Maize pulp amount-adjusting conveyor

A technology for conveyors and corn dregs, which is applied in the directions of transportation and packaging, solid materials, loading/unloading, etc. It can solve the problems of broken corn dregs, troublesome calculations, and failure to meet the requirements of corn dregs particles, achieving fast feeding speed, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following is a detailed description of the specific implementation invention For further details:

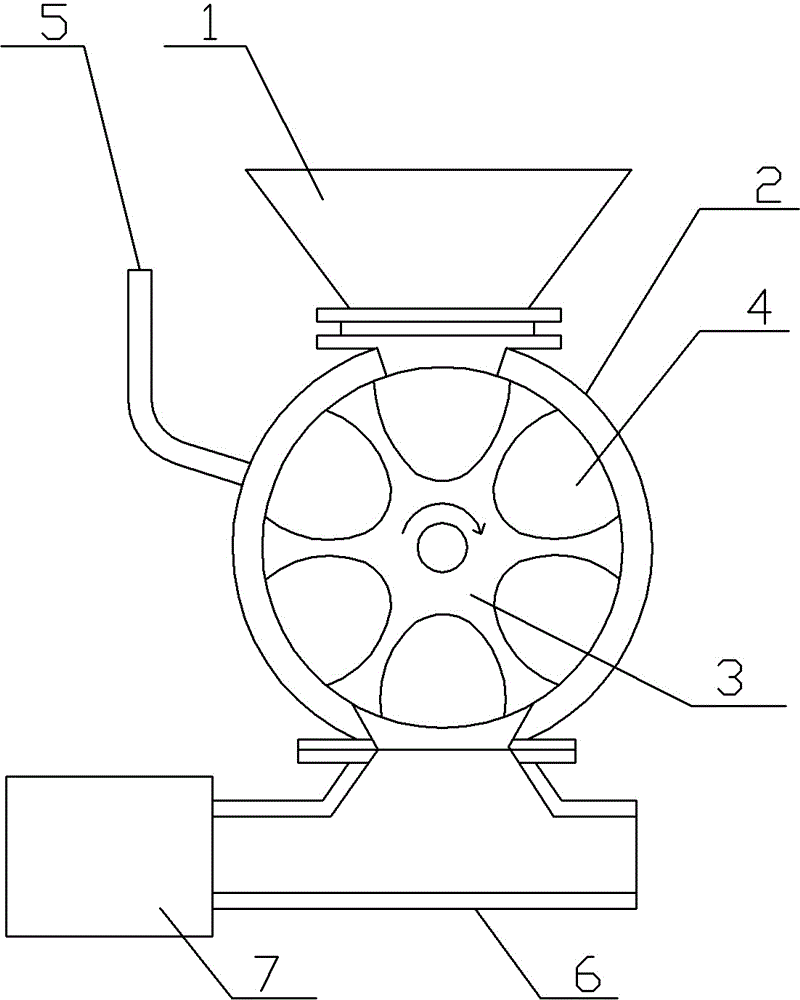

[0011] manual In the attached picture of Attached picture The marks include: hopper 1, cylinder 2, sheave 3, feeding trough 4, air pressure pipe 5, conveying pipe 6, compressed air machine 7.

[0012] The embodiment is basically as Attached Show: Corn dregs adjusting conveyor , including a frame and a hopper 1, the hopper is installed on the upper end of the frame, and the outlet of the hopper is vertically downward. A cylinder is installed on the frame, the inlet at the upper end of the cylinder communicates with the outlet of the hopper, and the outlet at the lower end of the cylinder communicates with the conveying pipe 6 arranged horizontally. The hopper and the cylinder are connected by a flange, and the cylinder and the conveying pipe are also connected by a flange. There is an air pressure balance hole on the cylinder wall of the cylinder, and the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com