Gas jet expansion actuating system and control method

An actuating system and gas injection technology, applied in pipeline systems, gas/liquid distribution and storage, machines/engines, etc., can solve problems such as increasing design difficulty, strength requirements that are not conducive to weight reduction, and high risk of high pressure. Simple structure, convenient control and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

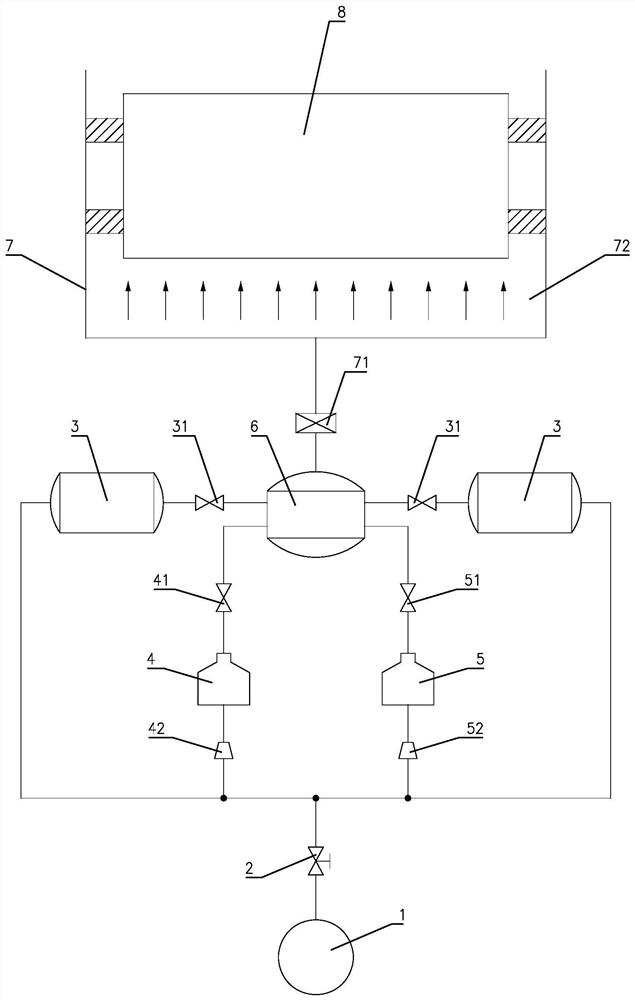

[0024] Such as figure 1 Shown is a specific embodiment of a gas injection expansion actuation system of the present invention, including a supercharger 1, a boost control valve 2, a first storage tank 3, a second storage tank 4, a third storage tank 5, and a reactor 6 And guide cylinder 7. The boost control valve 2 is connected to the supercharger 1, and the boost ports of the first storage tank 3, the second storage tank 4, and the third storage tank 5 are respectively connected to the boost control valve 2 through pipelines, so that the first The liquid outlets of the first storage tank 3 , the second storage tank 4 and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com