Rail type rope traction aerial passenger device

An overhead passenger device and rope traction technology, which is applied in cable railways, transportation and packaging, motor vehicles, etc., can solve the problems of poor stability, high cost, and many consumables, and achieve good stability, simple structure and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

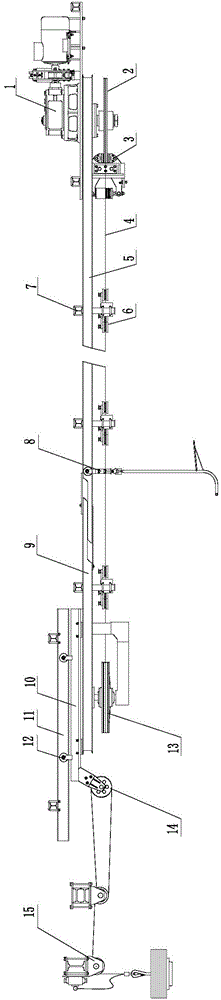

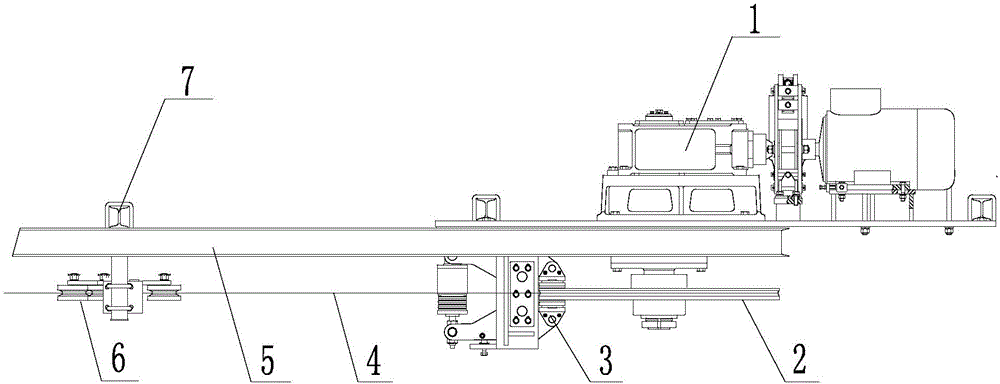

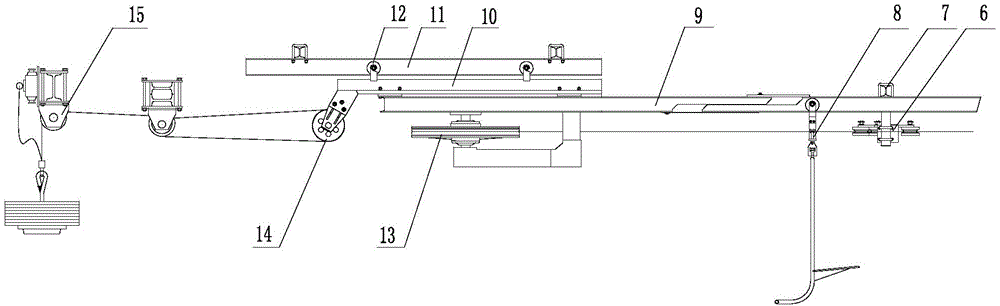

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, a track-type rope traction overhead passenger device, the track-type rope traction overhead passenger device uses a beam 7 as a mounting bracket, and a track 5 parallel to the traction wire rope 4 is installed above the traction wire rope 4. The steel wire rope 4 pulls the passenger device 8 to run on the track 5, the middle section of the traction steel wire rope 4 is stabilized and guided by the supporting pressure rope wheel device 6, and the tail wheel 13 is installed on the tensioning device; the supporting pressure rope wheel device 6, It includes a bracket 17, on which a set of relative pressure sheave assemblies are installed, and the pressure sheave assembly includes two staggered relative rotating swing arms 18, and the rotating swing arms 18 are mounted on the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com