Large-crystal ternary positive electrode material of lithium ion battery and preparation method of large-crystal ternary positive electrode material

A lithium-ion battery and cathode material technology, applied in the field of materials, can solve the problems of high residual alkali on the surface of materials, poor thermal stability, and poor cycle stability, and achieve good high-temperature cycle and storage performance, strong applicability, and good rate performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

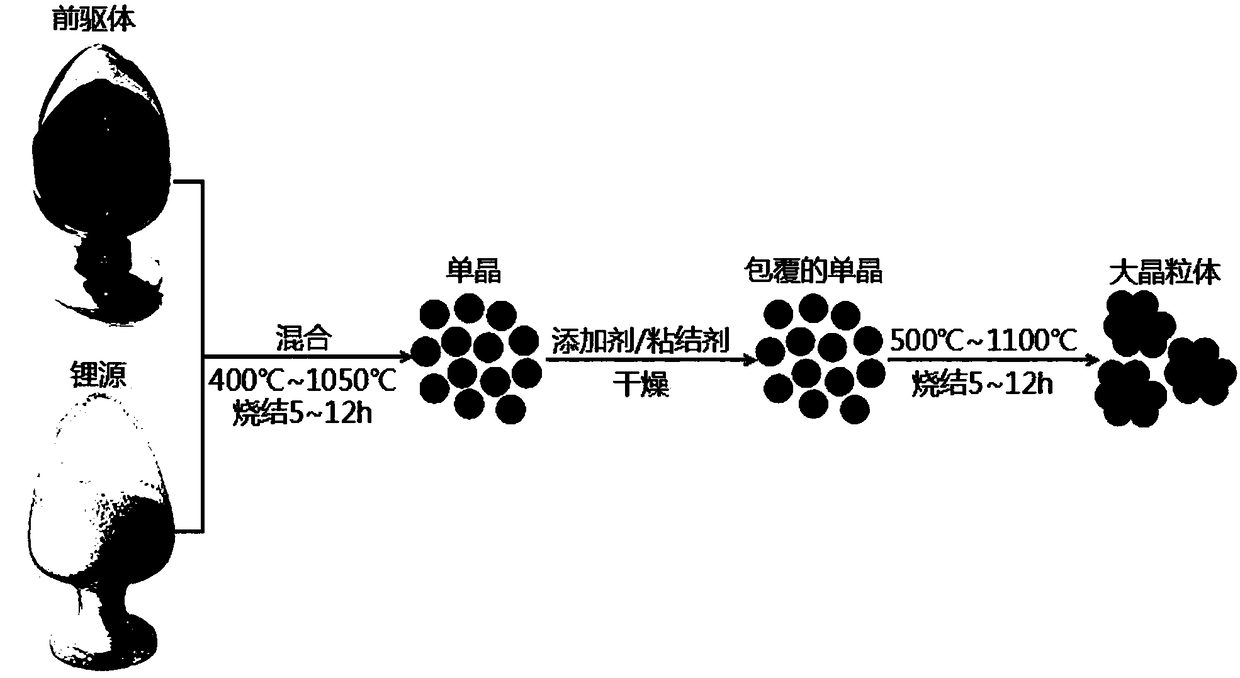

[0033] The preparation method of the lithium-ion battery large-grain body ternary positive electrode material provided by the invention, such as figure 1 As shown, it mainly includes the following steps:

[0034] (1) Mix the nickel-cobalt-manganese precursor and the lithium source according to Li(mol) / NiCoMn(mol)=1.00-1.20, sinter at 400°C-1050°C for 5-12h, cool to room temperature and crush to obtain single crystal particles ;

[0035] Specifically, the nickel-cobalt-manganese precursor may include: Ni x co y mn z (OH) 2 、Ni x co y mnz CO 3 、Ni x co y mn z O, Ni x co y mn z SO 4 Any one or more of them, where x+y+z=1;

[0036] Specifically, the lithium source may include: lithium carbonate, lithium hydroxide, lithium oxide, lithium peroxide, lithium superoxide, lithium nitrate, lithium nitrite, lithium sulfate, lithium sulfite, lithium thiosulfate, lithium silicate, chlorine Any one or more of lithium chloride, lithium bromide, lithium iodide, lithium sulfide,...

Embodiment 1

[0054] Take Ni 0.5 co 0.2 mn 0.3 (OH) 2 Mix with lithium carbonate (Li(mol) / NiCoMn(mol)=1.06), sinter at 800°C for 8h, cool to room temperature and then break; disperse the intermediate product in the ethanol solution of nano-titanium dioxide and polyethylene oxide PEO (in ethanol Under stirring state, add 0.3% by weight of titanium dioxide and 0.5% by weight of polyethylene oxide (PEO) respectively, stir for 1 hour, dry; sinter at 1000°C for 8 hours, cool to room temperature (about 25°C, the same below), crush and sieve ; Obtain the large grain body ternary positive electrode material of the lithium ion battery.

[0055] In this embodiment, the large-grain body ternary positive electrode material of the lithium-ion battery is LiNi 0.5 co 0.2 mn 0.3 o 2 / titanium dioxide complex.

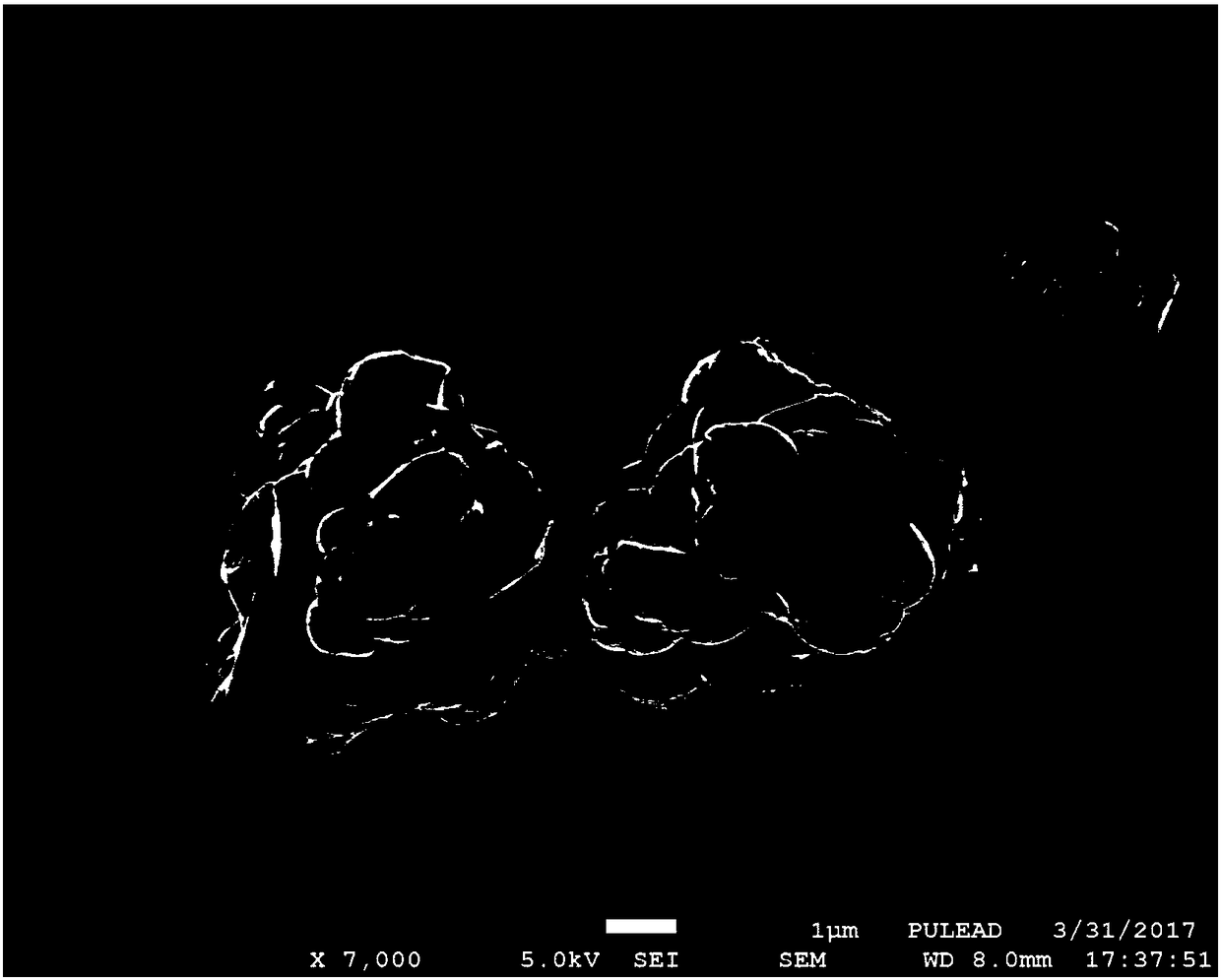

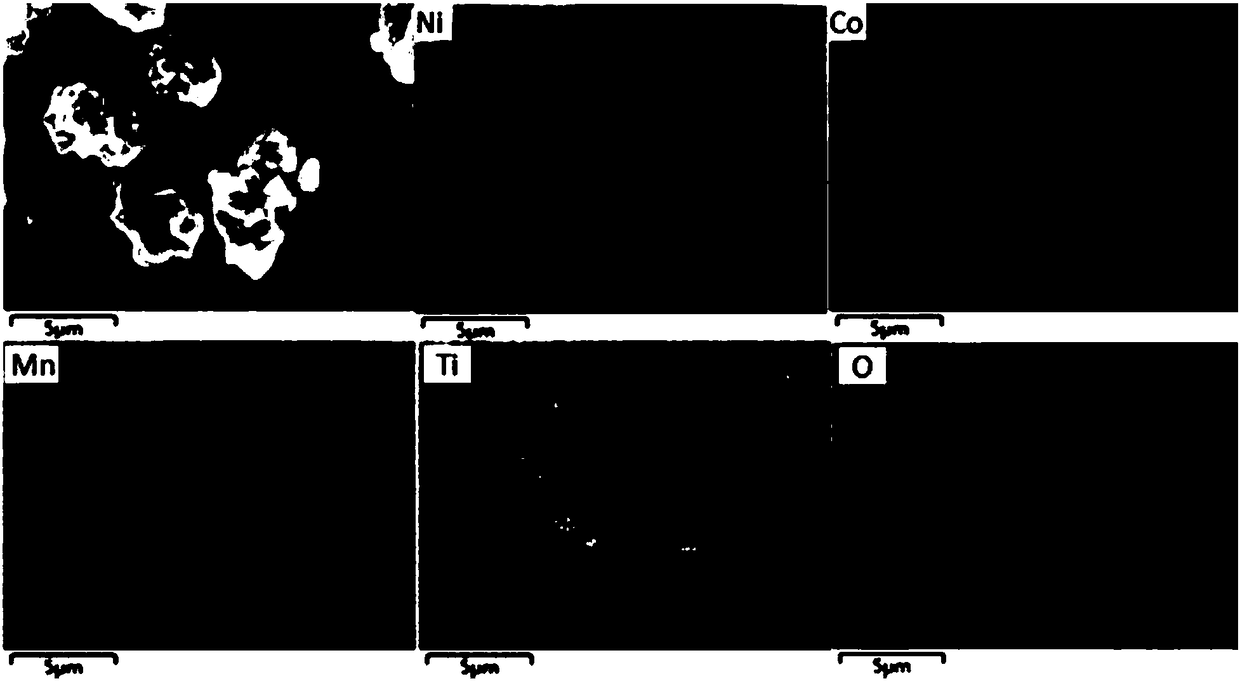

[0056] figure 2 and image 3 Respectively for the large grain body LiNi prepared in this embodiment 0.5 co 0.2 mn 0.3 o 2 / TiO2 composite scanning electron microscope image, figure...

Embodiment 2

[0059] The preparation method is the same as in Example 1, and the precursor is Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 , after the precursor and lithium source were mixed, the sintering temperature was 850°C and the time was 8h; after the intermediate product was mixed with the modification additive and binder, the sintering temperature was 1010°C and the time was 8h. The test method is the same as that of Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com