Intelligent printing trolley

A technology of inkjet painting and trolley, which is applied in the field of inkjet painting, can solve the problems of not being able to meet the display requirements, etc., and achieve the effect of fast inkjet printing, high inkjet accuracy and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

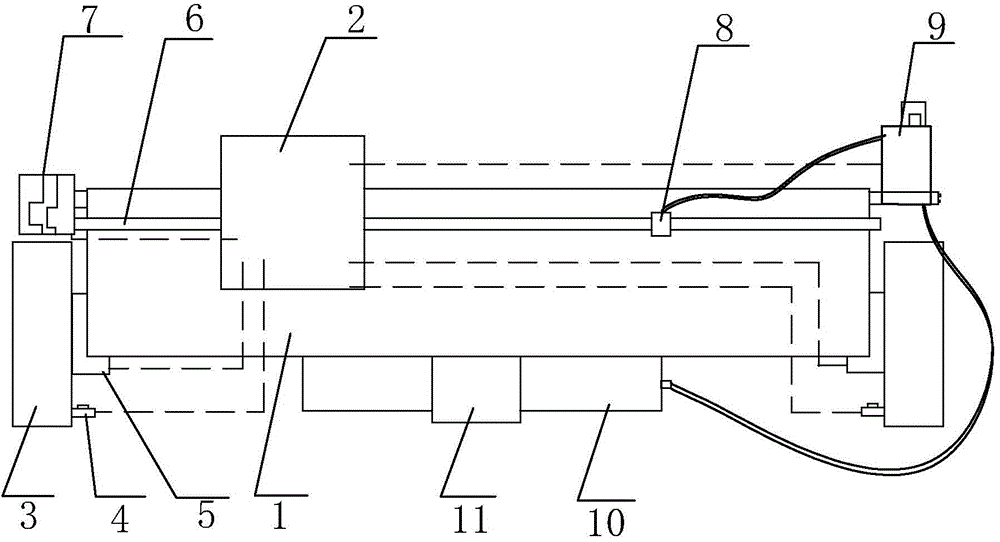

[0014] like figure 1 As shown, it is a structural schematic diagram of an intelligent inkjet cart according to the present invention, which includes a vehicle frame 1 and a single-chip microcomputer 2. Wheels 3 are arranged on the left and right sides of the bottom of the vehicle frame 1, and infrared tracking sensors are arranged on the sides of the wheels 3. 4 and wheel stepping motor 5. The tracking sensor shown is used to detect the black line on the canvas or the ground, and sends the signal to the single chip microcomputer 2, and the wheel stepping motor 5 shown is used to control the forward, backward or left and right movement of the wheel 3. The upper part of the vehicle frame 1 is provided with a sliding screw 6 spanning between the left and right sides of the vehicle frame 1, and the sliding screw 6 is connected with the sliding screw stepper motor 7 arranged on the vehicle frame 1. The rod 6 is provided with a sliding nozzle 8 that can move left and right with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com