Tensioning device of adhesive tape conveyor

A technology of belt conveyor and tensioning device, which is applied in the direction of transportation, packaging, and conveyors. It can solve the problems of limited adjustment positions of the head wheel and tail wheel, and it is not suitable to install tensioning devices, so as to reduce labor intensity and reduce production accidents. , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

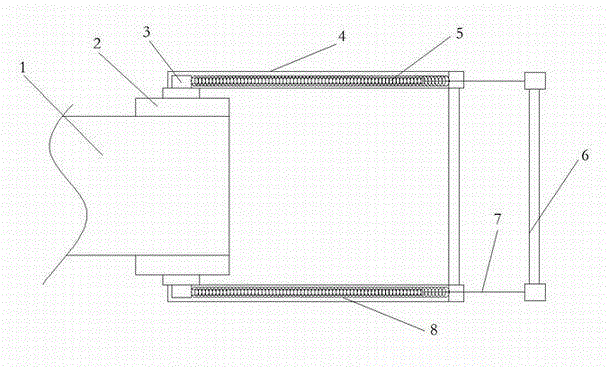

[0012] Such as figure 1 As shown, a belt conveyor tensioning device includes a conveyor belt 1, a tension wheel 2, a slider 3, a guide rail 4, a limit lever 5, a tensioning winch 6, a twisted rope 7 and a return spring 8, and the conveyor belt 1 Covering the outer edge of the tensioning wheel 2, the two ends of the tensioning wheel 2 are provided with sliders 3, the sliders 3 are in contact with the guide rail 4, the tensioning winch 6 is arranged at the end of the guide rail 4, and the slider 3 is provided with a limit rod 5 to limit One end of the position bar 5 is connected with the slide block 3, and the other end of the position bar 5 is provided with a twisted rope 7, which is connected with the tensioning winch 6, and the outer edge of the space bar 5 is provided with a return spring 8, and one end of the back spring 8 is connected with the slide block. Block 3 is connected, and the other end of back-moving spring 8 is connected with guide rail 4 ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com