Trailer control valve with external pressure regulating structure

A technology of control valve and pressure regulating piston, applied in the direction of control valve and air release valve, brake, brake components, etc., can solve the problems of unrealistic adjustment and inability to adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

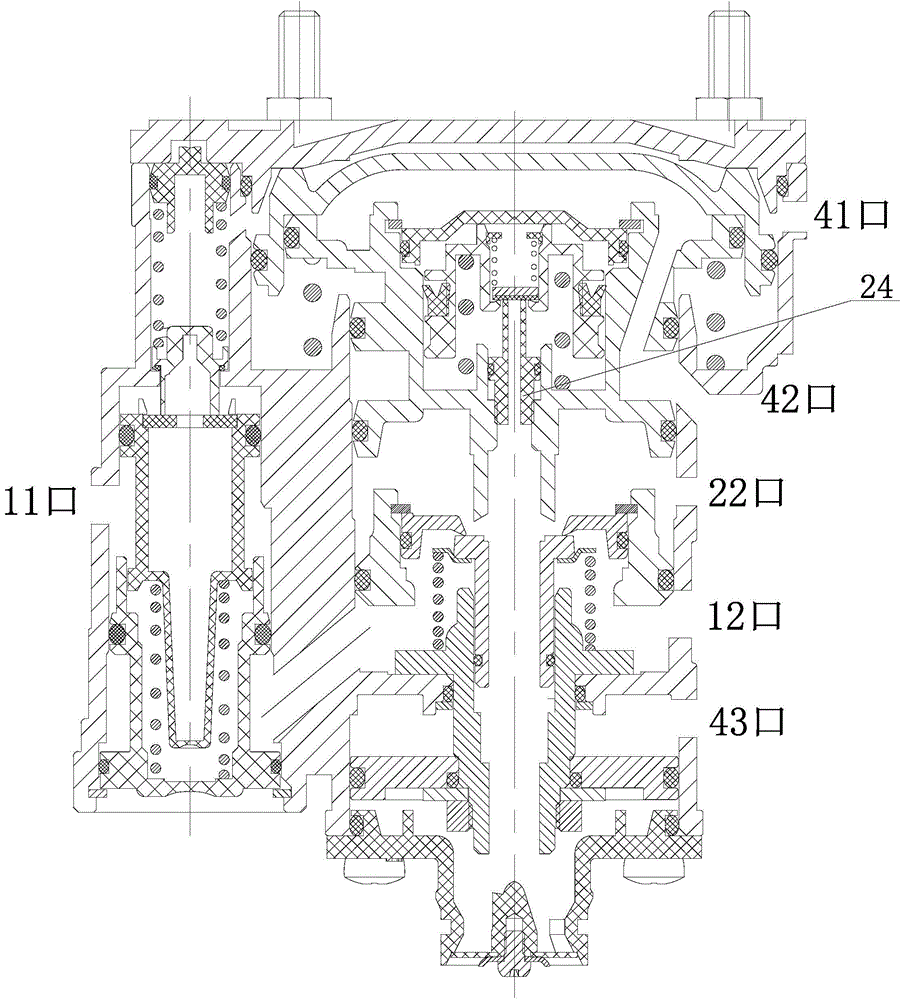

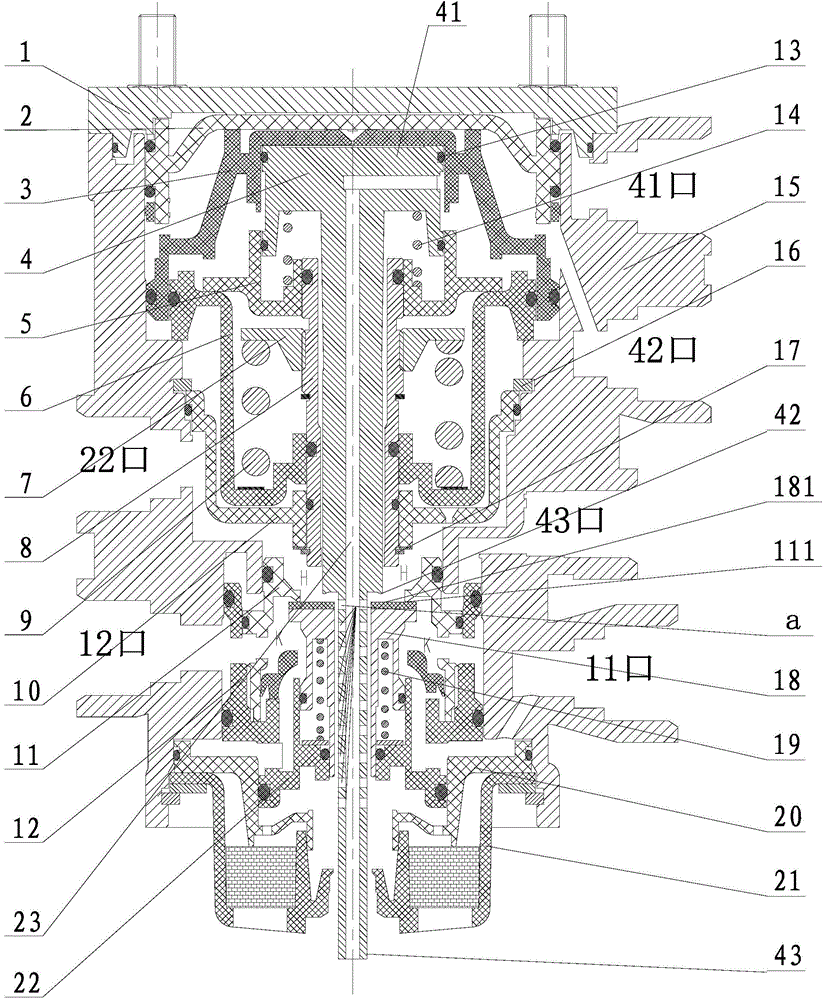

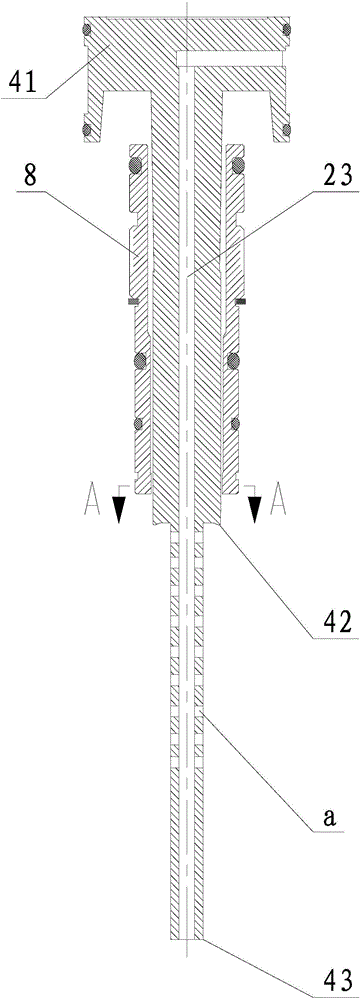

[0021] Figure 2 to Figure 6 Among them, a trailer control valve with an external pressure regulating structure, including an upper cover 1, a valve body 15, an exhaust valve port 42, an intake valve port 111 of an inner valve seat 11, an exhaust seat 20, a connecting Loop control port 41 ports, connected 42 ports for circuit control, 43 ports for manual valve control, 11 ports for air source input, 12 ports for output port connected to trailer joint and 22 ports for output port connected to emergency relay valve, exhaust seat 20 is fixed to the lower end of valve body 15 Connection, the exhaust seat 20 is connected with an exhaust cover 21, the upper part of the inner cavity of the valve body 15 is respectively provided with an outer piston 2, an inner piston 3, and the outer piston 2, the inner piston 3 and the inner wall of the inner cavity of the valve body 15 A sealing ring is provided, and the outer piston 2 and the inner piston 3 can move up and down in the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com