Air inflation sealing device of rail train door and control method thereof

An air-tight sealing technology for rail trains, which is applied to door devices, transportation and packaging, and railway car body components. It can solve problems such as internal and external pressure differences, affect driving safety, and reduce passenger comfort, achieving low cost and improving comfort. , The effect of small installation space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

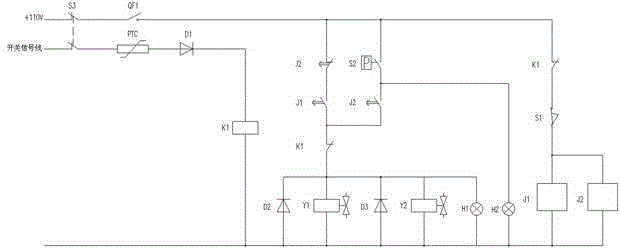

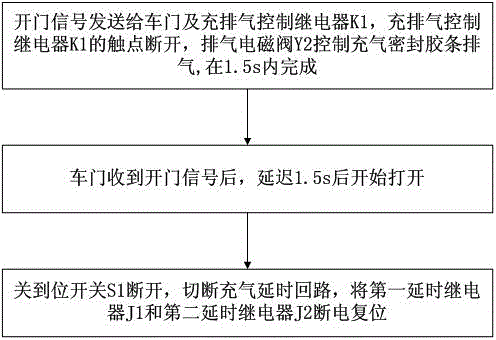

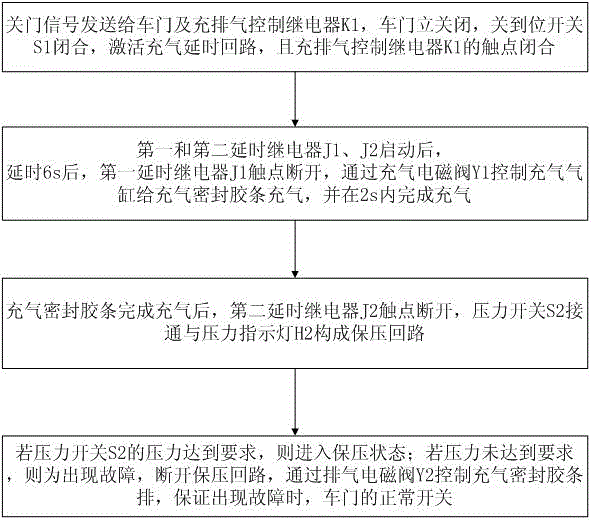

[0030] Such as figure 1 As shown, the rail train door inflatable sealing device of the present invention includes a charge and exhaust control relay K1, a first time delay relay J1, a second time delay relay J2, a door close limit switch S1, a pressure detection switch S2, and an inflation solenoid valve Y1 , exhaust solenoid valve Y2, pressure indicator light H2 and inflatable sealing rubber strip, the charging and exhausting control relay K1 is connected in series on the train door switch signal line, and the contact of the charging and exhausting control relay K1 passes through the door. The in-position switch S1 is respectively connected with the first time delay relay J1 and the second time delay relay J2, the coils of the first time delay relay J1 and the second time delay relay J2 are connected in parallel, and the contact of the second time delay relay J2 poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com