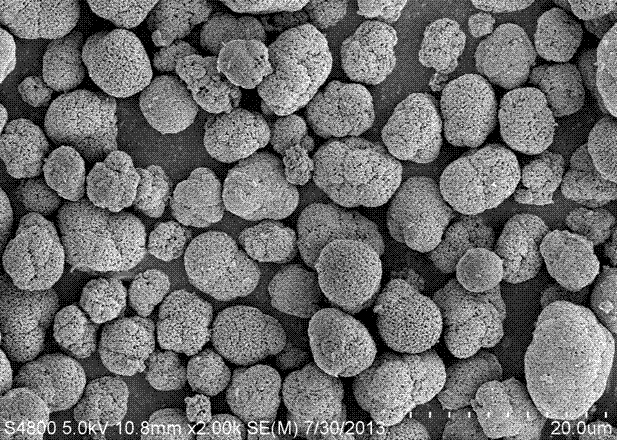

Image

Examples

Embodiment 1

[0029] 1.2 According to the molecular formula of step 1, weigh an excess of Li with a molar ratio of 5% 2 CO 3 , will Li 2 CO 3 After mixing with the precursor obtained in step 1.2, heat up to 550°C for sintering in air or an oxygen-containing atmosphere for 6 hours, and then heat up to 850°C for high-temperature sintering for 10 hours. That is, the intermediate product of the layered lithium-rich manganese-based material is obtained.

[0030] 2. Layered lithium-rich solid solution material reduces surface residual alkali steps:

[0031]Dissolve the layered lithium-rich solid solution material in step 1.2 in deionized water equivalent to 100% by weight, slurry, stir and wash at 75°C for 3 times until the powder pH<10.8, filter and dry it to obtain the positive electrode active material.

[0032] 3. Surface coating modification steps of layered lithium-rich solid solution materials:

[0033] 100g of the lithium-rich solid solution cathode material synthesized above and 50...

Embodiment 2

[0037] 1.2 Weigh an excess of 10% LiOH according to the molecular formula in step 1, mix LiOH with the precursor obtained in step 1, heat up to 600°C for 5 hours in air or an oxygen-containing atmosphere, and then heat up to 900°C for 12 hours at high temperature . That is, the intermediate product of the layered lithium-rich manganese-based material is obtained.

[0038] 2. Layered lithium-rich solid solution material reduces surface residual alkali steps:

[0039] Dissolve the layered lithium-rich solid solution material precursor in step 2 in deionized water equivalent to 200% by weight of it, rinse it at 50°C for 4 times until the powder pH<10.5, filter and dry it to obtain the positive electrode active material.

[0040] 3. Surface coating modification steps of layered lithium-rich solid solution materials:

[0041] 100g of the lithium-rich solid solution cathode material synthesized above and 30g of ZrO with a solid content of 0.25% 2 The nano-suspension suspension i...

Embodiment 3

[0045] 1.2 According to the molecular formula of step 1, weigh an excess of 15% Li with a molar ratio 2 CO 3 , will Li 2 CO 3 After mixing with the precursor obtained in step 1, heat up to 600° C. for sintering in air or an oxygen-containing atmosphere for 5 hours, and then heat up to 880° C. for high-temperature sintering for 15 hours. That is, a layered lithium-rich solid solution material intermediate is obtained.

[0046] 2. Layered lithium-rich solid solution material reduces surface residual alkali steps:

[0047] Dissolve the layered lithium-rich solid solution material precursor in step 2 in deionized water equivalent to 200% by weight, slurry, stir and wash twice at 90°C, then rinse with pure water until the powder pH<10.5, It was filtered and dried to obtain the positive electrode active material.

[0048] 3. Surface coating modification steps of layered lithium-rich solid solution materials:

[0049] 150 g of the lithium-rich manganese-based cathode material s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com