Automatic tensioning system of belt conveyor and applications thereof

A belt conveyor and tensioning system technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of inability to have a large telescopic length, inability to achieve rapid tensioning, and poor dynamic adjustment performance. , to achieve no hard impact, improve dynamic stability, and reduce fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

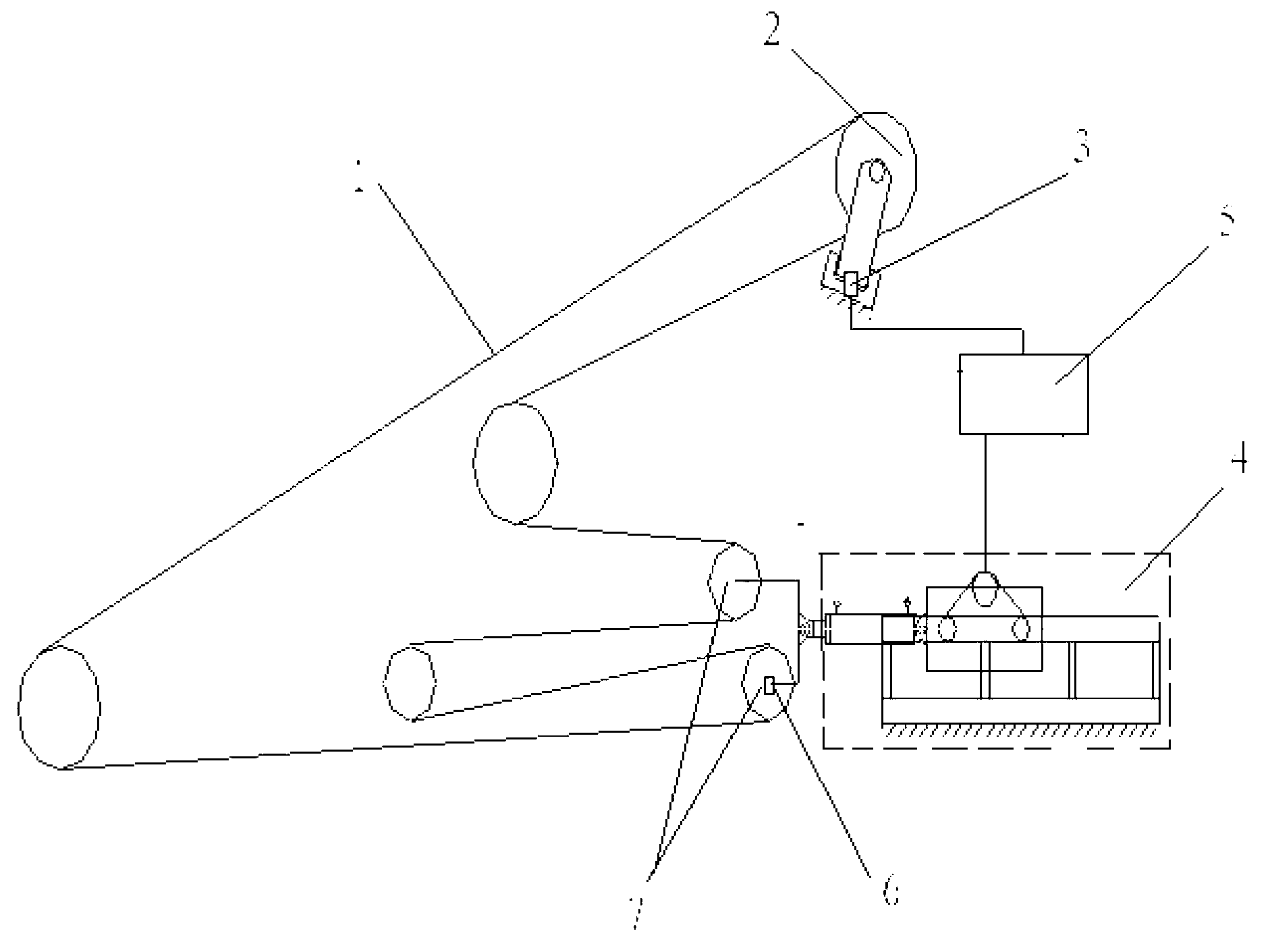

[0035] like figure 1 The shown intelligent self-moving belt tensioning system includes a tensioning device 4 and a speed acquisition device 6 installed on the tensioning drum 7 of the belt conveyor 1, and a speed acquisition device 6 installed under the support of the belt conveyor 1 driving drum 2 Tension sensor 3, and the electric control system 5 with PLC controller as core; Wherein,

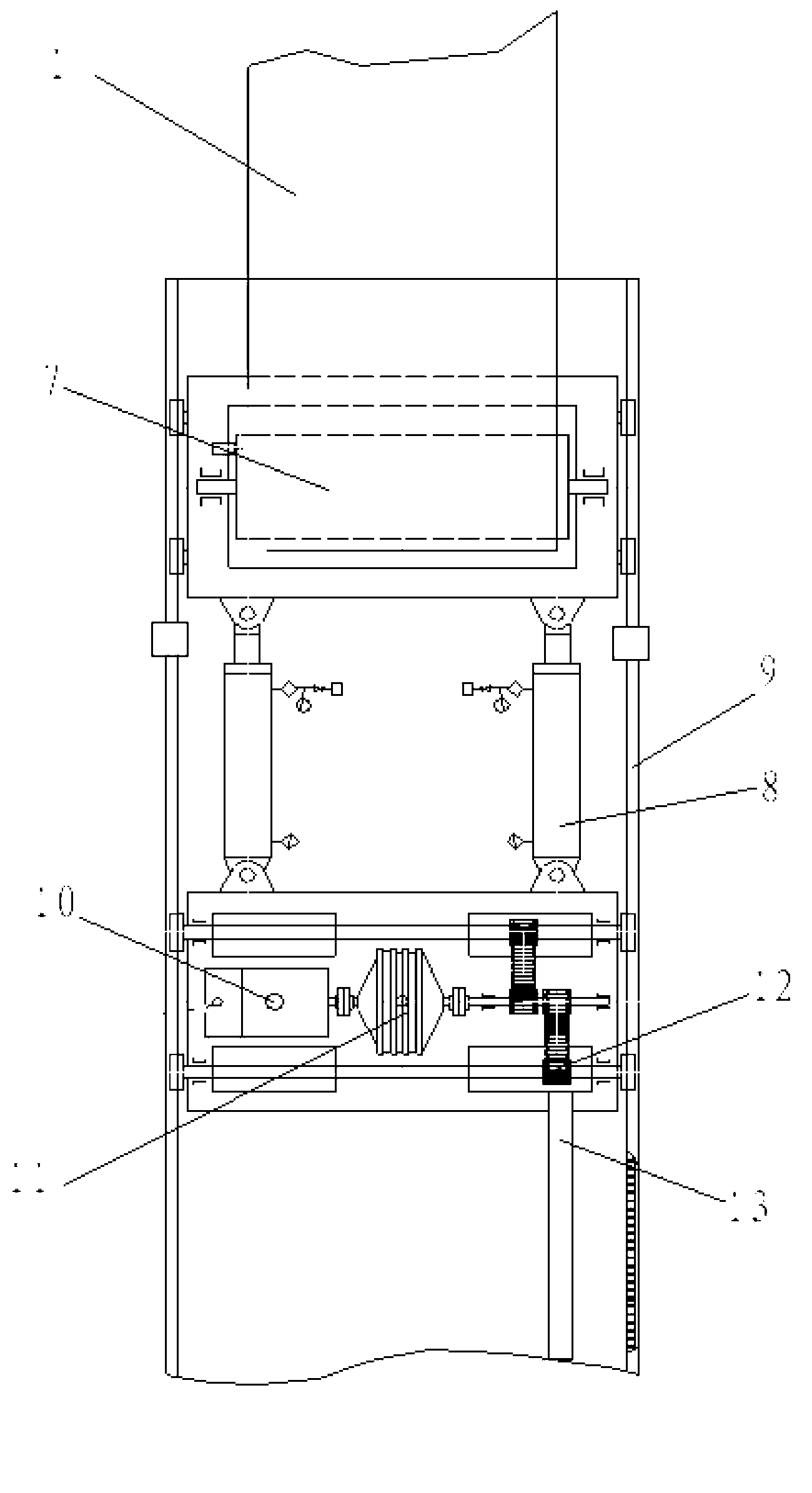

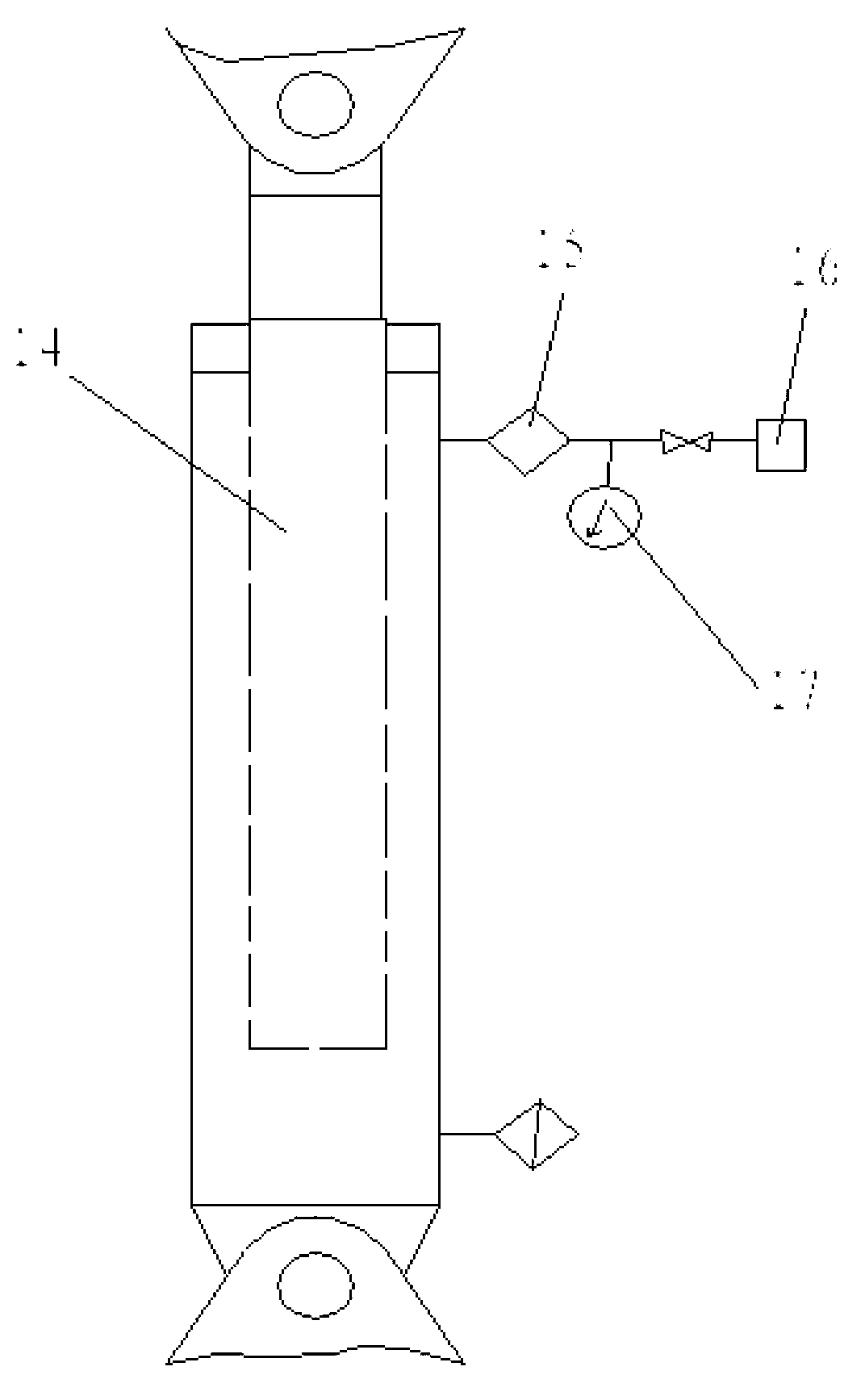

[0036] The structure of the tensioning device 4 is as figure 2 As shown, it is provided with a guide rail 9 on a frame, and a traction trolley is arranged on the guide rail 9. Two force-measuring connection devices 8 are arranged at the front end of the traction trolley, and the connection between the force-measuring connection device 8 and the tension roller 7 is realized. ;The towing trolley is composed of a power drive device and a walking mechanism installed on the trolley frame, and the walking mechanism and the power drive device realize walking through mechanical cooperation;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com