Full-automatic feeding and discharging impurity removing system for silos

A fully automatic, feeding and discharging technology, applied in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve problems such as product quality impact, raw material storage and use management risks, and inability to effectively remove them. To achieve the effect of simple production, reasonable structure, and clean materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

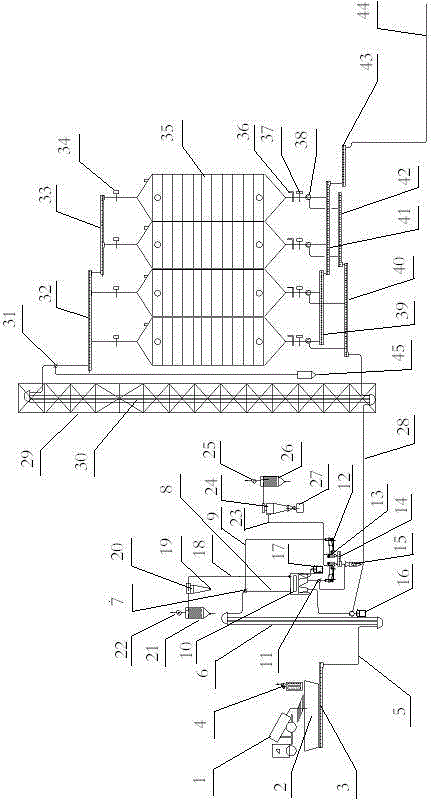

[0009] Such as figure 1 As shown, on the basis of the existing dust removal equipment for materials entering the silo, a primary dust removal system consisting of an air locker 19, a Shacron 20, a drum pulse dust collector 21 and a centrifugal fan 22 is added to the double-drum initial cleaning screen 10. device, and a pair of high-efficiency vibrating screens 12 are added between the outlet of the double-drum initial cleaning screen 10 and the hoist 30, one of which passes through the pneumatic tee 11 and the side outlet of the double-drum initial cleaning screen 10 One is connected to each other through the transmission pipeline 9 and the pneumatic tee 7 arranged in front of the double-barrel initial cleaning screen 10, and the scraper 14 is set under the discharge port of the high-efficiency vibrating screen 12, and is connected to the transmission pipeline 28 through the funnel 15. Two high-efficiency vibrating screens 12 are also provided with a set of secondary dedusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com